Method for generating hydrogen directly by non-detoxified acid pretreatment lignocellulose and application

A technology for lignocellulose and acid pretreatment, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., to achieve the effects of reducing production costs, good applicability, and simplifying operating processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

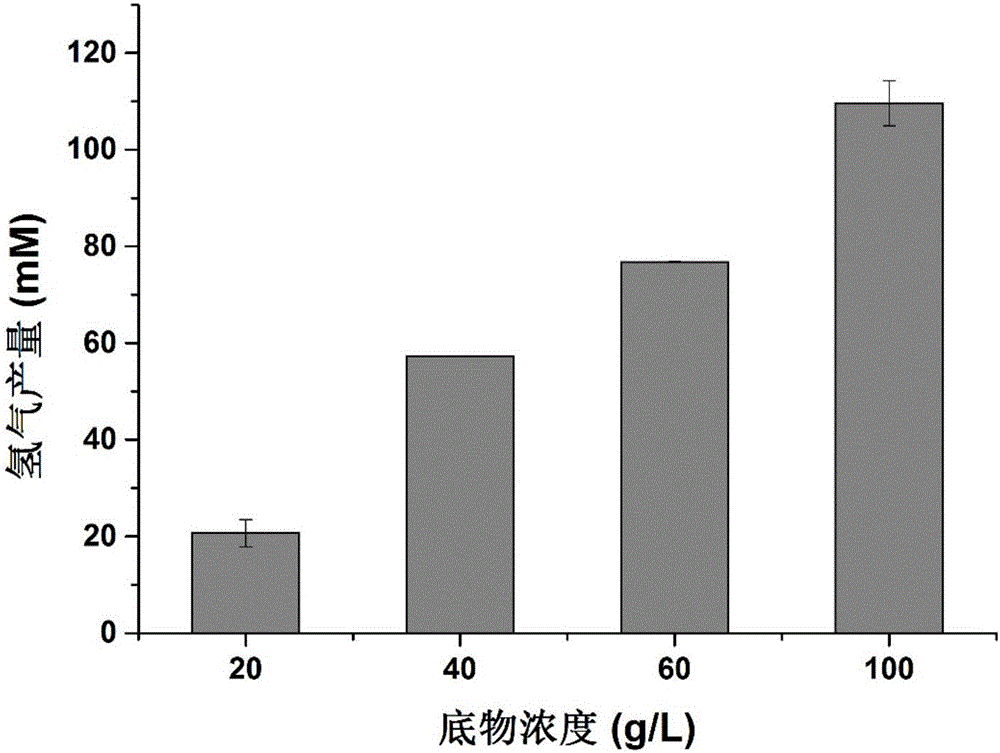

[0068] Example 1: Hydrogen production capacity of different concentrations of substrates under simultaneous saccharification and fermentation mode

[0069] (1) Preparation of the anaerobic Bacillus thermosaccharolyticum seed solution: The anaerobic Bacillus thermosaccharolyticus MJ1 stored at -80°C was cultured by shaking at 55°C and 150rpm in a 10mL vial (containing 4.5mL seed medium). Activation was carried out for 18 hours, followed by shaking culture in a 100 ml serum bottle (containing 45 mL seed medium) at 55° C. and 150 rpm for 18 hours for amplification to obtain seed liquid. Wherein the seed medium is a xylose liquid medium containing 5g / L xylose, and the main components of the medium are: xylose 5g / L (carbon source), ammonium chloride 1g / L, sodium chloride 1g / L, hydrogen phosphate Dipotassium 1g / L, potassium dihydrogen phosphate 1g / L, cysteine 0.5g / L, magnesium chloride hexahydrate 0.5g / L, potassium chloride 0.2g / L, yeast powder 2g / L, peptone 2g / L, Trace element s...

Embodiment 2

[0077] Example 2: Hydrogen production capacity of different concentrations of substrates under pre-hydrolysis synchronous saccharification and fermentation mode

[0078] (1) The preparation of the seed solution is the same as in Example 1.

[0079] (2) The preparation and sterilization of the fermentation medium are the same as in Example 1.

[0080] (3) Hydrogen production in the first stage under the prehydrolysis and synchronous saccharification and fermentation mode of thermophilic anaerobic saccharolytica: inject cellulase CTec2 into the medium with a syringe at 20 U / g bagasse, and enzymatically hydrolyze at 50°C for 72 hours Then the prepared seed solution was injected into the above-mentioned fermentation medium after enzymolysis according to the inoculation amount of 10% (v / v), the fermentation temperature was 55° C., the shaking table speed was 150 rpm, and the fermentation was terminated after 120 hours of fermentation. The result is as figure 2 Shown, the output ...

Embodiment 3

[0081] Embodiment 3: The method for carrying out the second-stage fermentation hydrogen production under different fermentation modes

[0082] (1) The preparation of the seed solution is the same as in Example 1.

[0083] (2) The preparation and sterilization of the fermentation medium are the same as in Example 1.

[0084] (3) The hydrogen production in the first stage under the synchronous saccharification and fermentation mode of thermophilic saccharolytic anaerobic bacteria is the same as in Example 1.

[0085] (4) The hydrogen production in the first stage under the prehydrolysis and synchronous saccharification and fermentation mode of thermophilic saccharolytica anaerobic bacteria is the same as in Example 2.

[0086] (5) Hydrogen production in the second stage of fermentation under different fermentation modes: after the completion of the first stage of fermentation, adjust the pH value of the fermentation medium (100g / L bagasse) to 7.0 after the simultaneous sacchari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com