Method for testing food additives in foods by virtue of high performance liquid chromatography

A technology of high performance liquid chromatography and food additives, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of easy interference of components, inaccurate measurement results, overlapping of chromatographic peaks, etc., to eliminate interference of other components, Improve detection efficiency and reduce interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

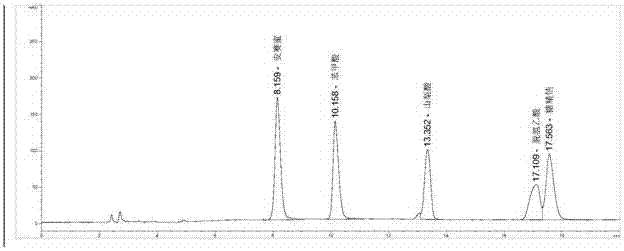

[0036] The present embodiment provides a method for testing food additives in food by high performance liquid chromatography, comprising the following steps:

[0037] 1) Preparation of standard series of working solutions: Weigh the standard substances acesulfame potassium, sodium saccharin, benzoic acid, sorbic acid, dehydroacetic acid 0.1g (accurate to 0.00001g), transfer to a 100mL volumetric flask, add 20mL methanol to dissolve, Add water to make up to the mark; add water to the above mixed standard solution and dilute step by step to obtain a mixed standard series working solution of 5 additives, the concentrations are 1.0μg / mL, 5.0μg / mL, 10.0μg / mL, 20.0μg / mL , 100.0 μg / mL.

[0038] 2) Preparation of test solution:

[0039]The first step is to take a commercially available jelly as a sample, weigh 2g of the sample (accurate to 0.0001g), add 10mL of water to dilute, heat to 70°C to dissolve it, and then transfer the dissolved sample to a 50mL stoppered centrifuge tube Ad...

Embodiment 2

[0054] The present embodiment provides a method for testing food additives in food by high performance liquid chromatography, comprising the following steps:

[0055] 1) Preparation of standard series of working solutions: Weigh the standard substances acesulfame potassium, sodium saccharin, benzoic acid, sorbic acid, dehydroacetic acid 0.1g (accurate to 0.00001g), transfer to a 100mL volumetric flask, add 20mL methanol to dissolve, Add water to make up to the mark; add water to the obtained mixed standard solution and dilute step by step to obtain a mixed standard series working solution of 5 additives, the concentrations are 1.0μg / mL, 5.0μg / mL, 10.0μg / mL, 20.0μg / mL mL, 100.0 μg / mL.

[0056] 2) Preparation of test solution:

[0057] The first step is to take a commercially available cake as a sample, weigh 2g of the sample (accurate to 0.0001g), add it to a 50mL centrifuge tube with a stopper, add 25mL of water, vortex and mix, ultrasonically extract for 30min, and then add ...

Embodiment 3

[0068] The present embodiment provides a method for testing food additives in food by high performance liquid chromatography, comprising the following steps:

[0069] 1) Preparation of standard series of working solutions: Weigh the standard substances acesulfame potassium, sodium saccharin, benzoic acid, sorbic acid, dehydroacetic acid 0.1g (accurate to 0.00001g), transfer to a 100mL volumetric flask, add 20mL of methanol to dissolve, Add water to make up to the mark; add water to the obtained mixed standard solution and dilute step by step to obtain a mixed standard series working solution of 5 additives, the concentrations are 1.0μg / mL, 5.0μg / mL, 10.0μg / mL, 20.0μg / mL , 100.0 μg / mL.

[0070] 2) Preparation of test solution:

[0071] The first step is to take a commercially available sausage as a sample, weigh 2g of the sample (accurate to 0.0001g), add the sample to 10mL of n-hexane, then heat it in a water bath at 60°C for 5min, and add 1% of the sausage after the fat is d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com