Handheld double-component high-pressure glue-injection machine

A two-component, hand-held technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of uneven mixing and insufficient glue injection, so as to ensure the construction quality, facilitate glue injection, increase the The effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

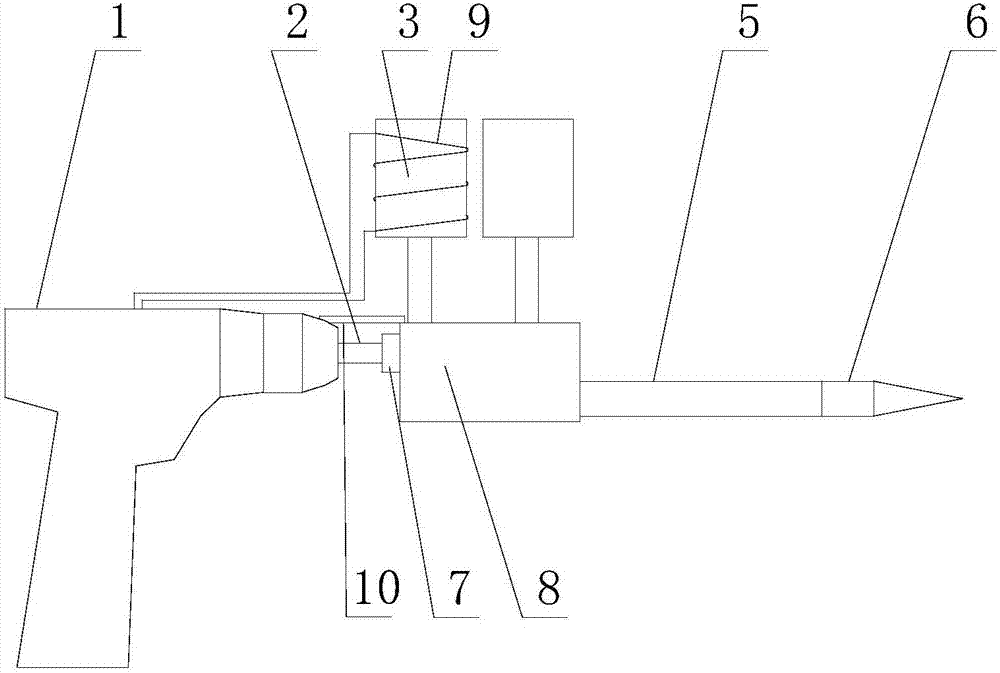

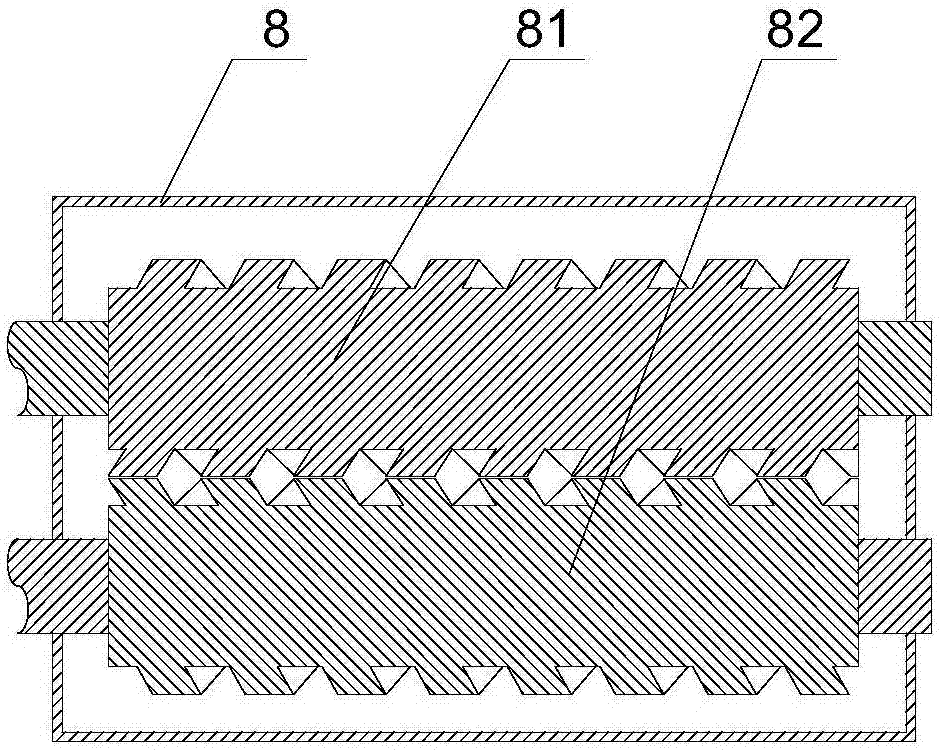

[0031] see figure 1 , Figure 4 , a hand-held two-component high-pressure glue injection machine, which includes a material screw-in drive device 1, the output shaft 2 of the material screw-in drive device is fitted with one end of the material mixing screw-in chamber 8, and the material mixes screw-in A screw-in screw 81 is installed in the bin, and the screw-in screw is connected to the output shaft; the other end of the material mixing screw-in bin is connected to the rubber injection pipe through the material outlet; the material mixing screw-in bin is connected to at least one feeder Barrel 3; present embodiment is provided with two feeding barrels, a liquid material feeding barrel, a powder material feeding barrel, and the liquid material feeding barrel is arranged on the left side of the powder material feeding barrel; the liquid material first enters The material is mixed and screwed into the bin, and then the powder enters the material mixed and screwed into the bin,...

Embodiment 2

[0038] see figure 1 , figure 2 , image 3 , The handheld two-component glue injection machine in this embodiment is an improvement on the basis of Embodiment 1. The technical content disclosed in Embodiment 1 will not be described repeatedly, and the content disclosed in Embodiment 1 also belongs to the content disclosed in this embodiment. .

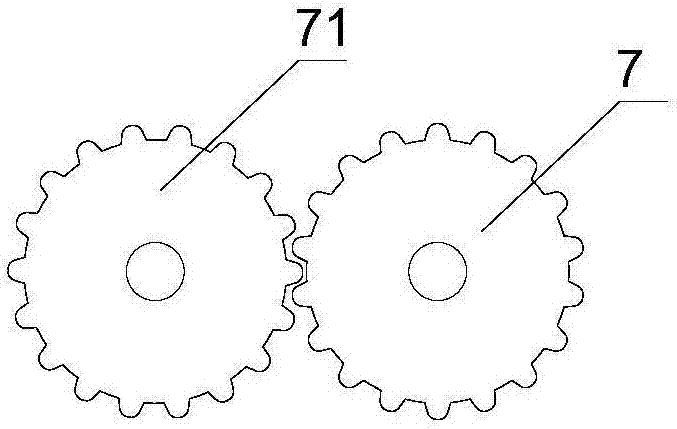

[0039] see figure 2 , image 3, also includes an auxiliary stirring propulsion assembly, which includes an auxiliary screw 82 worn in the material mixing screw-in bin; one end of the auxiliary screw passes out of the material mixing screw-in bin, and passes through the output shaft Install the driving gear 7, wear the driven gear 71 meshed with the driving gear on the auxiliary screw rod; the driving gear drives the driven gear to rotate to drive the auxiliary screw rod to rotate; promote the further mixing of materials .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com