LED (Light Emitting Diode) chip photoetching developing method

A technology of LED chip and development method, applied in optics, photography, optomechanical equipment, etc., can solve the problem of high production cost of photolithography development process, achieve low cost, fast development speed, and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

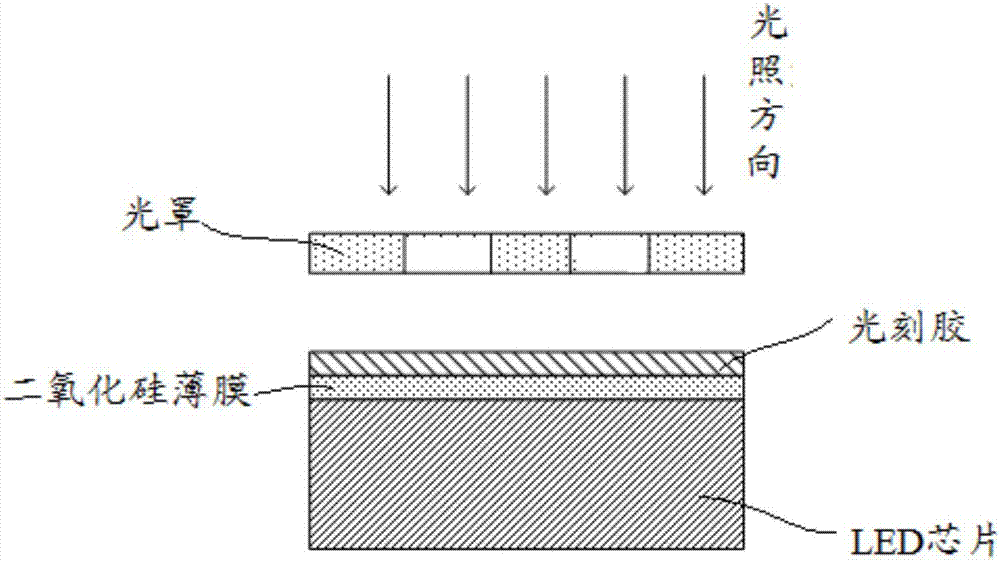

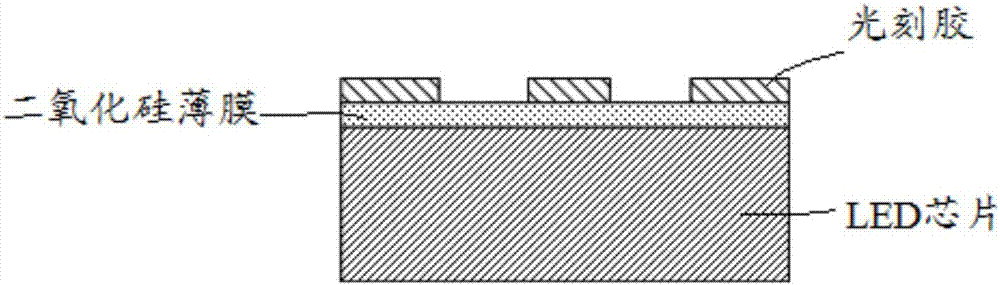

[0032] refer to figure 1 , figure 2 , image 3 with Figure 4 , the embodiment of the present invention provides a LED chip photolithographic development method, comprising the following steps:

[0033] Step S101: cleaning the surface of the LED chip;

[0034] Step S102: preparing a layer of silicon dioxide film on the LED chip by using the plasma enhanced chemical vapor deposition method;

[0035] Step S103: uniformly coating a layer of photoresist with a thickness of 3 μm on the prepared silicon dioxide film;

[0036] Step S104: Perform graphic exposure processing on the LED chip through the exposure machine and the mask, and the schematic diagram of the exposure processing on the LED chip is as follows: figure 2 shown;

[0037] Step S105: Use a developer to develop the photoresist. The developing time is 60 seconds, and the developing temperature is 20°C-40°C. The schematic diagram of the structure of the LED chip after the developing process is as follows: image ...

Embodiment 2

[0043] This embodiment provides a preferred LED chip photolithographic development method. In the LED chip photolithographic development method provided by this embodiment, the same steps as those in the above-mentioned embodiment 1 will not be repeated here. The main difference is that this embodiment In 2, when using the developing solution to develop the photoresist, the preparation method of the developing solution is as follows:

[0044] The raw materials for developer preparation are potassium hydroxide with a mass fraction of 38% to 40%, ammonia water and pure water with a mass fraction of 25% to 28%;

[0045] Under the temperature condition of 18°C to 25°C, first weigh a certain amount of potassium hydroxide, then add a certain amount of pure water, stir evenly, and finally add a certain amount of ammonia water, stir evenly, and finally obtain potassium hydroxide with a mass ratio of 2 %, the ammonia water mass accounts for 5%, and the pure water mass accounts for 93...

Embodiment 3

[0048] This embodiment provides a method for photolithography and development of LED chips, including the following steps:

[0049] Step S201: cleaning the surface of the LED chip to remove pollutants, particles, organic matter, etc. on the surface of the LED chip;

[0050] Step S202: preparing a layer of silicon dioxide film on the LED chip by using the plasma enhanced chemical vapor deposition method;

[0051] Step S203: Evenly coat a layer of photoresist with a thickness of 3 μm on the prepared silicon dioxide film, specifically, add photoresist on the LED chip, and rotate the LED chip at a speed of 1000-2000 rpm for uniform coating. Adhesive, LED chip speed and photoresist addition amount and viscosity match to ensure uniform coating of photoresist;

[0052] Step S204: Place the LED chips evenly coated with photoresist in an oven, and bake them at 95°C for 2 minutes, pre-bake the LED chips evenly coated with photoresist, and remove the particles in the photoresist. Solve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com