Flotation technology of micro-fine particle inbuilt state copper ore

A technology for copper ore and microfine particles, applied in flotation, solid separation, grain processing, etc., can solve the problems of copper smelting production difficulties, low recovery rate of concentrate, easy flotation, etc., and achieve excellent separation effect and chemical system advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

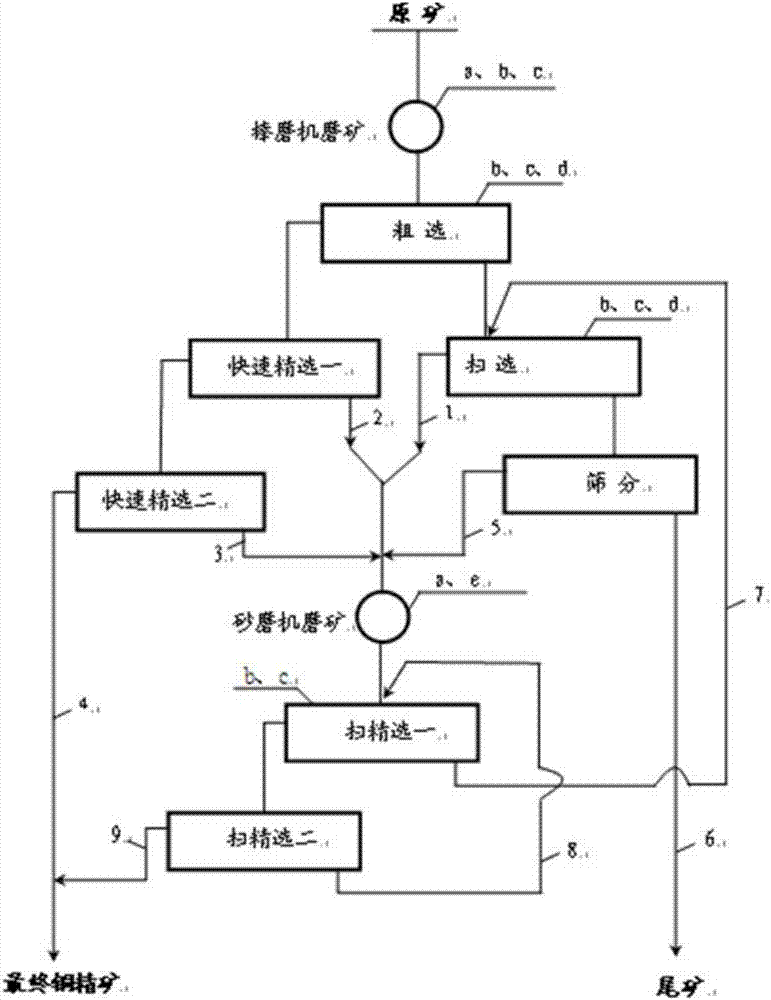

[0035] Example 1:: According to figure 1In the embodiment of the method of the present invention, the raw ore crushed to -2mm is fed into a rod mill for grinding, and the amount of calcium oxide 1020g / t and butyl xanthate are added to the rod mill according to the dry weight of each ton of raw ore The amount of butyl ammonium black medicine is 31g / t each, and the grinding fineness of the discharged pulp is -0.053mm, which accounts for 86%. At this time, the pH value of the pulp is about 9.9. Add 31g / t of butyl xanthate and butylammonium black medicine to the flotation machine, stir for 2 minutes, then add 13g / t of MIBC, stir for 1 minute, and carry out roughing; add butyl to the roughing tailings The dosage of xanthate and butyl ammonium black medicine is 11g / t each, stir for 2 minutes, then add MIBC dosage of 7g / t, stir for 1 minute, and carry out sweeping; do not add any chemicals to the roughing concentrate, and control the flotation concentration of 12 %, carry out the fi...

Embodiment 2

[0036] Embodiment 2: according to figure 1 The embodiment of the method of the present invention, the specific steps, process parameters, and medicament system are exactly the same as those in Example 1.

Embodiment 3

[0037] Embodiment 3: according to figure 1 The embodiment of the method of the present invention, the specific steps, process parameters, and medicament system are exactly the same as those in Example 1.

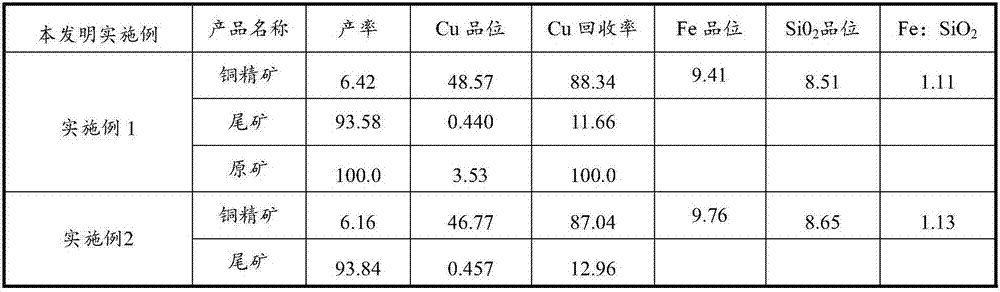

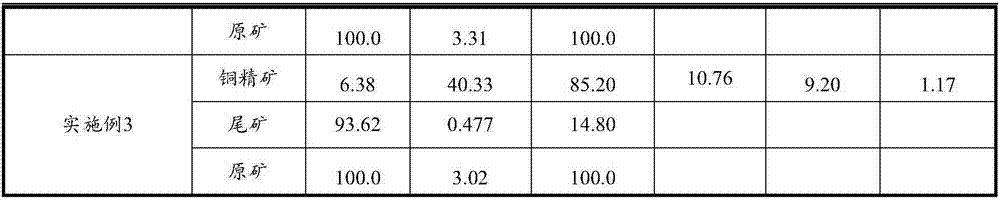

[0038] The process indexes of embodiment 1, embodiment 2 and embodiment 3 of the present invention are shown in Table 1.

[0039] Each embodiment result of table 1

[0040]

[0041]

[0042] Shown by the implementation result of embodiment 1, embodiment 2, embodiment 3 shown in table 1, adopt the inventive method, the copper concentrate copper grade that embodiment 1 obtains is 48.57%, copper recovery rate 88.34%, Fe: SiO 2 =1.11; The copper concentrate copper grade that embodiment 2 obtains is 46.77%, and copper recovery rate is 87.04%, Fe: SiO 2 =1.13; The copper concentrate copper grade that embodiment 3 obtains is 40.33%, and copper recovery rate is 85.20%, and Fe: SiO 2 = 1.17. The method of the invention has strong adaptability to ore, reliable product qualit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com