Mildew-proof, bacteriostatic and anti-virus PE pipe

An anti-mildew, anti-bacterial and anti-virus technology, applied in tubular articles, applications, household appliances, etc., can solve the problems of reducing toughness and fracture resistance, inability to fuse the inner and outer layers, shortening the service life, etc., to improve the toughness. and the effect of fracture resistance, improved inclusion, and improved toughness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

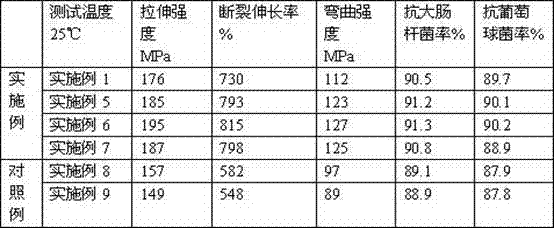

Examples

Embodiment 1

[0021] An anti-mildew, anti-bacteria and anti-virus PE pipe, its raw material composition and weight ratio are: 100 parts of polyethylene, 60 parts of phenolic resin, 60 parts of ceramic particles, 8 parts of carbon fiber, 8 parts of graphite, 6 parts of glass fiber, nano-bamboo charcoal 0.8 parts of fiber, 0.8 parts of nano-silver powder, 5 parts of compatibilizer, and 0.5 parts of antioxidant.

[0022] The fiber diameter of the carbon fiber is 5 μm-6 μm, and the fiber length is 170 μm-250 μm.

[0023] The compatibilizer is maleic anhydride.

[0024] The antioxidant is 1010 antioxidant.

Embodiment 2

[0026] An anti-mildew, anti-bacterial and anti-virus PE pipe, its raw material composition and weight are: 100 parts of polyethylene, 70 parts of phenolic resin, 70 parts of ceramic particles, 12 parts of carbon fiber, 12 parts of graphite, 9 parts of glass fiber, nano-bamboo charcoal fiber 1.0 parts, 1.0 parts of nano-silver powder, 6 parts of compatibilizer, and 0.6 parts of antioxidant.

[0027] The fiber diameter of the carbon fiber is 7 μm-8 μm, and the fiber length is 250 μm-330 μm.

[0028] The compatibilizer is maleic anhydride.

[0029] Described antioxidant is PS802 antioxidant.

Embodiment 3

[0031] An anti-mildew, anti-bacterial and anti-virus PE pipe, its raw material composition and weight ratio are: 100 parts of polyethylene, 80 parts of phenolic resin, 80 parts of ceramic particles, 16 parts of carbon fiber, 16 parts of graphite, 12 parts of glass fiber, nano-bamboo charcoal 1.2 parts of fiber, 1.2 parts of nano-silver powder, 7 parts of compatibilizer, and 0.7 parts of antioxidant.

[0032] The fiber diameter of the carbon fiber is 8 μm-9 μm, and the fiber length is 330 μm-410 μm.

[0033] The compatibilizer is acrylate.

[0034] The antioxidant is 1076 antioxidant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com