Preparation method of through-hole dual-network polymeric hydrogel scaffold

A polymer, dual network technology, applied in the fields of medical science, prosthesis, tissue regeneration, etc., can solve problems such as limited application, and achieve the effect of avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

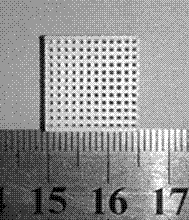

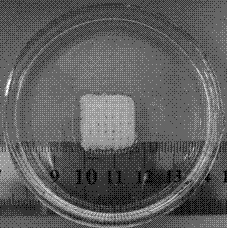

[0028] In step A) of the present invention, use fused deposition modeling (FDM) additive manufacturing printer and polylactic acid as consumables to manufacture such as figure 1 A polylactic acid porous scaffold template with a pore size of 500 microns and through holes;

[0029] Step B), 9.8 grams of water, 0.2 grams of sodium alginate and 0.01 grams of glutaraldehyde are mixed and poured into the porous template, and then placed in a low-temperature freeze dryer to dry to obtain the porous scaffold template / single network polymer preform SN ;

[0030] Step C), mix 1.0 g of water, 0.5 g of acrylamide monomer, 0.05 g of N,N-methylene-bisacrylamide crosslinker, 0.01 g of ammonium persulfate, and 0.01 g of tetramethylethylenediamine and perfuse Enter the porous scaffold template / single network polymer preform SN, and then place it in a nitrogen environment with a temperature of 50°C and a humidity of 90% for 12 hours to obtain the porous scaffold template / double network polymer...

Embodiment 2

[0033] ABS was used as the printing consumable, and other preparation conditions were the same as in Example 1 to obtain an alginic acid-polyacrylamide double network polymer hydrogel scaffold with a pore diameter of 500 microns and through pores.

Embodiment 3

[0035] In step A), a porous polylactic acid scaffold with a pore diameter of 10 microns was printed, and the other preparation conditions were the same as in Example 1 to obtain an alginic acid-polyacrylamide double network polymer hydrogel with a pore diameter of 10 microns and through pores stand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com