Long-lived flat fiber-modified polyamide composites for laser welding

A flat fiber, laser welding technology, applied in the field of modified polymer composite materials, can solve the problems of reducing the service life of welded products, attenuation of welding strength, performance attenuation, etc., to achieve the effect of promoting absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

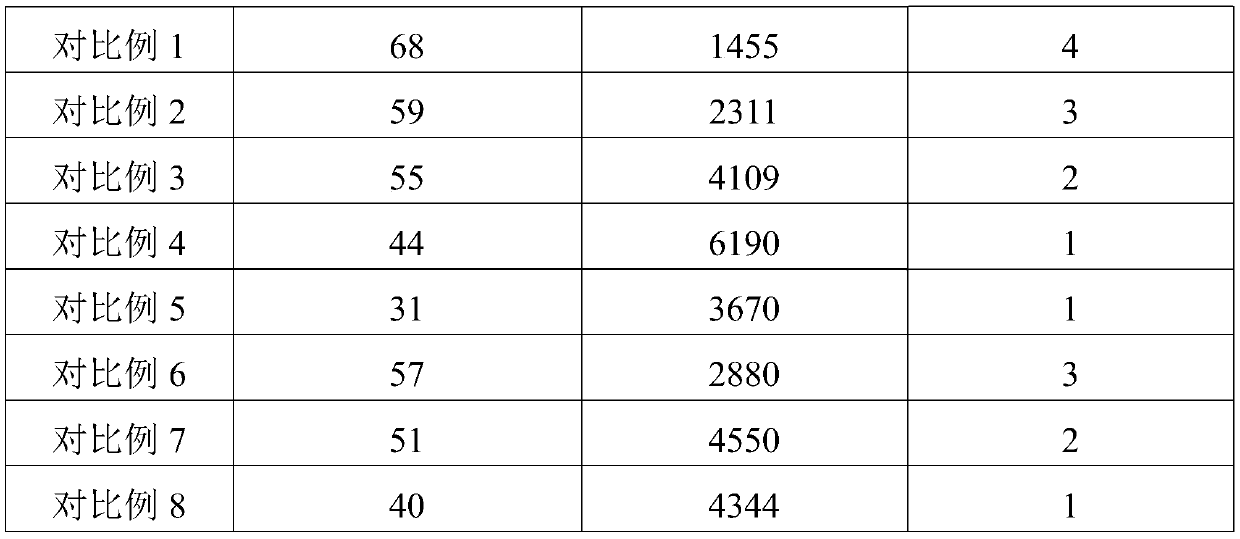

Examples

specific Embodiment 1

[0038] Laser absorption part: 90 parts of PA66, 5 parts of copper hydroxide phosphate, 0.05 part of cuprous iodide, 1 part of sodium bromide;

[0039] Transmission laser part: 90 parts of PA66, 2 parts of Sb 2 o 3 , 0.5 parts of titanium dioxide FRC5, 0.05 parts of cuprous iodide, 1 part of sodium bromide.

specific Embodiment 2

[0041] Laser absorption part: 70 parts of PA66, 2 parts of copper phosphate, 0.5 parts of copper bromide, 2 parts of potassium iodide, 10 parts of ECS301CL, 10 parts of CSG3PA-820;

[0042] Transmission laser part: 70 parts of PA66, 1.0 parts of titanium dioxide R930, 0.5 parts of copper bromide, 2 parts of potassium iodide, 10 parts of ECS301CL, 10 parts of CSG3PA-820.

specific Embodiment 3

[0044] Laser absorption part: 60 parts of PA66, 1 part of sodium phosphate, 2 parts of cuprous iodide, 5 parts of sodium bromide, 10 parts of ECS301CL, 20 parts of CSG3PA-820;

[0045] Transmission laser part: 60 parts of PA66, 0.01 parts of titanium dioxide CR834, 2 parts of cuprous iodide, 5 parts of sodium bromide, 10 parts of ECS301CL, 20 parts of CSG3PA-820.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com