Anti-corrosion concrete component and pouring method thereof

A corrosion-resistant concrete and concrete technology, applied in building components, buildings, structural elements, etc., can solve problems such as chloride ions easily corroded steel bars, concrete bending resistance, shear resistance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

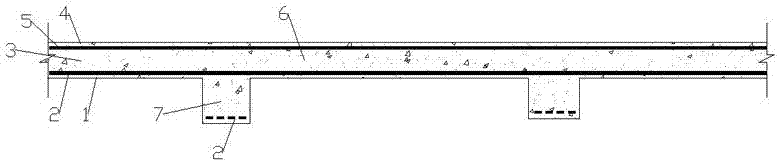

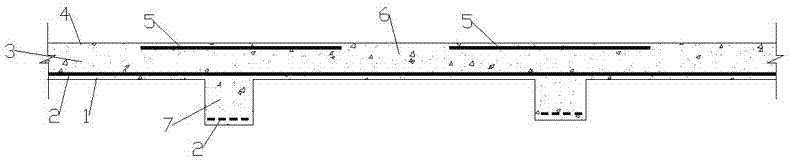

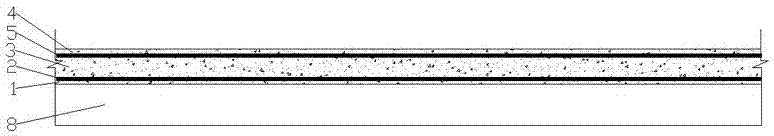

[0024] refer to figure 1 As shown, the novel corrosion-resistant concrete member provided by the present invention contains seawater and / or sea sand, or the corrosion-resistant concrete member is in an acid-base environment, and the corrosion-resistant concrete member includes bottom concrete 1, lower high-performance fiber The mesh 2 and the upper layer of concrete, the upper layer of concrete penetrates into the grid of the lower high-performance fiber mesh 2, and the lower high-performance fiber mesh 2 is located at the place where the positive bending moment at the bottom of the corrosion-resistant concrete member is concentrated.

[0025] refer to figure 1 As shown, in order to resist the negative bending moment on the upper part, the upper layer of concrete includes a middle layer of concrete 3 and a top layer of concrete 4, and an upper high-performance fiber mesh 5 is arranged between the middle layer of concrete 3 and the top layer of concrete 4, and the top layer of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com