NiFe3N/NF electrochemical catalyst and preparation method and application thereof

A catalyst and electrochemical technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of poor electron conductivity of Ni-based catalysts, inability to large-scale production, and scarcity of crustal content, etc. problem, to achieve the effect of low cost of raw materials, easy operation, and improved oxygen evolution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Acid pretreatment: Prepare a hydrochloric acid solution with a concentration of 3 M, pour it into a single-necked round bottom flask, and put it in an oil bath; cut the foam nickel into a size of 1×2 cm, clean it with deionized water, and put it in a container. In a flask containing hydrochloric acid, heat to 90°C for 30 minutes, then cool to room temperature and wash with water;

[0046] (2) Surface oxidation treatment: The nickel foam after hydrochloric acid pretreatment is oxidized in the air for 2 days to keep it in a wet state at a temperature of 30°C and an air humidity of 85%.

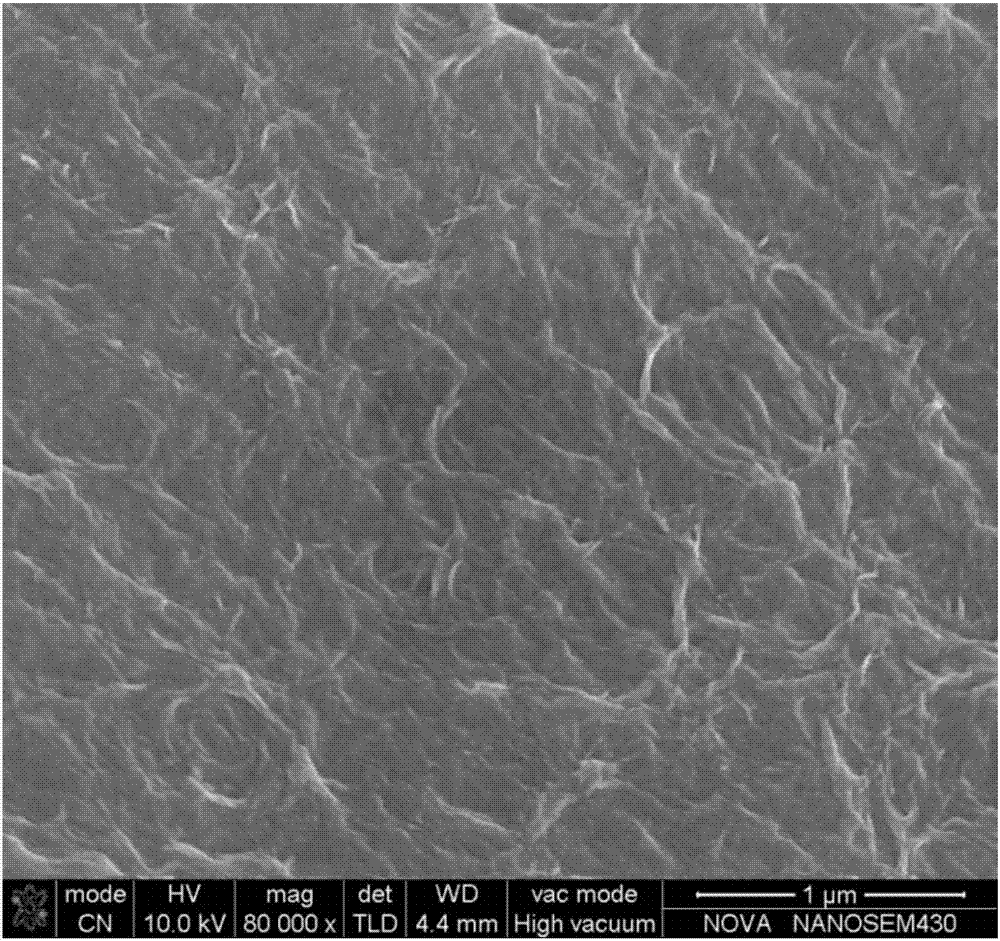

[0047] The morphology of nickel oxide formed on the foamed nickel after surface oxidation treatment is as follows: figure 1 shown by figure 1 It can be seen that a thin layer of nickel oxide layer that grows uniformly is formed on the surface of the foamed nickel sheet.

Embodiment 2

[0049] (1) Prepare a hydrochloric acid solution with a concentration of 3 M, pour it into a single-necked round-bottomed flask, put it into an oil bath, cut the nickel foam into a size of 1×2 cm, clean it with deionized water, and put it into a flask filled with hydrochloric acid. In the flask, heat to 90°C for 30 minutes, then cool to room temperature and clean with water; the nickel foam is oxidized in the air for 2 days to keep it in a wet state, the temperature is 30°C, and the air humidity is 85%;

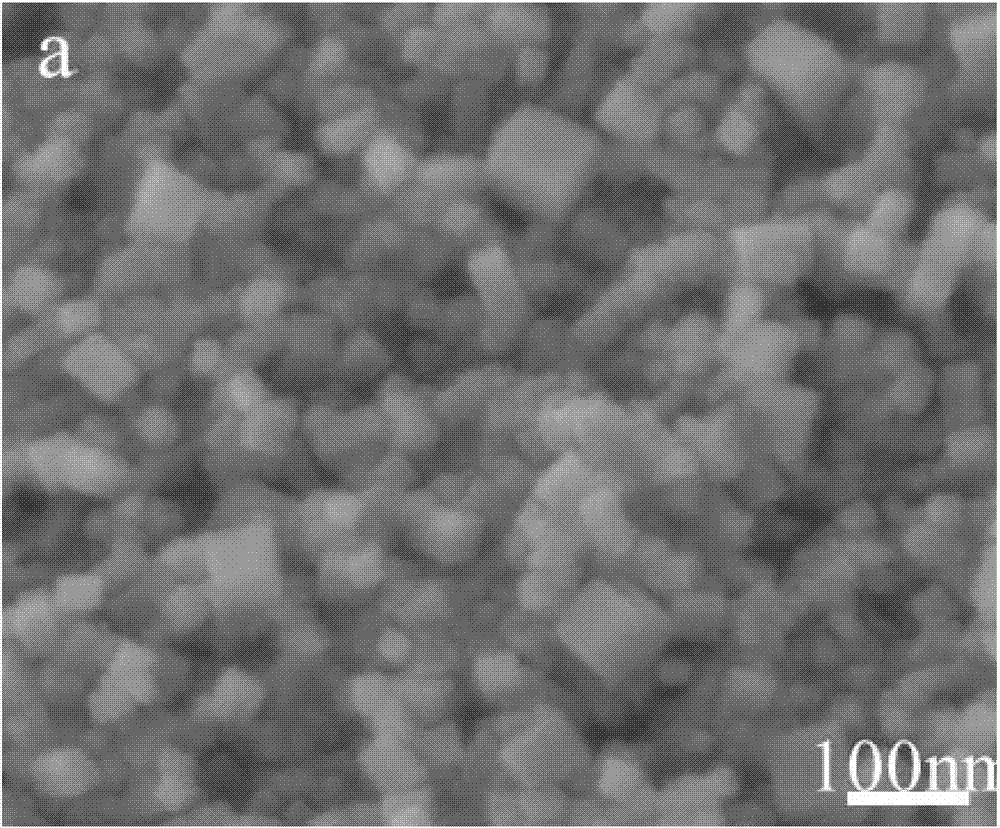

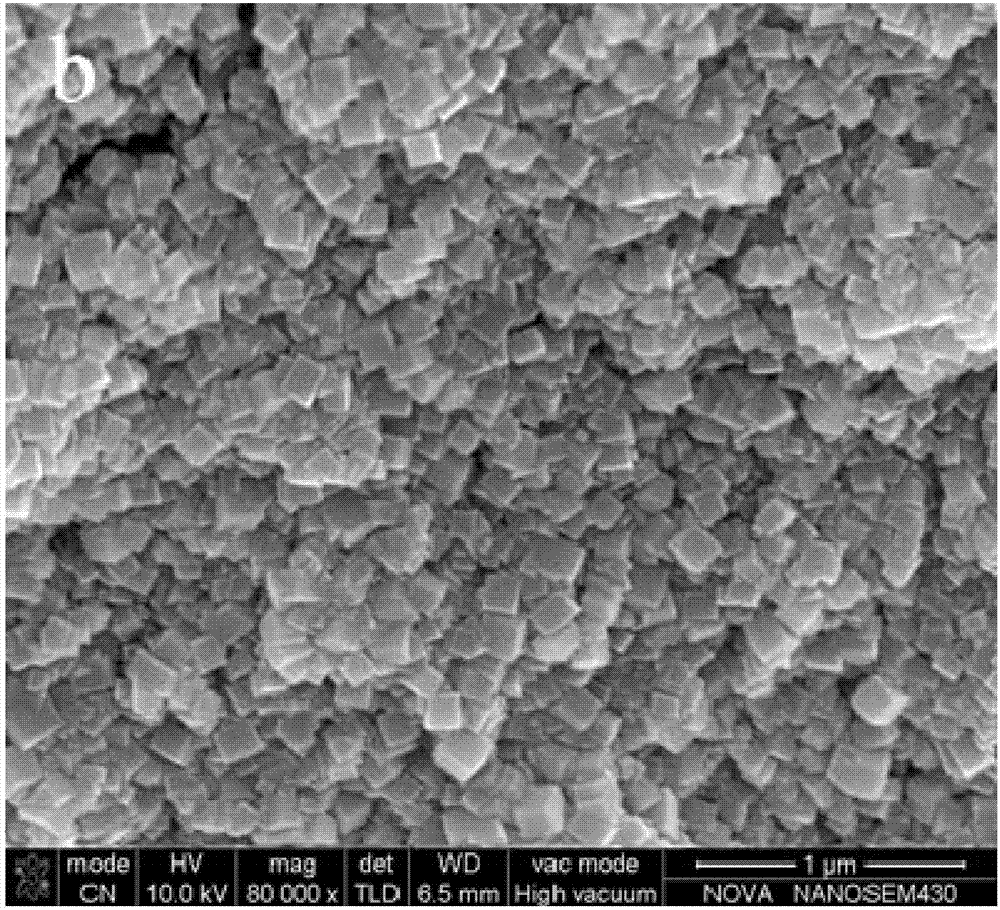

[0050] (2) Prepare 20 mL of K with a concentration of 0.02 mol / L 4 Fe(CN) 6 Solution, immerse a piece of 1×2cm surface oxidized nickel foam in K 4 Fe(CN) 6 In the solution, add 0.015mol / L trisodium citrate, and use the nickel oxide on the surface of the nickel foam as the nickel source to make the ligand K 4 Fe(CN) 6 The Fe source in the mixture was combined with the nickel source, and the MOF material (NiFe-PBA / NF) was obtained by standing at room temperature for 6h, 12h,...

Embodiment 3

[0053] (1) Prepare a hydrochloric acid solution with a concentration of 3 M, pour it into a single-necked round-bottomed flask, put it into an oil bath, cut the nickel foam into a size of 1×2 cm, clean it with deionized water, and put it into a flask filled with hydrochloric acid. In the flask, heat to 90°C for 30 minutes, then cool to room temperature and clean with water; the nickel foam is oxidized in the air for 2 days to keep it in a wet state, the temperature is 30°C, and the air humidity is 85%;

[0054] (2) Prepare 20mL of K with concentrations of 0.01mol / L, 0.015mol / L, and 0.02mol / L 4 Fe(CN) 6 Solution, immerse a piece of 1×2cm surface oxidized nickel foam in K 4 Fe(CN) 6 In the solution, add the trisodium citrate of 0.015mol / L, take the nickel oxide on the surface of the nickel foam as the nickel source to make the ligand K 4 Fe(CN) 6 The Fe source and the nickel source in the mixture were combined, and the MOF material (NiFe-PBA / NF) was obtained by standing at r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com