Wet desulfurization, denitrification and dust removal integrated method and device

A technology for denitrification, dust removal and wet desulfurization, which is applied in gas treatment, separation methods, and the use of liquid separation agents, etc., can solve the problems of high equipment loss and operating costs, poor gas-liquid mass transfer effect, and large liquid-gas ratio. The effect of improving desulfurization effect and improving dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

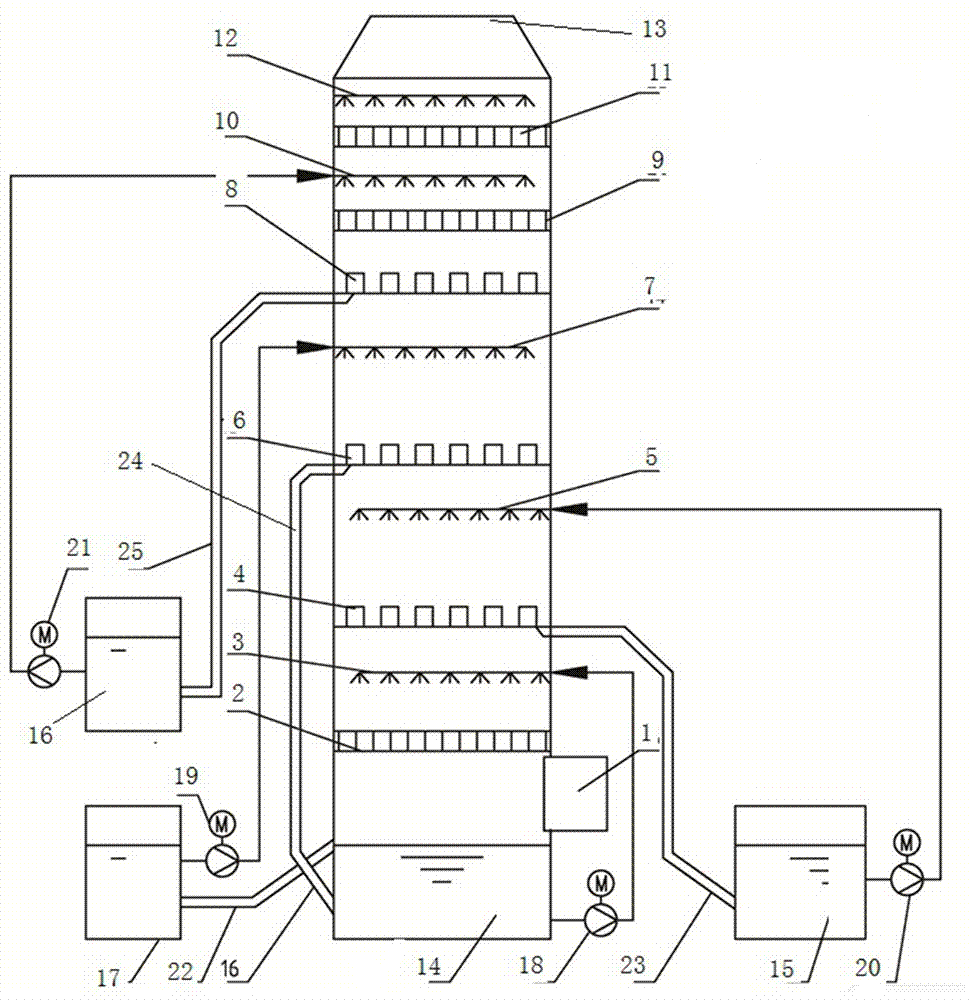

[0051] Such as figure 1 As shown, the flue gas parameters of a 130t circulating fluidized bed boiler are: the standard flue gas volume is 180000Nm³ / h, the inlet flue gas temperature is 140°C, the dry basis sulfur dioxide concentration is 3000mg / Nm³, and the dry basis nitrogen oxide concentration is 400mg / Nm³, the dust concentration on a dry basis after passing through the bag filter is 50 mg / Nm³, and the oxygen content is 11%.

[0052] The design diameter of the absorption tower is 5.4m, the superficial gas flow velocity in the tower is 3.36m / s, the number of conduits of the gas-lifting liquid collector is 16, and the diameter is 450mm. The number of dust removal pipes of the dust collector is 85, and the diameter is 450mm, using sodium chlorite as oxidizing agent and sodium hydroxide as alkaline absorbent. After testing, the desulfurization efficiency is greater than 99.5%, the denitrification and oxidation efficiency is greater than 87%, and the dry dust concentration af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com