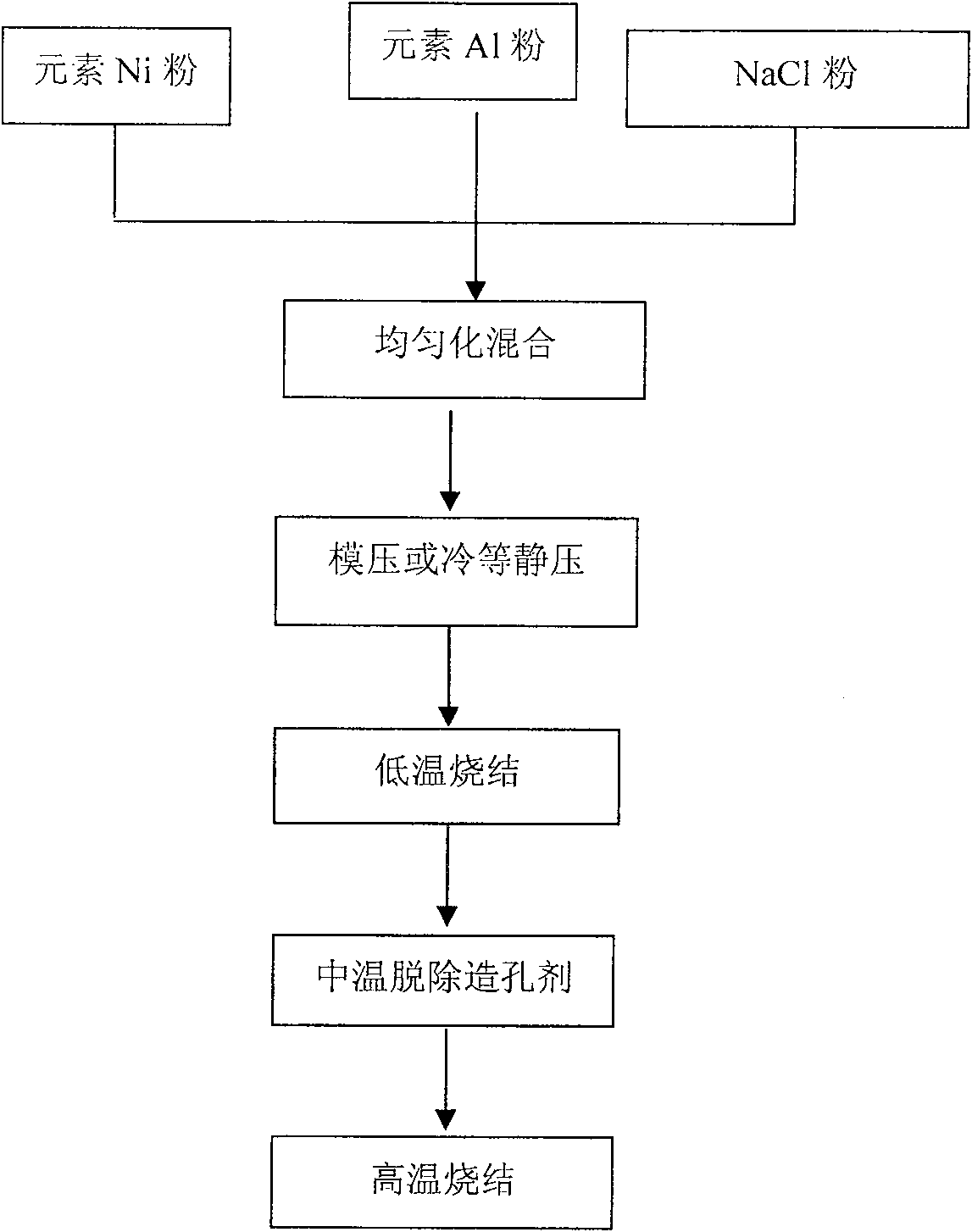

Method of preparing nickel-aluminum base alloy porous material

A porous material, nickel-aluminum-based technology, which is applied in the field of preparation of nickel-aluminum-based alloy porous materials, can solve the problems of uncontrollable pore size, uncontrolled porosity, uneven pore distribution, etc., so as to reduce the preparation cost and the degree of pollution. Small, easy-to-remove effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

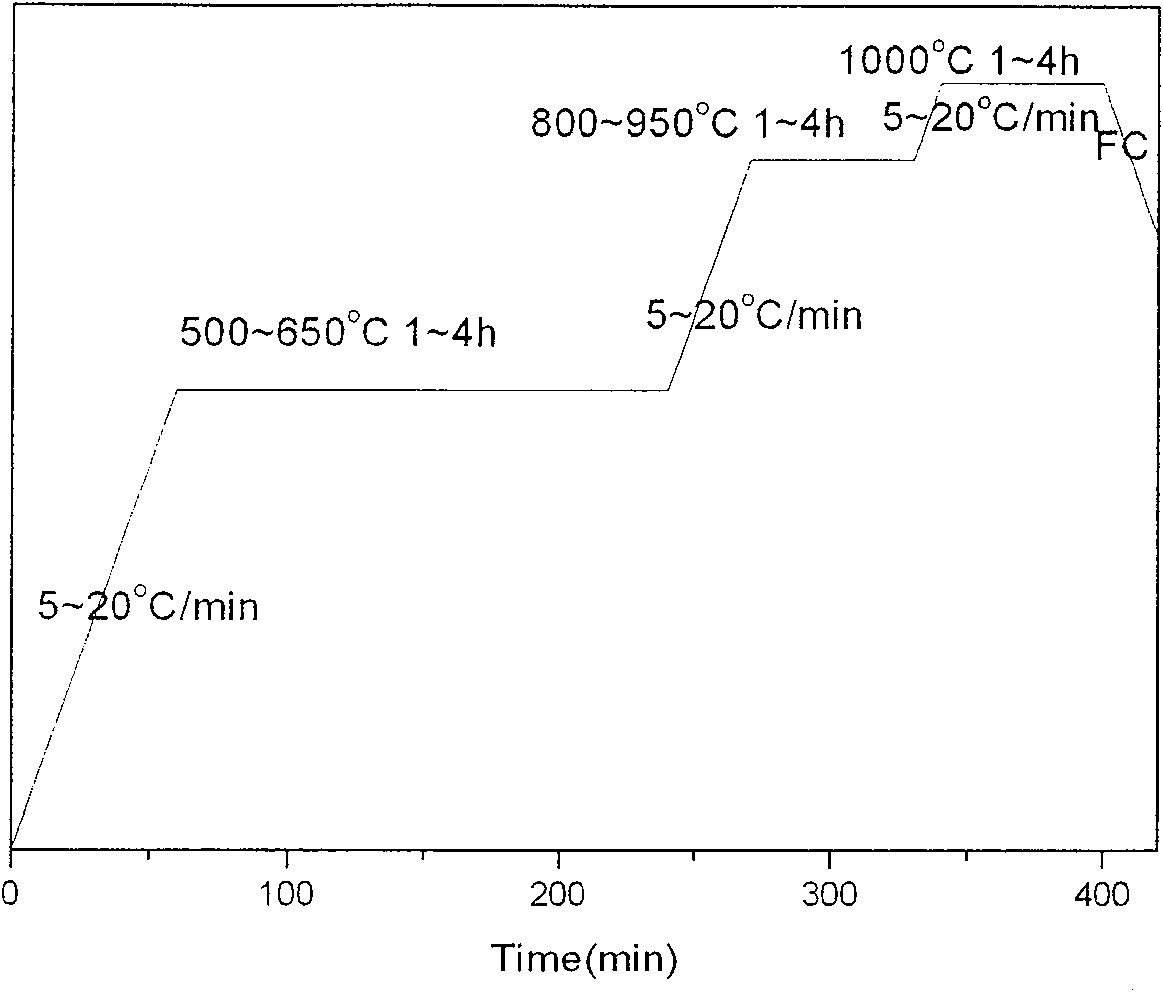

Embodiment 1

[0033] Embodiment 1: Ni powder with a particle size of 1-10 μm, Al powder with a particle size of 10-100 μm and NaCl powder with a particle size of 100-200 μm are used, and Ni:Al:NaCl is proportioned according to the mass ratio of 6.5:1:3. Molding or cold isostatic pressing under a pressure of 500Mpa to make a cold compact with a diameter of d50mm×5mm, then place it in a vacuum sintering furnace, control the vacuum degree to 0.1~10Pa, and raise the temperature at a rate of 5~20°C to Sintering at 500~650°C, holding time: 1~4h, then continue to heat up to 800~950°C at a rate of 5~20°C, hold for 1~4h, and finally, still heat up to 1000°C at a rate of 5~20°C , heat preservation for 1~4h, and then cooled with the furnace to prepare a porous nickel-aluminum-based alloy material with a size of d50mm×5mm and a porosity of 60.5%.

Embodiment 2

[0034] Embodiment 2: Ni powder with a particle size of 1-10 μm, Al powder with a particle size of 10-100 μm and NaCl powder with a particle size of 100-200 μm are used, and Ni:Al:NaCl is proportioned according to the mass ratio of 6.5:1:7.5, Molding or cold isostatic pressing under a pressure of 500Mpa to make a cold compact with a diameter of d50mm×5mm, then place it in a vacuum sintering furnace, control the vacuum degree to 0.1~10Pa, and raise the temperature at a rate of 5~20°C to Sintering at 500~650°C, holding time: 1~4h, then continue to heat up to 800~950°C at a rate of 5~20°C, hold for 1~4h, and finally, still heat up at a rate of 5~20°C to change to 1000°C, heat preservation for 1~4h, and then cool in the furnace to produce a porous nickel-aluminum-based alloy material with a size of d50mm×5mm, and its porosity is 71%.

Embodiment 3

[0035] Embodiment 3: Ni powder with a particle size of 1-10 μm, Al powder with a particle size of 10-100 μm and NaCl powder with a particle size of 100-200 μm are used, and the ratio of Ni:Al:NaCl is 6.5:1:23 by mass, Molding or cold isostatic pressing under a pressure of 500Mpa to make a cold compact with a diameter of d50mm×5mm, then place it in a vacuum sintering furnace, control the vacuum degree to 0.1~10Pa, and raise the temperature at a rate of 5~20°C to Sintering at 500~650°C, holding time: 1~4h, then continue to heat up to 800~950°C at a rate of 5~20°C, hold for 1~4h, and finally, still heat up to 1000°C at a rate of 5~20°C , heat preservation for 1~4h, and then cooled with the furnace to prepare a porous nickel-aluminum-based alloy material with a size of d50mm×5mm and a porosity of 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com