Ternary-composite solar steam generation device and application thereof

A technology of solar steam and ternary compounding, which is applied in the field of nanotechnology and photothermal conversion materials, can solve problems such as the inability to break through in photothermal conversion efficiency and heat loss of thin films, achieve great commercial value and application prospects, reduce heat loss, and install The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

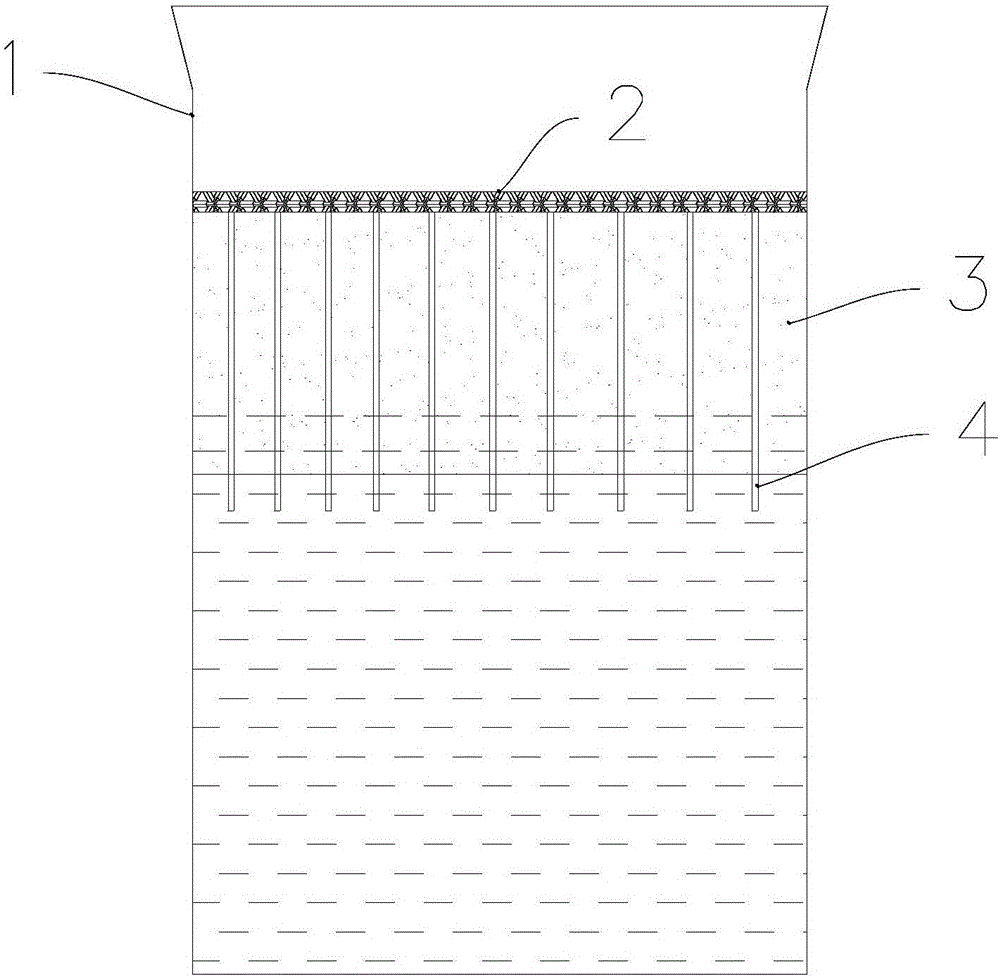

[0032] like figure 1 As shown, the present invention provides a ternary composite solar steam generating device, which includes a water container 1, a light-to-heat conversion film 2, a heat insulation board 3 and a water delivery pipeline, water is housed in the water container 1, Only the lower part of the heat insulation board 3 is immersed in water, and the upper part is located above the water surface. The light-to-heat conversion film 2 covers the upper surface of the upper part of the heat insulation board 3 . Uniform and dense capillary tubes 4 , the lower openings of the capillary tubes 4 are immersed in water, and the upper openings of the capillary tubes are close to or in contact with the light-to-heat conversion film 2 .

[0033] Specifically, the water container 1 is a glass container with an open top, the light-to-heat conversion film 2 is a reduced graphene oxide-based light-to-heat conversion film, and the heat insulation board 3 is made of foamed polyethylene...

Embodiment 2

[0035] like figure 1 As shown, the present invention provides a ternary composite solar steam generating device, which includes a water container 1, a light-to-heat conversion film 2, a heat insulation board 3 and a water delivery pipeline, water is housed in the water container 1, The heat insulation board 3 is located above the water surface as a whole and the lower surface is separated from the water surface. The light-to-heat conversion film 2 is located above the heat insulation board 3 and the heat insulation board is not in contact with the light-to-heat conversion film. The uniform and dense capillaries 4 of the heat shield 3 , the lower openings of the capillaries 4 are immersed in water, and the upper openings of the capillaries are close to or contact the light-to-heat conversion film 2 . In the above structure, the heat insulation board 3 and the light-to-heat conversion film 2 are fixed by any method that those skilled in the art can think of, such as by bonding o...

Embodiment 3

[0038] It is basically the same as Example 1, more specifically: the glass container is a beaker, the heat shield is a cylinder and its diameter is the same as the inner diameter of the beaker, the diameter of the heat shield is 40mm, the height is 15mm, the capillary length is 30mm, and the inner diameter is 0.5mm, wherein the reduced graphene oxide-based light-to-heat conversion film is prepared by the following method:

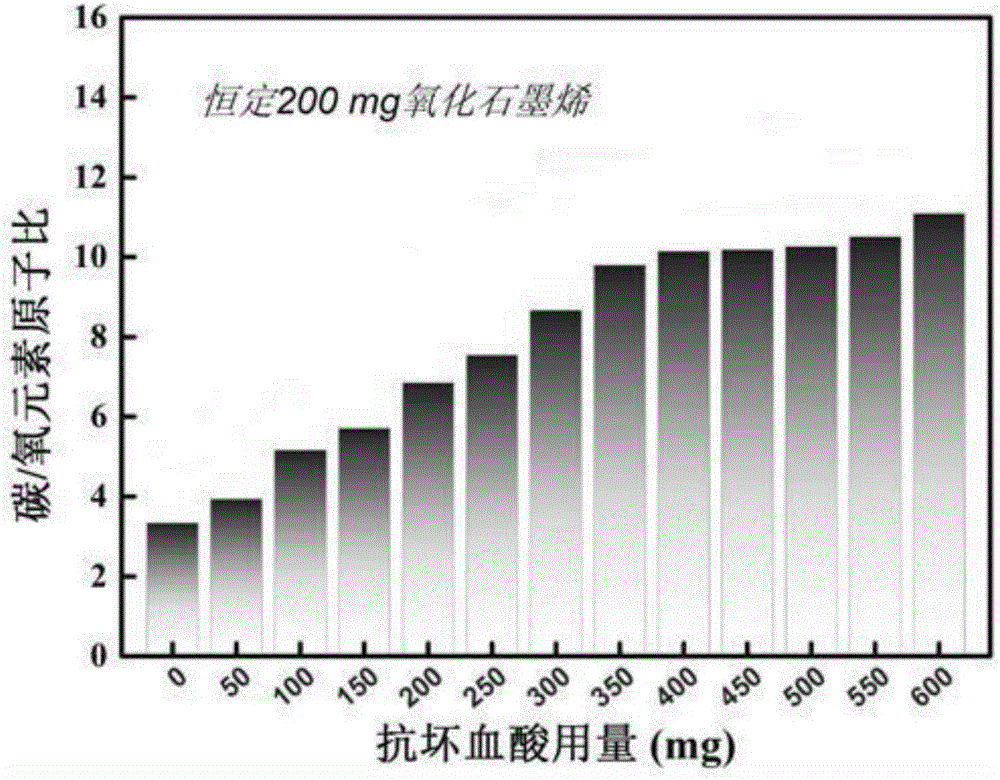

[0039] (1) Synthesis of reduced graphene oxide: 200 mg of graphene oxide and 50 mg of ascorbic acid were added to 200 ml of deionized water, and magnetically stirred for 10 minutes. The above dispersion was placed in a microwave reactor at 200W and 95°C for 10 minutes. The resulting liquid was filtered and dried to obtain reduced graphene oxide.

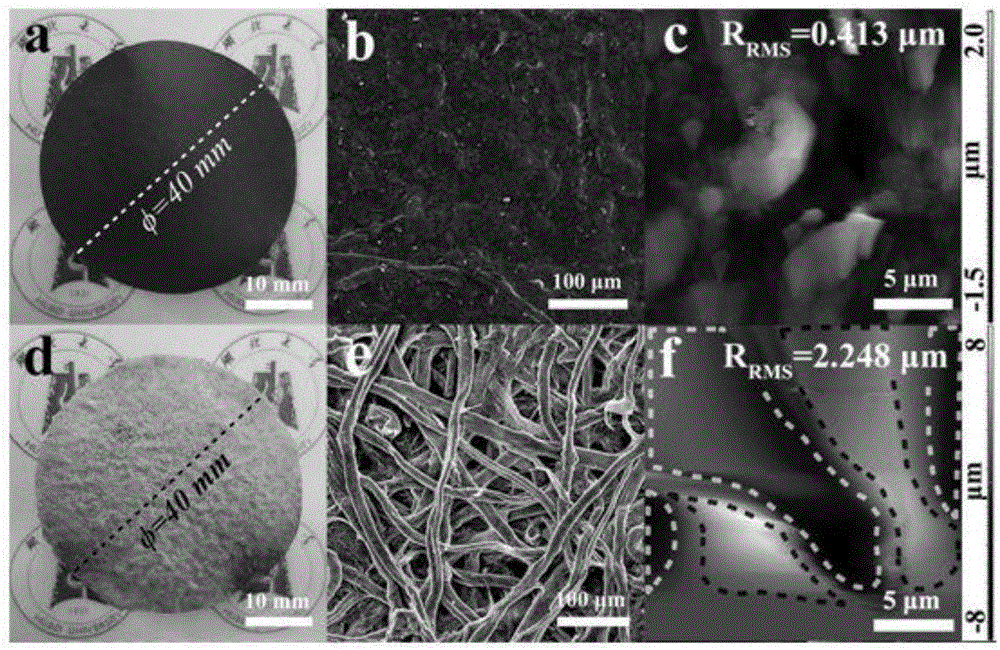

[0040] (2) Preparation of reduced graphene oxide-based light-to-heat conversion film: 100 mg of shaped filter paper was added to 100 mL of solvent, and magnetically stirred at 100° C. for 2 hours to obtain a cell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com