Method for producing chlorinated paraffin-52 by combining thermal chlorination process and photocatalysis process

A chlorinated paraffin and photocatalysis technology, applied in petrochemical modification and other directions, can solve the problems of low chlorine conversion rate, uneven ultraviolet irradiation, uneven chlorine distribution, etc., to shorten the reaction time, heat evenly, and save energy. The effect of energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

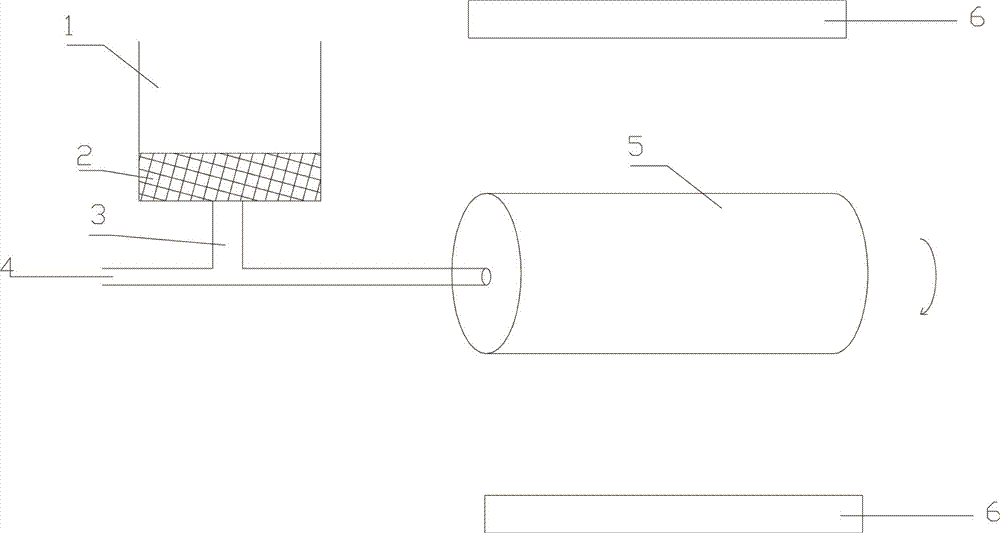

[0030] see figure 1 Shown, a kind of thermal chlorination method combines the method for producing chlorinated paraffin-52 with photocatalytic method, comprises the following steps:

[0031] 1) Prepare a filter screen 2, the filter screen 2 is composed of the following materials in parts by weight: 10 parts of carbon fiber, 20 parts of silica gel, 5 parts of polyurethane resin, and 1 part of seaweed particles;

[0032] 2) Melting the solid paraffin and flowing through the filter screen 2 to obtain refined liquid paraffin;

[0033] 3) the refined liquid paraffin is passed into the reactor 5 added with the catalyst; the catalyst is 0.1% of the solid paraffin weight;

[0034] 4) The reactor 5 is rotated along the horizontal axis, and the refined liquid paraffin and the catalyst are mixed for 10 minutes at a temperature of 80° C.;

[0035] 5) Feed chlorine gas into the position of the horizontal axis where the reactor 5 rotates, keep the reactor rotating along the horizontal axi...

Embodiment 2

[0043] see figure 1 Shown, a kind of thermal chlorination method combines with photocatalytic method to produce the method for chlorinated paraffin-52, comprises the following steps:

[0044] 1) Prepare a filter screen 2, the filter screen 2 is composed of the following materials in parts by weight: 15 parts of carbon fiber, 40 parts of silica gel, 10 parts of polyurethane resin, and 5 parts of seaweed particles;

[0045] 2) Melting the solid paraffin and flowing through the filter screen 2 to obtain refined liquid paraffin;

[0046] 3) said refined liquid paraffin is passed into the reactor 5 that is added with catalyzer; Said catalyzer is 0.2% of solid paraffin weight;

[0047] 4) Rotating the reactor 5 along the horizontal axis, mixing the refined liquid paraffin and the catalyst at a temperature of 100° C. for 10 minutes;

[0048] 5) Feed chlorine gas into the position of the horizontal axis where the reactor 5 rotates, keep the reactor rotating along the horizontal axis...

Embodiment 3

[0056] see figure 1 Shown, a kind of thermal chlorination method combines the method for producing chlorinated paraffin-52 with photocatalytic method, comprises the following steps:

[0057] 1) Prepare a filter screen 2, the filter screen 2 is composed of the following materials in parts by weight: 12 parts of carbon fiber, 30 parts of silica gel, 8 parts of polyurethane resin, and 3 parts of seaweed particles;

[0058] 2) Melting the solid paraffin and flowing through the filter screen 2 to obtain refined liquid paraffin;

[0059] 3) said refined liquid paraffin is passed into the reactor 5 that is added with catalyzer; Said catalyzer is 0.2% of solid paraffin weight;

[0060] 4) The reactor 5 is rotated along the horizontal axis, and the refined liquid paraffin and the catalyst are mixed for 8 minutes at a temperature of 90° C.;

[0061] 5) Feed chlorine gas into the position of the horizontal axis where the reactor 5 rotates, keep the reactor rotating along the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com