Cleaning agent for solar panel

A technology for solar panels and cleaning agents, applied in the field of cleaning agents, can solve the problems of incomplete cleaning, complicated operation, large workload, etc., and achieve the effects of wide temperature adaptability, overcoming high labor costs, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

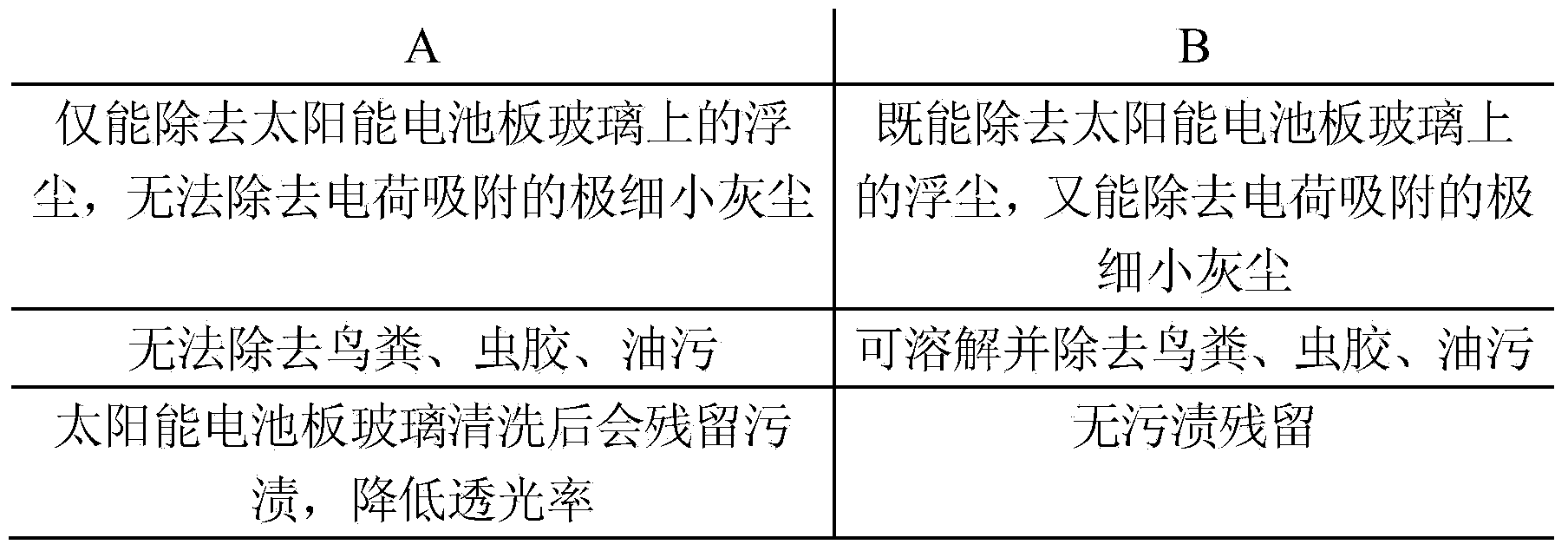

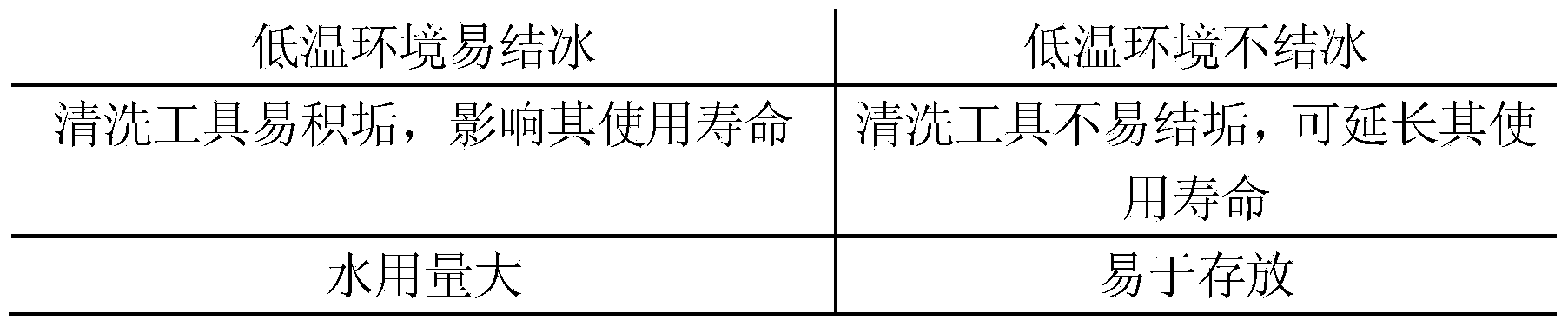

Problems solved by technology

Method used

Image

Examples

Embodiment 1

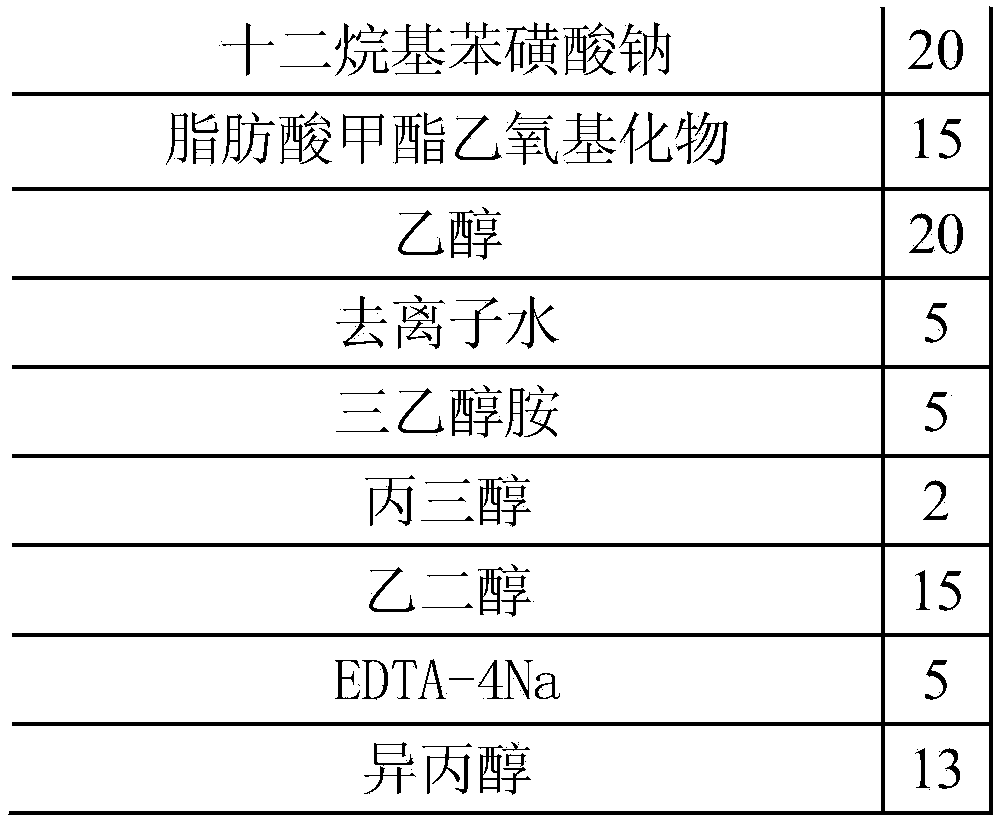

[0027] Embodiment 1: solar cell panel cleaning agent comprises the component of following mass percent:

[0028]

[0029] This solar cell panel cleaning agent is added to water to clean the solar cell panel.

[0030] The solar panel cleaning agent has strong decontamination ability, low foaming, no damage to the glass surface, no peculiar smell, non-toxic and non-corrosive.

Embodiment 2

[0031] Embodiment 2: solar cell panel cleaning agent comprises the component of following mass percent:

[0032]

[0033] This solar cell panel cleaning agent is added to water to clean the solar cell panel.

[0034] The solar panel cleaning agent has strong decontamination ability, antistatic, no damage to the glass surface, no peculiar smell, non-toxic and non-corrosive.

Embodiment 3

[0036] Solar panel cleaning agent comprises the following components in mass percentage:

[0037]

[0038] This solar cell panel cleaning agent is added to water to clean the solar cell panel.

[0039] The solar panel cleaning agent has strong decontamination ability, low foaming, no damage to the glass surface, no peculiar smell, non-toxic, non-corrosive, non-flammable, non-explosive, and non-polluting environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com