Antimicrobial nano-particle preparation method using metal-organic framework as biocarrier for packing medicine

A metal-organic framework, antibacterial nanoparticle technology, applied in the field of nanomaterials, can solve the problems of poor thermal stability and chemical stability of antibacterial particles, inability to control drug release, poor biocompatibility, etc. Value-added, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

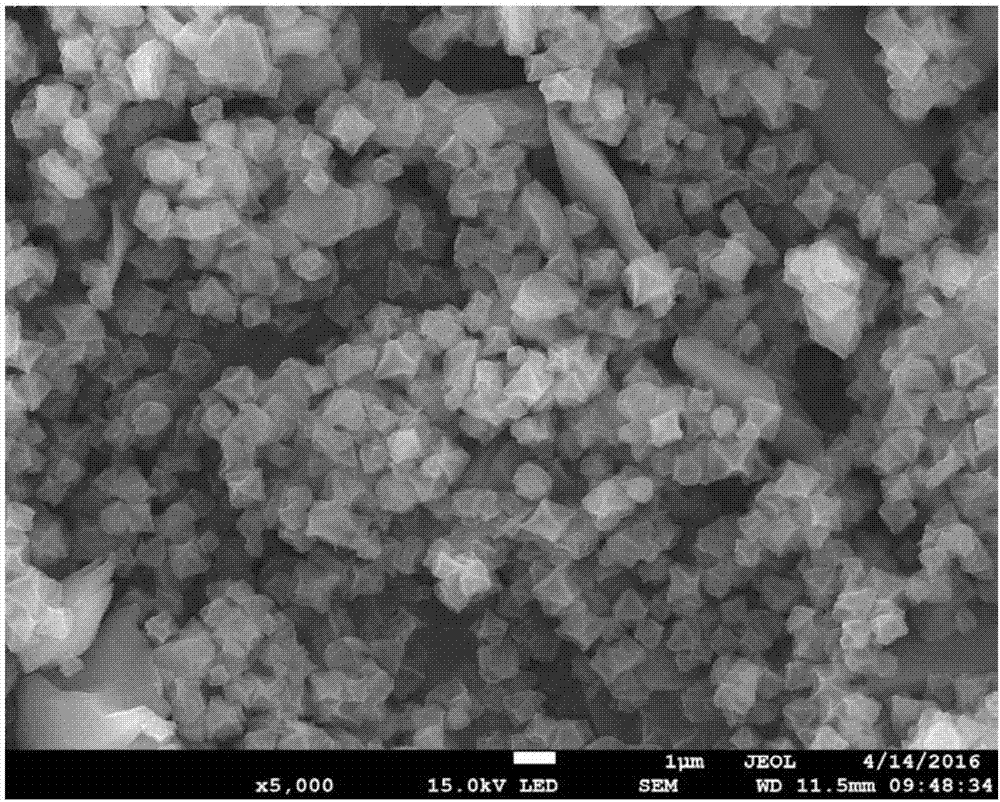

[0030] S1. Dissolve 72.09mg of ferric chloride hexahydrate and 44.3mg of terephthalic acid in 40mL N,N-dimethylformamide respectively, and then magnetically stir for 30min at room temperature to dissolve the two precursors. Put it into the same polytetrafluoroethylene reactor lining, and stir it magnetically for 20 minutes, so that the two precursor solutions are fully mixed;

[0031] The volume of the polytetrafluoroethylene reactor is 100ml;

[0032] S2. Put the inner liner of the reaction kettle on the steel sleeve and place it in an oven, heat up to 150° C. at a rate of 2° C. per minute, then react at a constant temperature for 72 hours, and place the reaction kettle at the tuyere for two hours to cool it down;

[0033] S3. Centrifuge the material cooled in step S2 at 8000 rpm for 15 minutes, collect the precipitate, and then wash and filter the product with N,N-dimethylformamide solution, deionized water, and ethanol solution in sequence to obtain metal organic framework ...

Embodiment 2

[0037] S1. Dissolve 54mg of ferric chloride hexahydrate and 33.2mg of terephthalic acid in 30mL of N,N-dimethylformamide respectively, and then magnetically stir for 30min at room temperature to dissolve the two precursors. Put it into the same polytetrafluoroethylene reactor lining, and stir it magnetically for 20 minutes, so that the two precursor solutions are fully mixed;

[0038] The volume of the polytetrafluoroethylene reactor is 100ml;

[0039] S2. Put the inner liner of the reaction kettle on the steel sleeve and place it in an oven, raise the temperature to 160° C. at a rate of 1° C. per minute, then react at a constant temperature for 72 hours, and place the reaction kettle at the tuyere for 1 hour to cool it down;

[0040] S3. Centrifuge the material cooled in step S2 at 9000rpm for 12min, collect the precipitate, and then wash and filter the product with N,N-dimethylformamide solution, deionized water and ethanol solution successively to obtain metal organic Skel...

Embodiment 3

[0044] S1. Dissolve 27mg of ferric chloride hexahydrate and 16.6mg of terephthalic acid in 15mL of N,N-dimethylformamide respectively, and stir magnetically at room temperature for 30min to dissolve them to prepare two kinds of precursors. Put it into the same polytetrafluoroethylene reactor lining, and stir it magnetically for 20 minutes, so that the two precursor solutions are fully mixed;

[0045] The volume of the polytetrafluoroethylene reactor is 50ml;

[0046] S2. Put the inner liner of the reaction kettle on the steel sleeve and place it in an oven, heat up to 170° C. at a rate of 2° C. per minute, then react at a constant temperature for 48 hours, and place the reaction kettle at the tuyere for two hours to cool it down;

[0047] S3. Centrifuge the material cooled in step S2 at 10,000 rpm for 10 minutes, collect the precipitate, and then wash and filter the product with N,N-dimethylformamide solution, deionized water, and ethanol solution in sequence to obtain metal o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com