Preparation method of lithium iron phosphate composite coated by double carbon layers

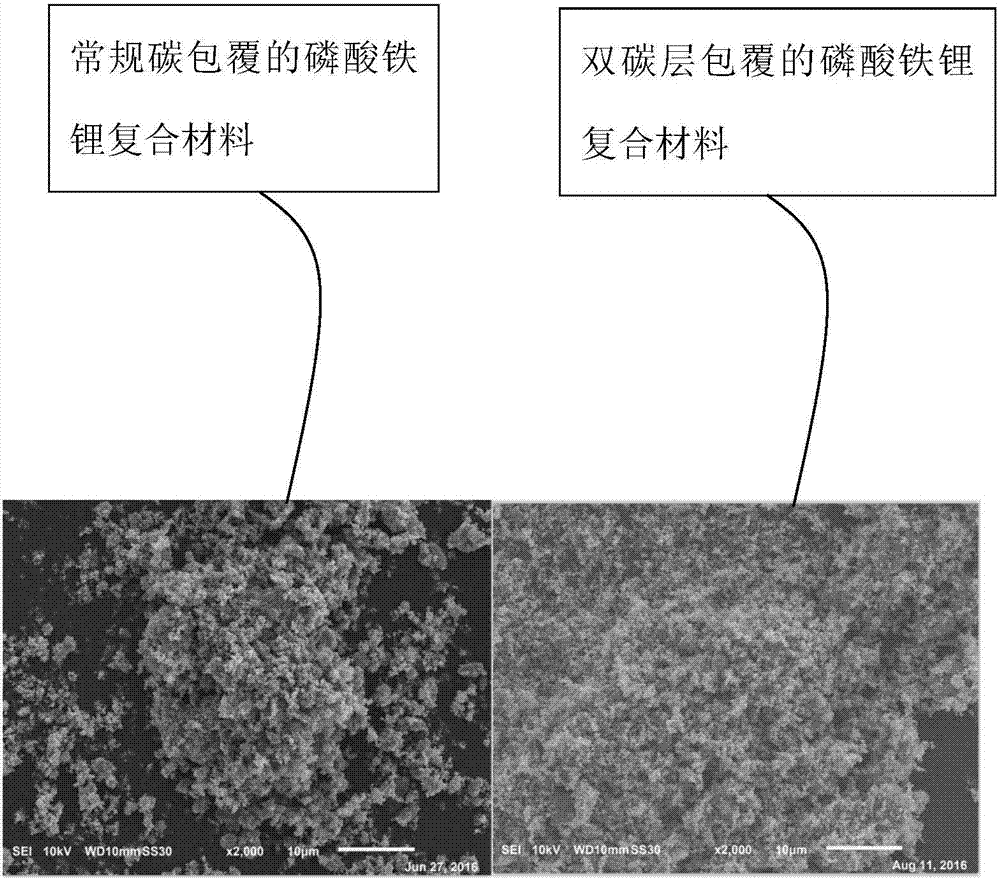

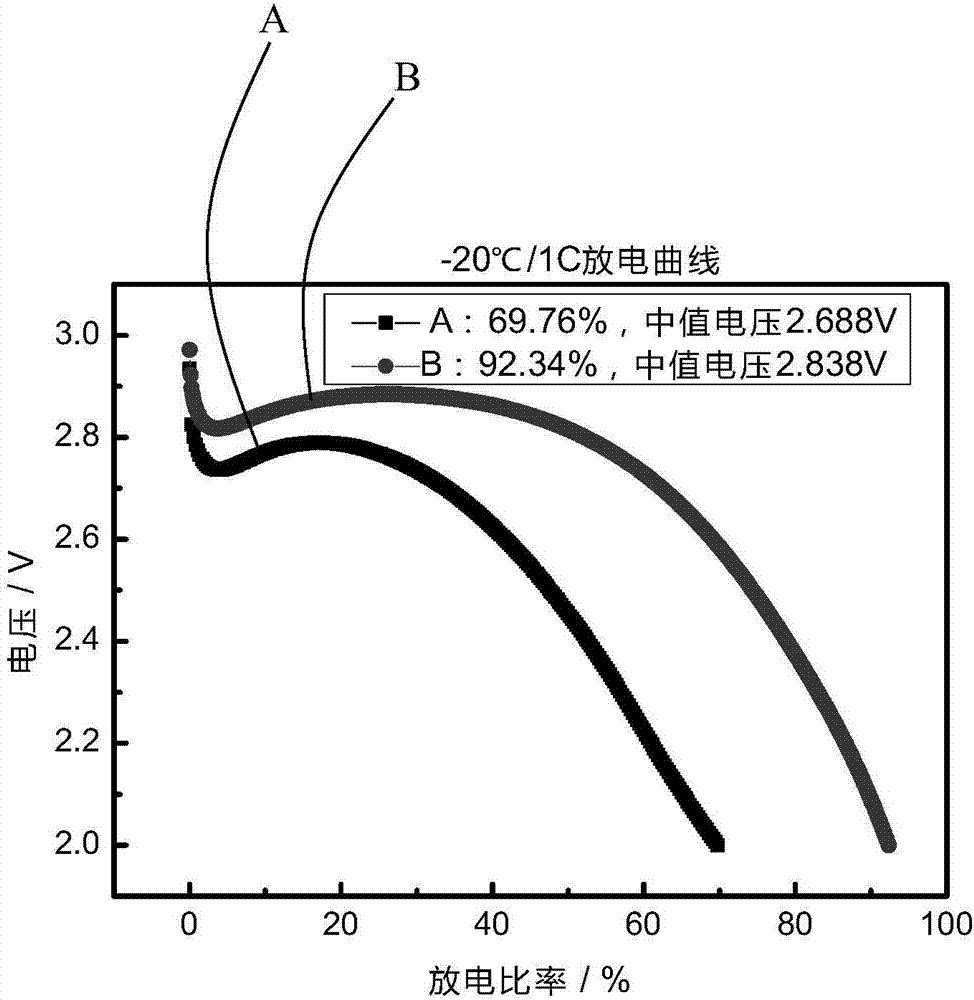

A lithium iron phosphate and composite material technology, applied in lithium batteries, electrical components, battery electrodes, etc., can solve the problems of low carbon content, unsatisfactory electronic conductivity, and difficulties, and achieve small primary particle size, charging and discharging. Excellent cycle performance and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing a lithium iron phosphate composite material coated with a double carbon layer, comprising the following steps:

[0026] step one:

[0027] First mix the iron source, phosphorus source and lithium source with a molar ratio of 1-2:0.5-1.3:1.9-3.9 and dissolve them in the ethanol solution to form a mixed solution, in which the iron source, phosphorus source and lithium source respectively account for The mass ratio of the ethanol solution is 8%-10%, 5%-8% and 20%-35%, and then adding a carbon source accounting for 1%-3.5% of the mass ratio of the ethanol solution is dissolved in the mixed solution to form the first mixture , and then adding ordered mesoporous carbon accounting for 2%-5% of the mass ratio of the ethanol solution to the first mixture, and ultrasonically treating at room temperature for a first preset time to form a second mixture;

[0028] Step two:

[0029] The second mixture in step 1 is first placed in a con...

Embodiment

[0040] Step 1: first mix ferrous sulfate, diammonium hydrogen phosphate and lithium hydroxide with a molar ratio of 1:1:3 and dissolve them in the ethanol solution to form a mixed solution, in which the iron source, phosphorus source and lithium source respectively occupy the ethanol solution The mass ratio is 10%, 8% and 35%, then add 3% glucose which accounts for the mass ratio of ethanol solution and dissolve it in the mixed solution to form the first mixture, then add 2% of the orderly which accounts for the mass ratio of ethanol solution The mesoporous carbon was added to the first mixture and sonicated for 30 min at room temperature to form the second mixture.

[0041] Step 2: first place the second mixture in step 1 in a container, conduct a hydrothermal reaction at 130°C for 8 hours, then cool to room temperature to form a third mixture, and then wash and dry the third mixture to obtain a carbon-doped Lithium iron phosphate composite material.

[0042] Step 3: first p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com