A kind of preparation method of inkjet printing high penetration reactive dye ink

A technology of reactive dyes and inkjet printing, used in dyeing, ink, textiles and papermaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

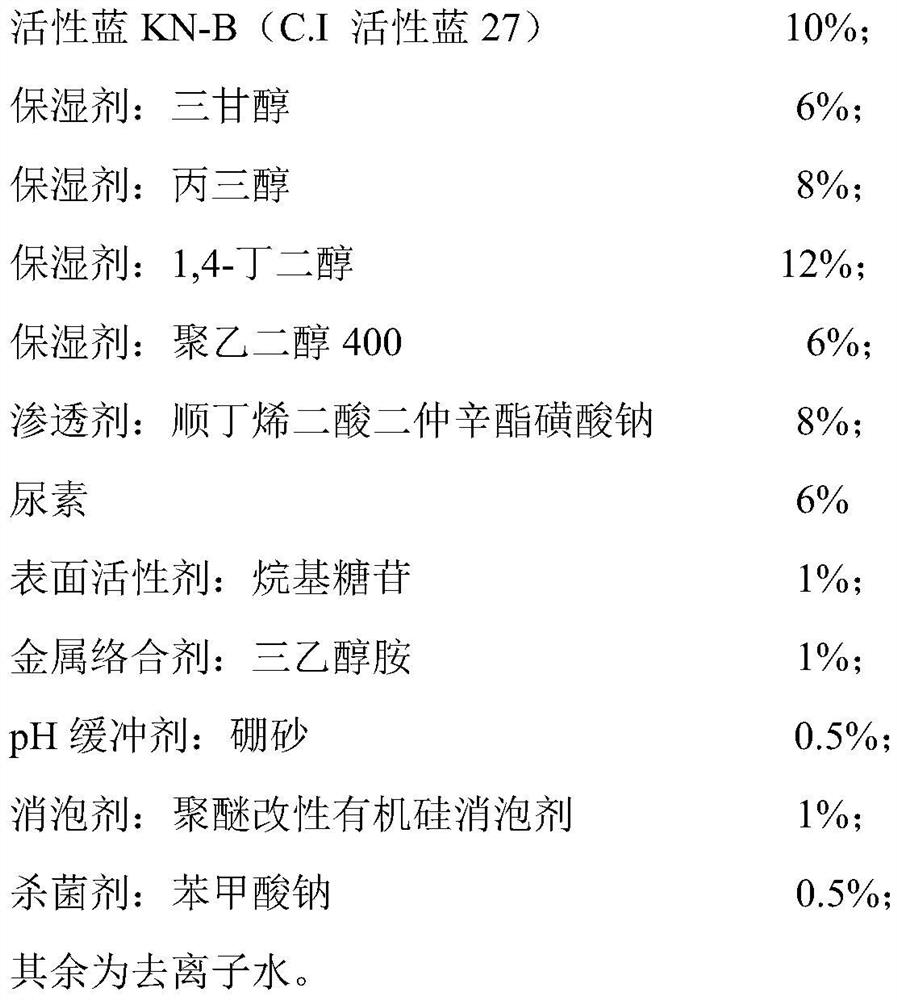

[0023]Preparation of active red ink:

[0024]

[0025]The above substance was sequentially added to the flask, mixed and stirred and uniform, and then used in sequentially filtered by 1.5 microns, 0.52 microns, 0.2 microns, and prepared high permeable ink printing active red ink.

[0026]The preparative ink is printed in the printing fluidity test, and there is no disconnection closure within 24 hours, and the fluency is good. Prepared ink to silk fabric (100 g / m2), Inkjet printing (printing 5 × 5 cm pure-color block), 102 ° C steamed solid color 20 minutes, cold water washing, hot water washing, cold water washing, test print fabric color deep value (K / S colorimeter, fabric Folding double layer), printed front K / S value: 13.6, reverse surface K / S value: 12.9, penetration is 94.85% (permeability = fabric reverse surface K / S value / fabric front K / S value), strong loss rate is 2%, good penetration, and negative printed effects can be achieved.

[0027]After testing the printing, the ...

Embodiment 2

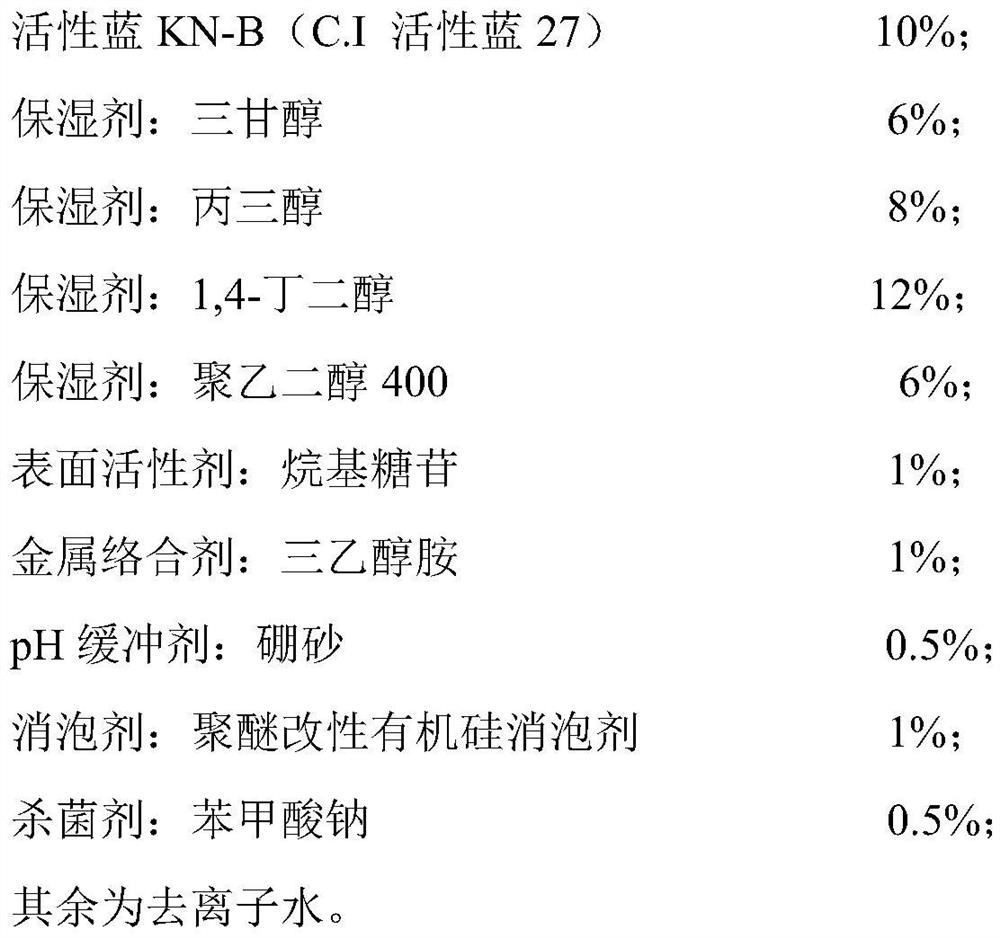

[0029]Preparation of active blue ink:

[0030]

[0031]The above substance was added to the flask, mixed and stirred and uniform, then in turn by 1.5 microns, 0.52 microns, 0.2 microns filtration, and prepared high permeable ink printing active blue ink.

[0032]The preparative ink is printed in the printing fluidity test, and there is no disconnection closure within 24 hours, and the fluency is good. Prepared ink to silk fabric (100 g / m2), Inkjet printing (printing 5 × 5 cm pure-color block), 102 ° C steamed solid color 20 minutes, cold water washing, hot water washing, cold water washing, test print fabric color deep value (K / S colorimeter, fabric Folding double layer), print front K / S value: 12.2, reverse surface K / S value 11.7, penetration is 95.90% (permeability = fabric reverse surface K / S value / fabric front K / S), strong loss rate is 2 The% infiltration effect is good, and there is a good printing effect. After testing the printing, the water washed with the fabric was 4-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com