Layered electroforming method for slotted rectangular waveguide

A rectangular waveguide and electroforming technology, which is used in electroforming and electrolytic processes to achieve the effects of improving processing efficiency, strong process adaptability and saving processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The slotted rectangular waveguide that needs to be prepared is as Figure 10 As shown, the following preparation process is adopted:

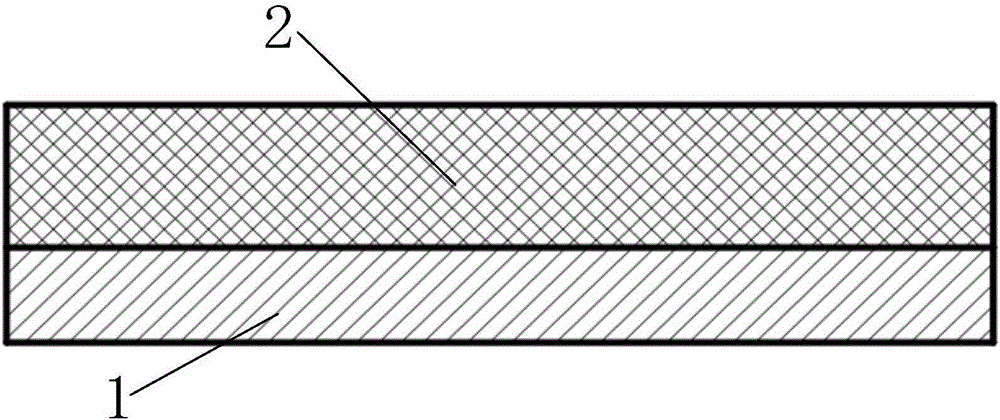

[0029] Step 1: coating a layer of photoresist 2 with a thickness of L1 on the surface of the substrate 1;

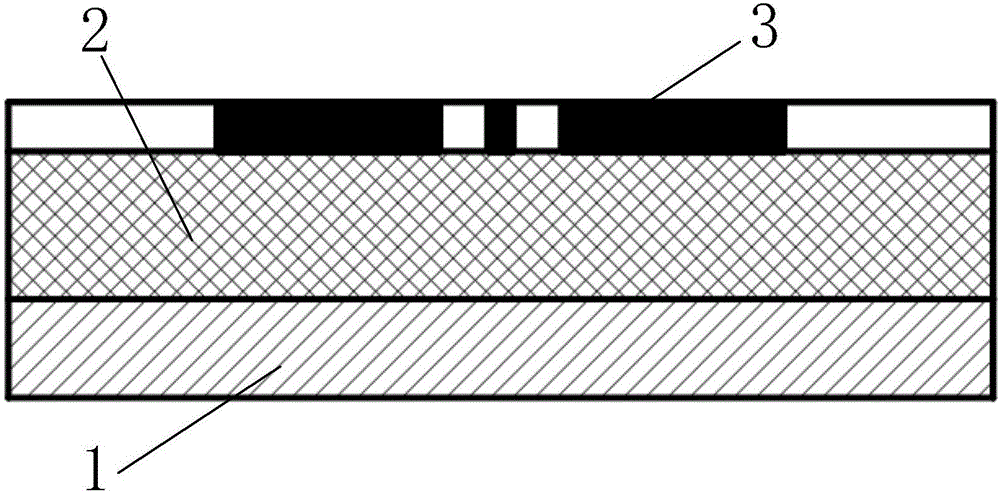

[0030] Step 2: Place the substrate 1 that has been coated for the first time in step 1 on the stage of the lithography machine, and use the first exposure mask 3 to perform the first exposure;

[0031] Step 3: Put the substrate 1 after the first exposure in step 2 into the developing solution for the first development, wash and dry after development;

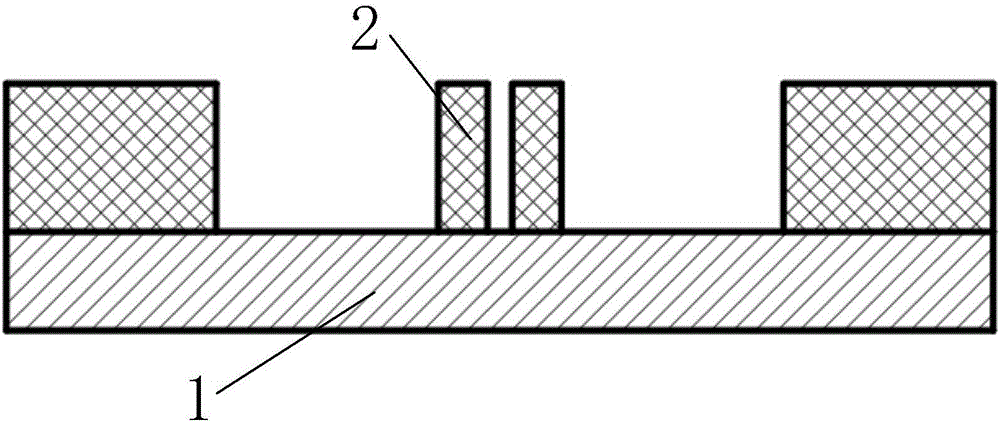

[0032] Step 4: Electroform a layer of thickness L1 on the surface of the substrate 1 after the first development in step 3

[0033] Copper 4;

[0034] Step 5: Perform precision polishing on the surface of the electroformed copper 4 in step 4 to ensure that the thickness of the first layer of copper 4 is L2;

[0035] Step 6: Coating a layer of photolithography with a thickness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com