A kind of high rate porous carbon electrode material for supercapacitor and its preparation method

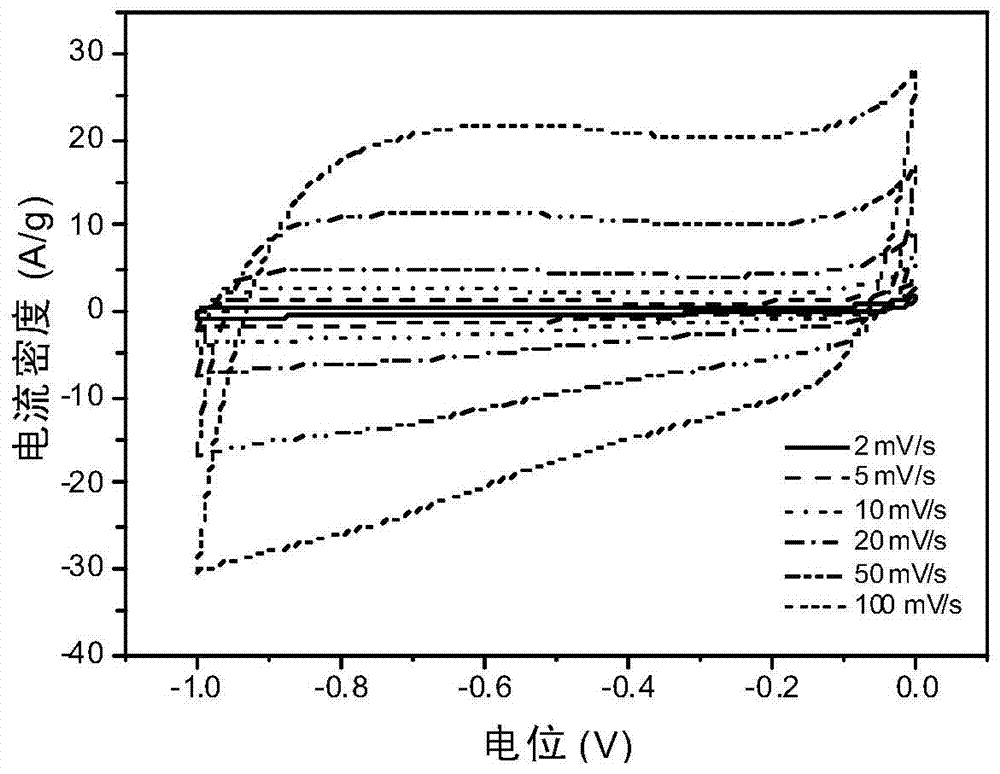

A technology for supercapacitors and carbon electrodes, which is applied in the fields of hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, carbon preparation/purification, etc. Capacitor electrode materials and other issues, to achieve the effect of high specific surface area and excellent rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 2.23g Zn(NO 3 ) 2 ·6H 2 O, 0.12g Co(NO 3 ) 2 ·6H 2 O and 0.6g of 2-methylimidazole were dissolved in 180ml of N,N-dimethylformamide. Then the mixed solution was placed in a hydrothermal kettle, and hydrothermally treated at 140° C. for 24 h. The hydrothermal product was washed with N,N-dimethylformamide solution for more than 3 times, and then the product was dried in an oven at 60°C. The dried product was carbonized at 800 °C for 3 h in a nitrogen atmosphere. The obtained carbonized product was treated with potassium hydroxide solution, and then the treated sample was washed with deionized water until neutral. After the above product was treated with hydrochloric acid solution, it was washed with deionized water until neutral. The cleaned product was dried in an oven at 60° C. for 24 hours to obtain hierarchical porous carbon.

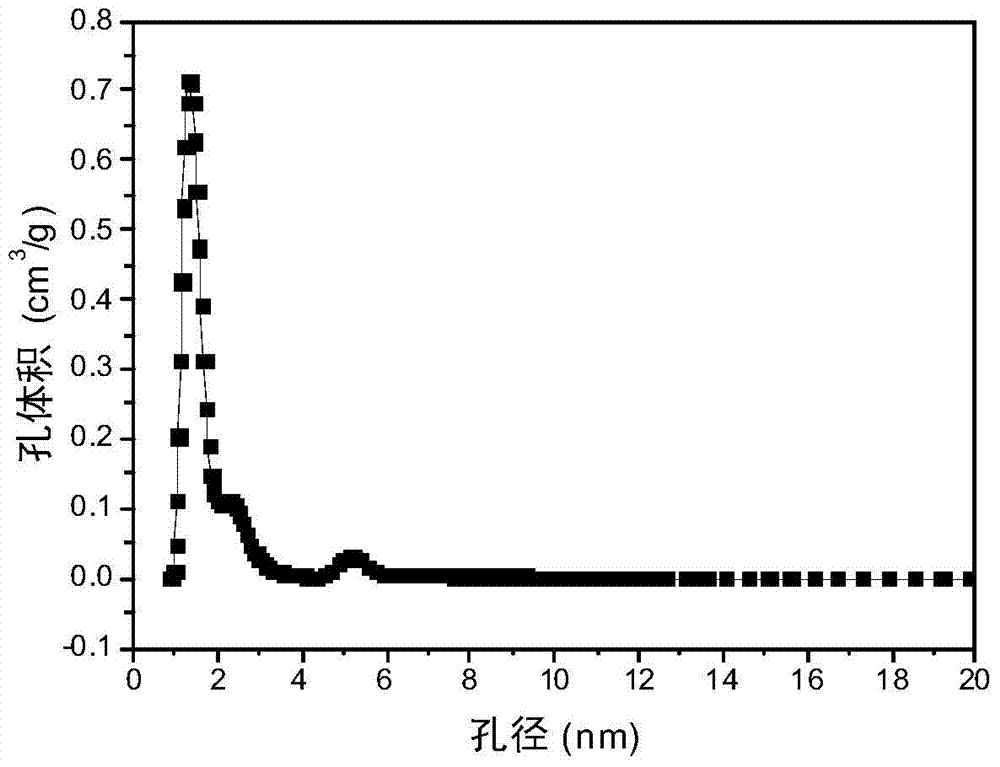

[0028] Physical adsorption tests show that the carbon material presents a concentrated pore size distribution at 1.3nm and 5.1nm (suc...

Embodiment 2

[0030] 2.11g Zn(NO 3 ) 2 ·6H 2 O, 0.23g Co(NO 3 ) 2 ·6H 2 O and 0.6g of 2-methylimidazole were dissolved in 180ml of N,N-dimethylformamide, and then the mixed solution was placed in a hydrothermal kettle for hydrothermal treatment at 140°C for 24h. The hydrothermal product was washed with N,N-dimethylformamide solution for more than 3 times, and then the product was dried in an oven at 60°C. The dried product was carbonized at 800° C. for 3 h in a nitrogen atmosphere. After the carbonized product was treated with potassium hydroxide solution, it was washed with deionized water until neutral. Then the obtained sample was treated with hydrochloric acid solution and washed with deionized water. The cleaned samples were dried in an oven at 60° C. for 24 h to obtain hierarchical porous carbon.

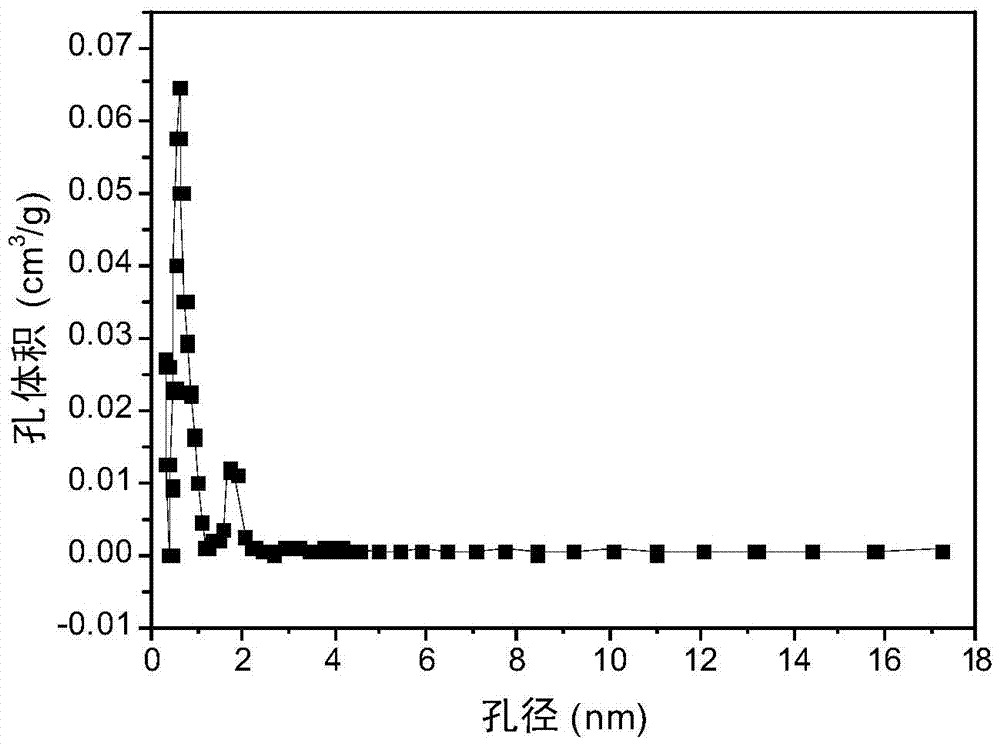

[0031] The physical adsorption results show that the carbon material has a concentrated pore size distribution at 1.2nm and 1.8nm, and the results are as follows image 3 shown. T...

Embodiment 3

[0033] 1.87g Zn(NO 3 ) 2 ·6H 2 O, 0.47g Co(NO 3 ) 2 ·6H 2O and 0.6g of 2-methylimidazole were dissolved in 180ml of N,N-dimethylformamide, and then the mixed solution was placed in a hydrothermal kettle for hydrothermal treatment at 140°C for 24h. The hydrothermal product was washed with N,N-dimethylformamide solution for more than 3 times, and then the product was dried in an oven at 60°C. The dried product was carbonized at 800° C. for 3 h in a nitrogen atmosphere. After the carbonized product was treated with potassium hydroxide solution, it was washed with deionized water until neutral. Then the obtained sample was treated with hydrochloric acid solution and washed with deionized water. The cleaned samples were dried in an oven at 60° C. for 24 h to obtain hierarchical porous carbon.

[0034] The physical adsorption results show that the carbon material has a concentrated pore size distribution at 1.2nm and 5.0nm, and the results are as follows Figure 5 shown. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com