Water-soluble high-efficiency high-strength putty paint and preparation method thereof

A water-soluble and high-efficiency technology, applied in the field of putty paint, can solve the problems of difficult construction of putty powder and poor performance of putty powder, and achieve the effects of rich hand feeling, good wear resistance and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

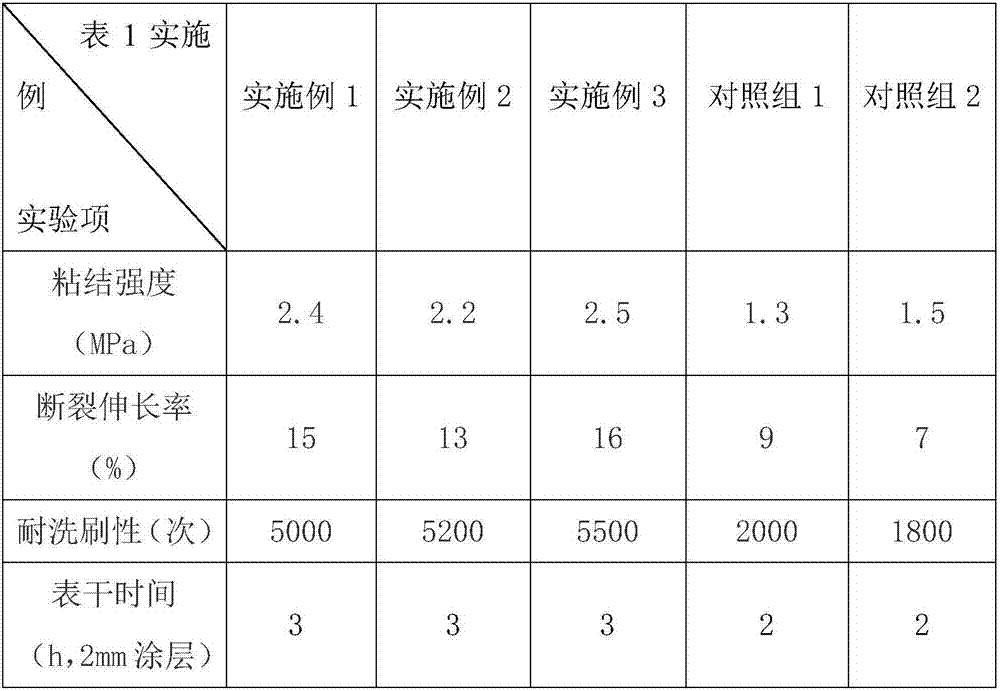

Examples

Embodiment 1

[0026] A water-soluble high-efficiency high-strength putty paint, prepared from the following raw materials in parts by mass: 55 parts of quartz powder, 40 parts of titanium dioxide, 25 parts of modified gypsum powder, 15 parts of expanded perlite, 12 parts of filler, 5 parts of cellulose 6 parts, 6 parts of additives and 60 parts of deionized water;

[0027] Wherein, the modified gypsum powder includes the following raw materials in parts by weight: 50 parts of gypsum powder, 25 parts of 25% stearic acid and 15 parts of absolute ethanol; the preparation method is to weigh the gypsum powder and add it to stearin acid-dehydrated ethanol mixed solution, mix evenly to obtain a suspension, filter, dry the filter cake at 70°C, and grind finely to obtain modified gypsum powder;

[0028] Wherein, the auxiliary agent includes the following raw materials in parts by weight: 5 parts of penetrating agent, 4 parts of dispersing agent, 0.4 part of defoamer, 6 parts of film-forming auxiliar...

Embodiment 2

[0040] A water-soluble high-efficiency high-strength putty paint, prepared from the following raw materials in parts by mass: 50 parts of quartz powder, 30 parts of titanium dioxide, 20 parts of modified gypsum powder, 10 parts of expanded perlite, 8 parts of filler, 2 parts of cellulose -8 parts, 2 parts of additives and 50 parts of deionized water;

[0041] Wherein, the modified gypsum powder includes the following raw materials in parts by weight: 40 parts of gypsum powder, 15 parts of 20% stearic acid and 10 parts of absolute ethanol; the preparation method is to weigh the gypsum powder and add it to stearin acid-dehydrated ethanol mixed solution, mix evenly to obtain a suspension, filter, dry the filter cake at 60°C, and grind finely to obtain modified gypsum powder;

[0042] Wherein, the auxiliary agent includes the following raw materials in parts by weight: 3 parts of penetrating agent, 2 parts of dispersing agent, 0.2 part of defoamer, 4 parts of film-forming auxiliar...

Embodiment 3

[0054] A water-soluble high-efficiency high-strength putty paint, prepared from the following raw materials in parts by mass: 60 parts of quartz powder, 50 parts of titanium dioxide, 30 parts of modified gypsum powder, 20 parts of expanded perlite, 15 parts of filler, 8 parts of cellulose parts, 10 parts of additives and 70 parts of deionized water;

[0055] Wherein, the modified gypsum powder includes the following raw materials in parts by weight: 60 parts of gypsum powder, 35 parts of 30% stearic acid and 20 parts of absolute ethanol; the preparation method is to weigh the gypsum powder and add it to stearin acid-dehydrated ethanol mixed solution, mix evenly to obtain a suspension, filter, dry the filter cake at 80°C, and grind finely to obtain modified gypsum powder;

[0056] Wherein, the auxiliary agent includes the following raw materials in parts by weight: 8 parts of penetrating agent, 6 parts of dispersant, 0.6 part of defoamer, 8 parts of film-forming auxiliary agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com