Preparation method and application of cobalt disulfide and carbon nano fiber composite material

A carbon nanofiber, composite material technology, applied in the directions of carbon fiber, fiber treatment, fiber chemical characteristics, etc., can solve the problems of long charge-discharge cycle, low capacity density, low power density, etc., and achieves fewer synthesis steps, simple operation methods, The effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 (best embodiment)

[0034] A preparation method of a cobalt disulfide and carbon nanofiber composite material that can be used as an electrode material for a supercapacitor, the specific steps are as follows:

[0035] (1) The spinning solution is a polyacrylonitrile (PAN, Mw=150,000) solution with a concentration of 10%, using N-N dimethylformamide (DMF) as a solvent, stirring for 12 hours, sucking the mixed PAN solution into a syringe, and electrospinning The wire conditions are: voltage 12.5kv, flow rate 0.5mL / h, inner diameter of the needle tube 0.8mm, distance from the needle to the aluminum foil, that is, the receiving distance is 10cm. The spinning time was 10 hours. Cut the white film obtained after spinning into 2*15cm long strips and place them in a tube furnace for pre-carbonization. The conditions are: in an air atmosphere at room temperature 1 °C / min rise to 270 °C, keep warm for 2 hours, and cool to room temperature. Then carry out the carbo...

Embodiment 2

[0043] Embodiment 2 (comparative example)

[0044] A preparation method of a cobalt disulfide and carbon nanofiber composite material that can be used as an electrode material for a supercapacitor, the specific steps are as follows:

[0045] (1): This step is exactly the same as Example 1.

[0046] (2) Hydrothermal process: Weigh 20 mg of carbonized carbon fiber, activate it with concentrated nitric acid for 12 hours, add 0.1 g of cobalt nitrate hexahydrate and 0.05 g of thioacetamide into 20 mL of deionized water, dissolve it with ultrasonic waves, and activate After washing the carbon fiber with water, add it to 20mL solution, transfer the solution to a 35mL reaction kettle, put it in an oven, Reaction at 140℃ for 1h, 3h, 5h . After the reaction, after the reactor was cooled, the carbon fiber was taken out, washed several times with distilled water and ethanol respectively, and vacuum-dried at 60° C. to obtain a composite material.

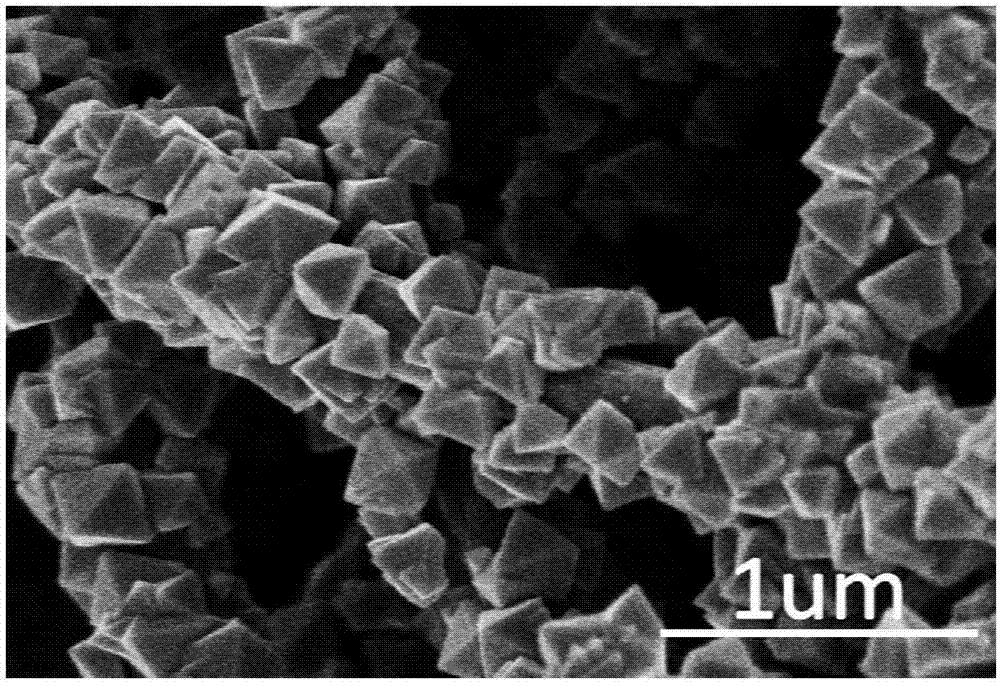

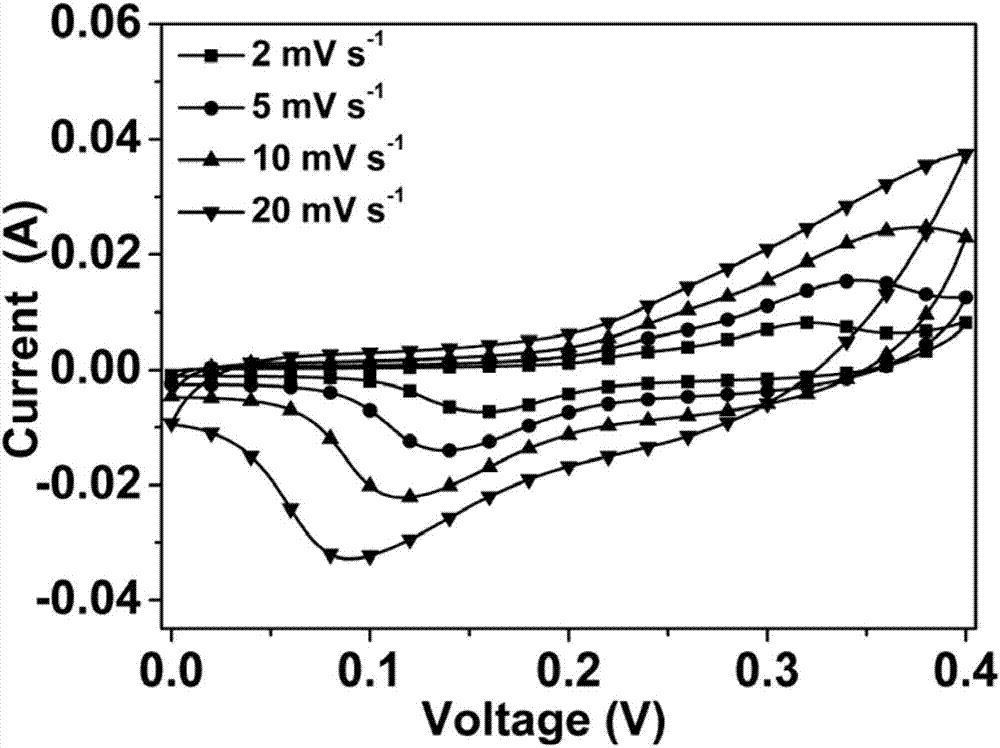

[0047] The SEM photos of cobalt disul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com