Viscose acrylic fiber home textile fabric and preparation method thereof

A technology of acrylic fiber and viscose, which is applied in the field of its preparation, can solve the problems of wide fabric width, high actual cost, dyeing color, etc., and achieve the effect of small color difference between head and tail, uniform color, and short and dense fluff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

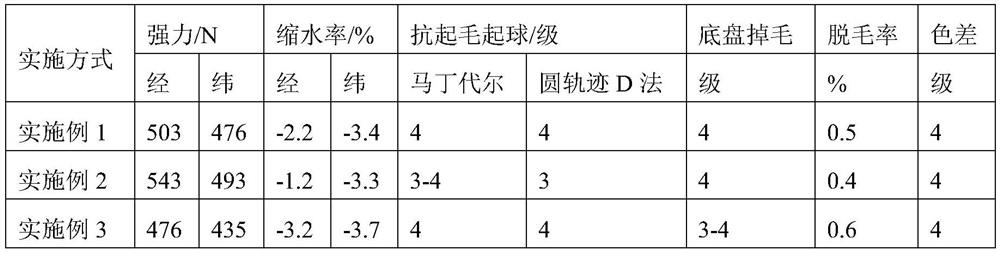

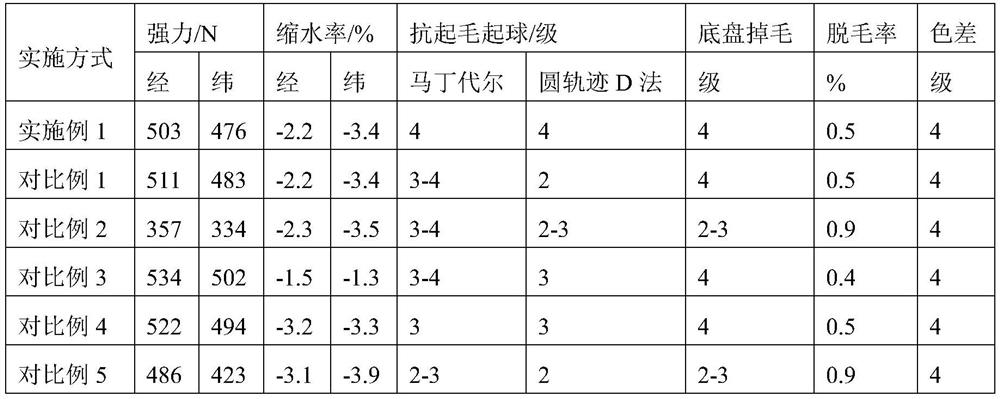

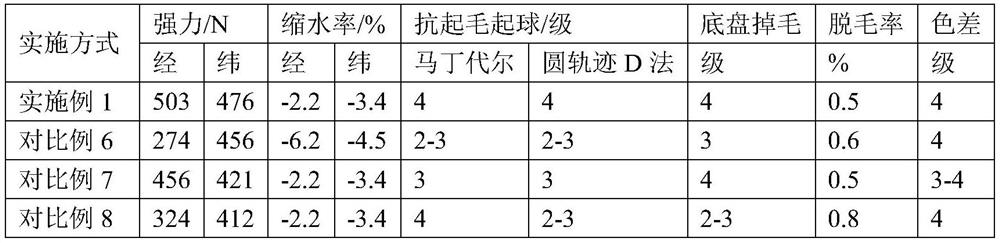

Examples

Embodiment 1

[0028] 106” / 40s×40s / 160×95, 4 / 1 satin, viscose: acrylic = 70:30, yarn twist 105 twists / 10cm.

[0029] 1. Pretreatment process

[0030] Singeing: one front and one reverse light singeing, the speed is 115m / min.

[0031] Desizing: Desizing with amylase, the dosage of α-amylase is 8g / L, the dosage of non-ionic penetrant is 1.5g / L, keep warm at 50-60℃ for 4-6h, and then wash with 5 grids of hot water at 70-80℃ , working solution pH5-6.

[0032] Bleaching: 100% hydrogen peroxide 1.5g / L, hydrogen peroxide stabilizer 1.5g / L, chelating dispersant 2.5g / L, heat preservation at 95-98°C for 60min, working solution pH 8-9.

[0033] Light sanding: The fabric is sanded in sequence, then ceramic sanded, and finally the cloth is produced. Among them, the cloth inlet tension is 9kg, the cloth outlet tension is 12kg, 2 rollers for sanding, 6 rollers for ceramics, the speed of sanding rollers is 1000r / min, the mesh number of sanding is 600 mesh, the speed of ceramic rollers is 1050r / min, and t...

Embodiment 2

[0042] 106” / 40s×40s / 160×95, 4 / 1 satin, viscose: acrylic = 60:40, yarn twist 110 twists / 10cm, siro compact spinning.

[0043] 1. Pretreatment process

[0044] Singeing: one front and one reverse light singeing, the speed is 120m / min.

[0045]Desizing: desizing with amylase, the dosage of α-amylase is 5g / L, the dosage of non-ionic penetrating agent is 1g / L, heat preservation and desizing at 50-60℃ for 4-6h, and then wash with 5 grids of hot water at 70-80℃, Working solution pH5-6.

[0046] Bleaching: 100% hydrogen peroxide 2g / L, hydrogen peroxide stabilizer 2g / L, chelating dispersant 3g / L, heat preservation at 95-98°C for 60min, working solution pH 8-9.

[0047] Light sanding: The fabric is sanded in sequence, then ceramic sanded, and finally the cloth is produced. Among them, the cloth inlet tension is 10kg, the cloth outlet tension is 13kg, 2 rollers for sanding, 6 rollers for ceramics, the speed of sanding rollers is 1000r / min, the mesh number of sanding is 500 mesh, the s...

Embodiment 3

[0056] 106” / 40s×40s / 160×95, 4 / 1 satin, viscose:acrylic=80:20, yarn twist 100 twist / 10cm, siro compact spinning.

[0057] 1. Pretreatment process

[0058] Singeing: one front and one reverse light singeing, the speed is 110m / min.

[0059] Desizing: Desizing with amylase, the dosage of α-amylase is 10g / L, the dosage of non-ionic penetrant is 2g / L, heat preservation and desizing at 50-60℃ for 4-6h, and then wash with 5 grids of hot water at 70-80℃, Working solution pH5-6.

[0060] Bleaching: 100% hydrogen peroxide 1g / L, hydrogen peroxide stabilizer 1g / L, chelating dispersant 2g / L, heat preservation at 95-98°C for 70min, working solution pH 8-9.

[0061] Light sanding: The fabric is sanded in sequence, then ceramic sanded, and finally the cloth is produced. Among them, the cloth inlet tension is 8kg, the cloth outlet tension is 11kg, 2 rollers for sanding, 6 rollers for ceramics, the speed of sanding rollers is 1000r / min, the mesh number of sanding is 600 mesh, the speed of cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com