Preparation method and application of polytitanium aluminum chloride-cationic polyacrylamide composite flocculant

A technology of polyacrylamide and polytitanium aluminum chloride, which is applied in the fields of chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc. Large amount, slow settling speed and other problems, to achieve good coagulation effect, strong adsorption and bridging ability, and good electrical neutralization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

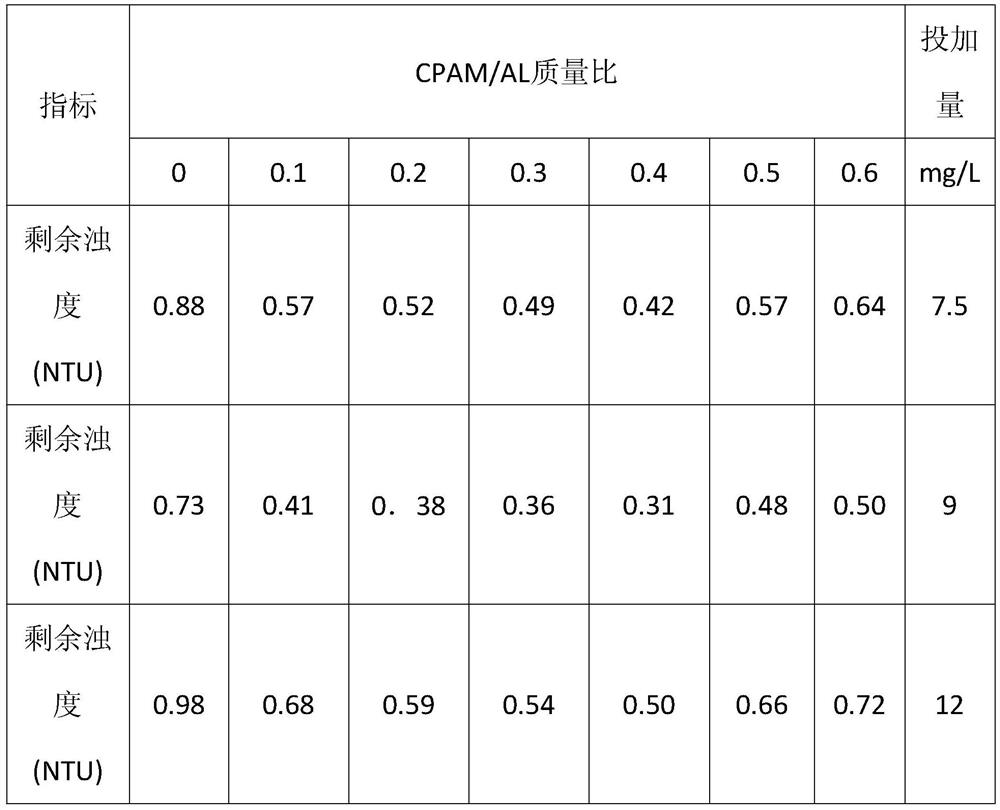

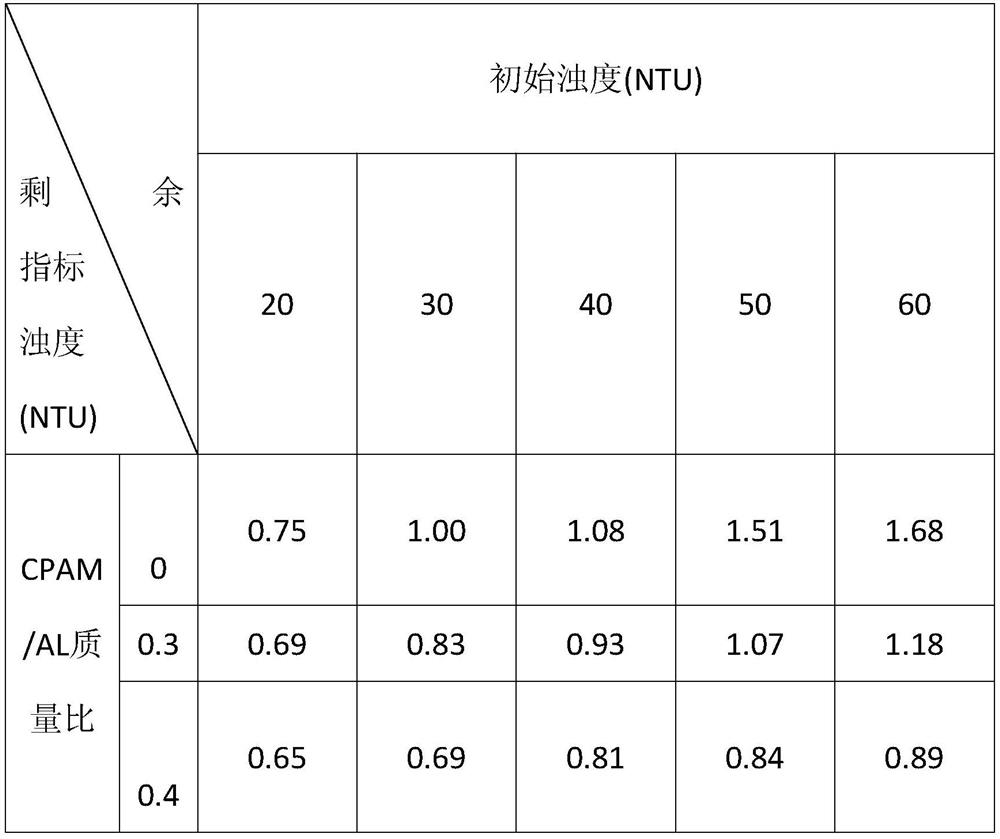

Examples

preparation example Construction

[0026] A preparation method of polytitanium aluminum chloride-cationic polyacrylamide composite flocculant, it comprises the following steps:

[0027] (1) Weigh a certain mass of polyaluminum chloride and add water to fully stir and dissolve to obtain a yellow polyaluminum chloride solution. Place the fully dissolved polyaluminum chloride solution at -20-5°C for 1- 60min;

[0028] (2) TiCl 4 Add in the polyaluminium chloride solution gained in step (1), fully stir according to OH - / Al 3+ The molar ratio of the solution is 0.05-0.35, and the sodium hydroxide solution with a concentration of 1mol / L is added dropwise. After the dropwise addition, the constant temperature water bath is continuously stirred for 2 hours to obtain a polytitanium aluminum chloride solution;

[0029](3) The cationic polyacrylamide is fully stirred and dissolved with water to obtain a colorless transparent viscous solution, and the fully dissolved cationic polyacrylamide solution is stored at a temp...

Embodiment 1

[0036] (1) Weigh 15.0000g of polyaluminum chloride (PAC) solid powder and dissolve it in about 30mL of pure water, stir well to dissolve it; place the polyaluminum chloride (PAC) solution in freezing conditions for several hours (close to freezing , about 10min).

[0037] (2) Pipette 2.8131mL of TiCl with a pipette gun 4 Solution (density 1.726g / cm 3 , TiCl 4 The relative molecular mass is 189.679) into the polyaluminum chloride (PAC) solution obtained in (1), and fully stirred to obtain a mixed solution.

[0038] (3) According to the molar ratio of OH / Al being 0.15, add a sodium hydroxide (NaOH) solution with a concentration of 1mol / L to the mixed solution in (2) dropwise. After the dropwise addition, keep stirring in a constant temperature water bath at 50°C for 2h , to obtain polytitanium aluminum chloride (PTA) solution.

[0039] (4) Weigh 5.0000 g of cationic polyacrylamide (CPAM) and dissolve it in pure water, and set the volume in a 500 mL volumetric flask to obtain...

Embodiment 2

[0041] A preparation method of polytitanium aluminum chloride-cationic polyacrylamide composite flocculant, it comprises the following steps:

[0042] (1) Weigh a certain mass of polyaluminum chloride and add water to fully stir and dissolve to obtain a yellow polyaluminum chloride solution, place the fully dissolved polyaluminum chloride solution at -10°C for 10 minutes;

[0043] (2) TiCl 4 Add in the polyaluminium chloride solution gained in step (1), fully stir according to OH - / Al 3+ The molar ratio of the solution is 0.15, and the sodium hydroxide solution with a concentration of 1mol / L is added dropwise. After the dropwise addition, the constant temperature water bath is continuously stirred for 2 hours to obtain a polytitanium aluminum chloride solution;

[0044] (3) The cationic polyacrylamide is fully stirred and dissolved with water to obtain a colorless transparent viscous solution, and the fully dissolved cationic polyacrylamide solution is stored at a temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com