Preparation method for quasi-vertical-structured GaN-based schottky diode

A Schottky diode, vertical structure technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., to reduce expansion resistance, solve current crowding, and small ohmic contact distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

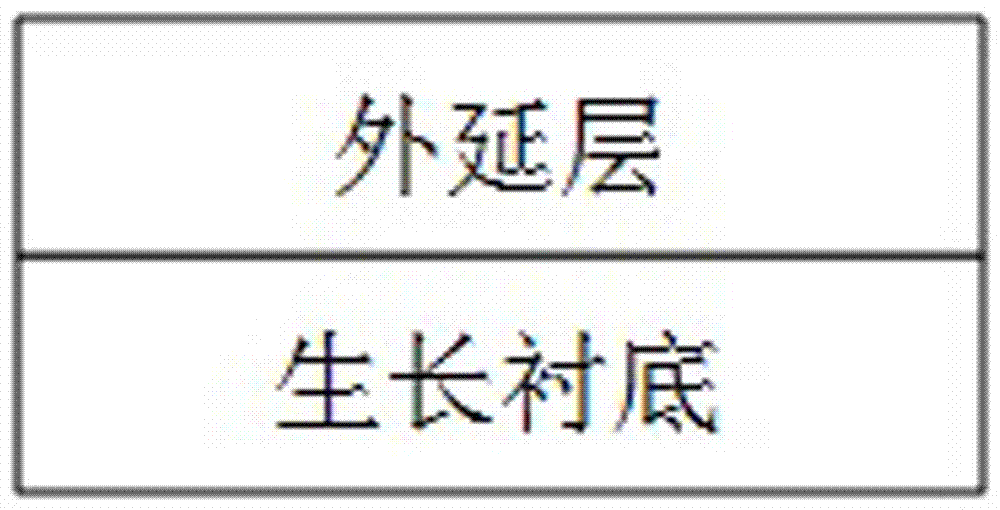

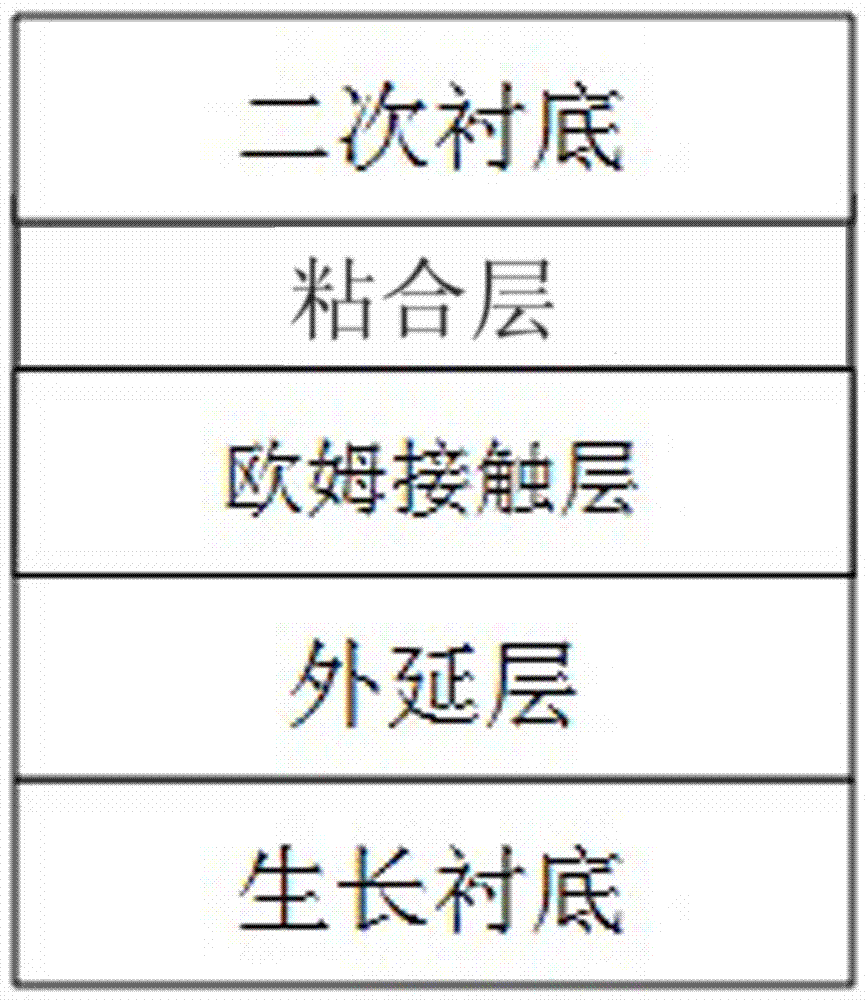

[0023] For the preparation method of the GaN-based Schottky diode with quasi-vertical structure provided by the present invention, please refer to Figure 1-Figure 5 , epitaxially growing a highly doped N-type GaN layer on the growth substrate; epitaxially growing a highly doped N+ GaN layer on the N-type GaN layer; making an ohmic contact on the N+ GaN layer, such as figure 2 As shown; Schottky contacts are formed on the N-layer, and the Schottky contacts are introduced to the anode through an air bridge, such as Figure 5 shown.

[0024] The technical solution further adopted by the present invention is that the doping elements of the highly doped N-type GaN layer epitaxially grown on the growth substrate are group IV elements, and the doping concentration is 10 16 / cm 3 magnitude to 10 19 / cm 3 Between magnitudes; the doping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com