A method and application of directly using non-detoxified acid to pretreat lignocellulose for hydrogen production

A lignocellulose and acid pretreatment technology, applied in microorganism-based methods, biochemical equipment and methods, fermentation, etc., to achieve the effects of reducing production costs, changing metabolic pathways, and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

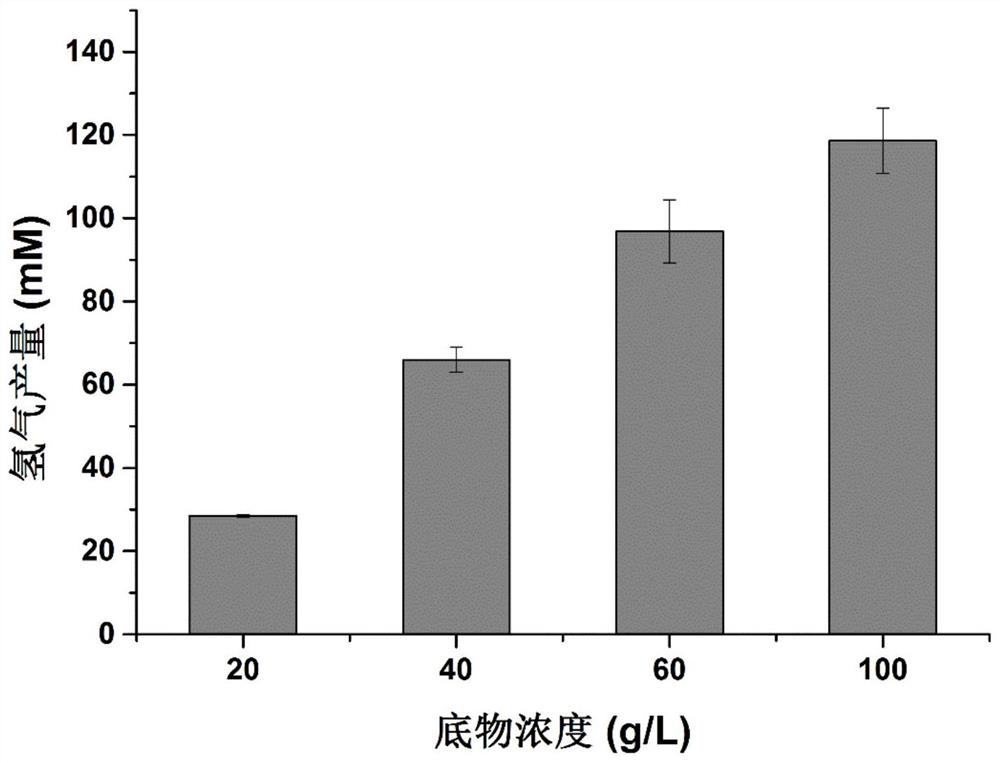

[0068] Example 1: Hydrogen production capacity of different concentration substrates in synchronous saccharification

[0069] (1) Preparation of a seed fluid of thermophilic fluid oires: The thermophilic polytenee anaerobacterium MJ1 preserved -80 ° C is first passed through 10 ml of Willin bottle (with 4.5 mL seed medium) at 55 ° C, 150 rpm oscillating culture. 18h was activated, followed by amplification at 100 mL of serum bottle (45 mL seed medium) at 55 ° C, 150 rpm oscillated culture for 18 h, resulting in seed fluid. The seed medium is a xylose liquid medium containing 5 g / L xylose. The main components of the medium are: xylose 5g / L (carbon source), 1 g / L of ammonium chloride, 1 g / L of sodium chloride, hydrogen phosphate 1 g / L of potassium, 1 g / L of phosphate, 0.5 g / L, hexamine chloride 0.5 g / L, potassium chloride 0.2g / L, yeast powder 2g / L, protein 胨 2g / L, Trual element reservoir 1 ml / L, 1ml / L of vitamin reservoir, 0.01% blade Tianqing 1ml / L;

[0...

Embodiment 2

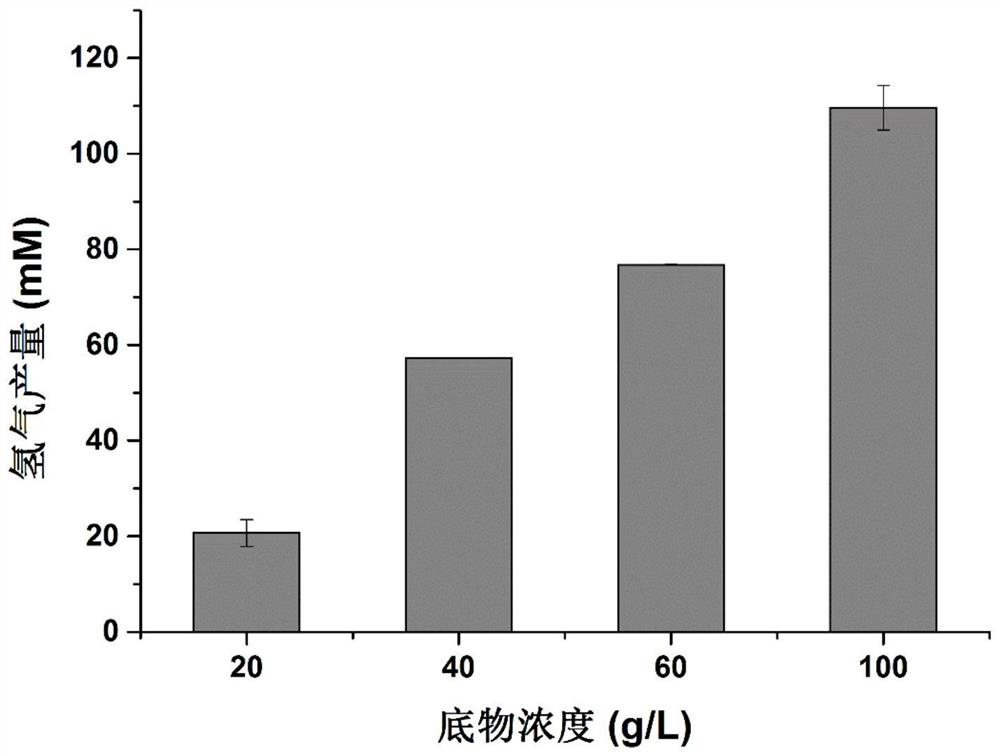

[0077] Example 2: Hydrogen production capacity of different concentration substrates in conjunctive synchronous saccharification

[0078] (1) Preparation of seed fluid as in Example 1.

[0079] (2) Preparation of fermentation medium and sterilization as in Example 1.

[0080] (3) The first stage in the preheating synchronous aerobacterial prehydration synchronous saccharide fermentation mode is hydrogenated: the cellulase CTEC2 is injected into the medium with a syringe of 20U / g canesets, and after 50 ° C is enzymatically dissociated after 72 h. Further, the prepared seed liquid was injected into the fermentation medium after 10% (V / V) inoculation, and the fermentation temperature was 55 ° C, the shaker was 150 rpm, and the fermentation was terminated after fermentation 120h. Such as figure 2 As shown, the yield of hydrogen is increased as the substrate concentration increases, and the output is 20.71 mm (20g / L sugar canesets), 57.78 mm (40 g / L sugar cane), and 76.78 mm (6...

Embodiment 3

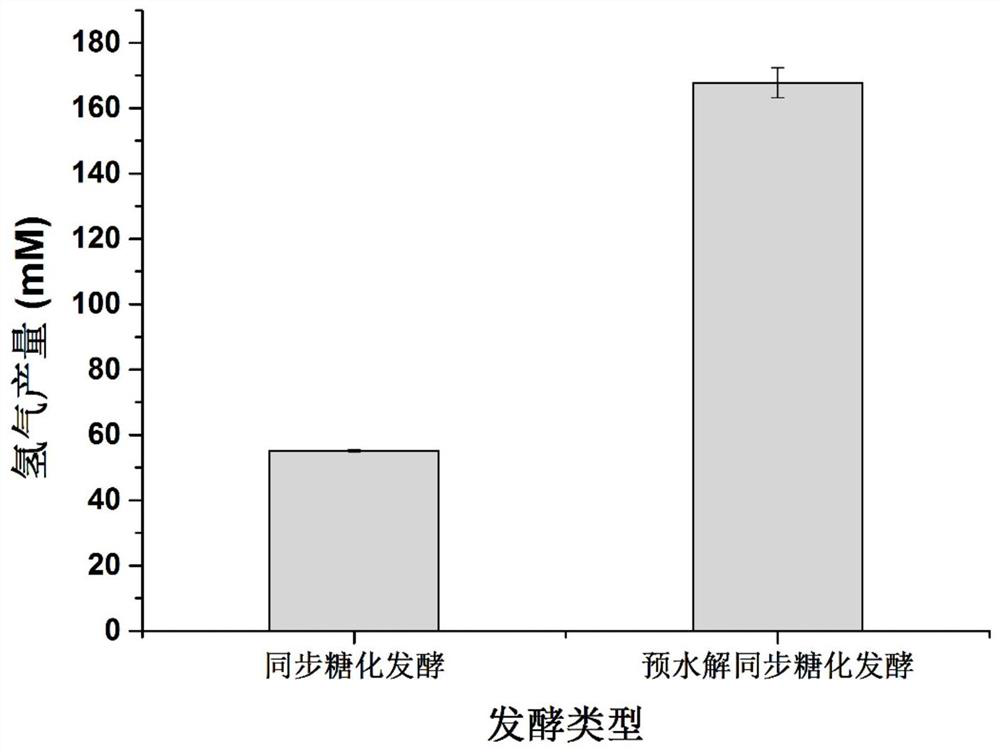

[0081] Example 3: Method for carrying hydrogen production in different fermentation modes

[0082] (1) Preparation of seed fluid as in Example 1.

[0083] (2) Preparation of fermentation medium and sterilization as in Example 1.

[0084] (3) The first stage of hydrogenation in synchronous saccharification fermentation mode in synchronous saccharification is in Example 1.

[0085] (4) EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc.

[0086] (5) Second stage fermentation hydrogen in different fermentation modes: After the end of the fermentation, synchronous glycained fermentation and prehydrolysis synchronous saccharification fermentation of the fermentation medium (100 g / L sugarcane slag) is adjusted to 7.0, The serum bottle was sealed with a glue and aluminum cover and repeatedly pumped with 0.01 MPa of nitrogen 3 times, transferred to the purity of the second stage, the fermentation temperature was 55 ° C, the shaker was 150 rpm, ferment 120h After the end of the fermentation. Such as im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com