Near-infrared fluorescent powder and preparation method thereof

A fluorescent powder and near-infrared technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of poor anti-interference, indifference, and low sensitivity, and achieve good stability, high luminous intensity, and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

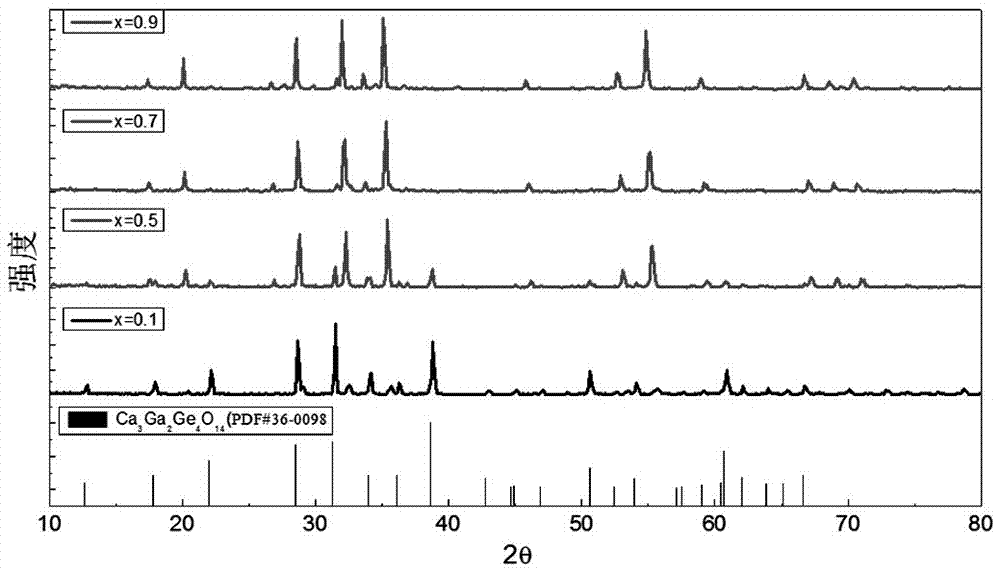

Embodiment 1

[0023] (1) Weigh each raw material according to the following weight: Weigh calcium carbonate (CaCO 3 ) 1.0009g, gallium oxide (Ga 2 o 3 ) 0.6092g, chromium trioxide (Cr 2 o 3 ) 0.0127g and germanium oxide (Ge 2 o 3 ) 1.3952g, mixed evenly, placed in an agate mortar and fully ground for 30min to obtain the mixture;

[0024] (2) Put the ground mixture powder in a small crucible, heat up to 1200°C at a heating rate of 5°C / min, sinter at this temperature for 4 hours, and cool naturally to room temperature to obtain a sintered body;

[0025] (3) Cool the obtained sintered body to room temperature and grind it thoroughly to obtain the chemical formula Ca 3 Ga 1.95 Cr 0.05 Ge 4 o 14 near-infrared phosphors.

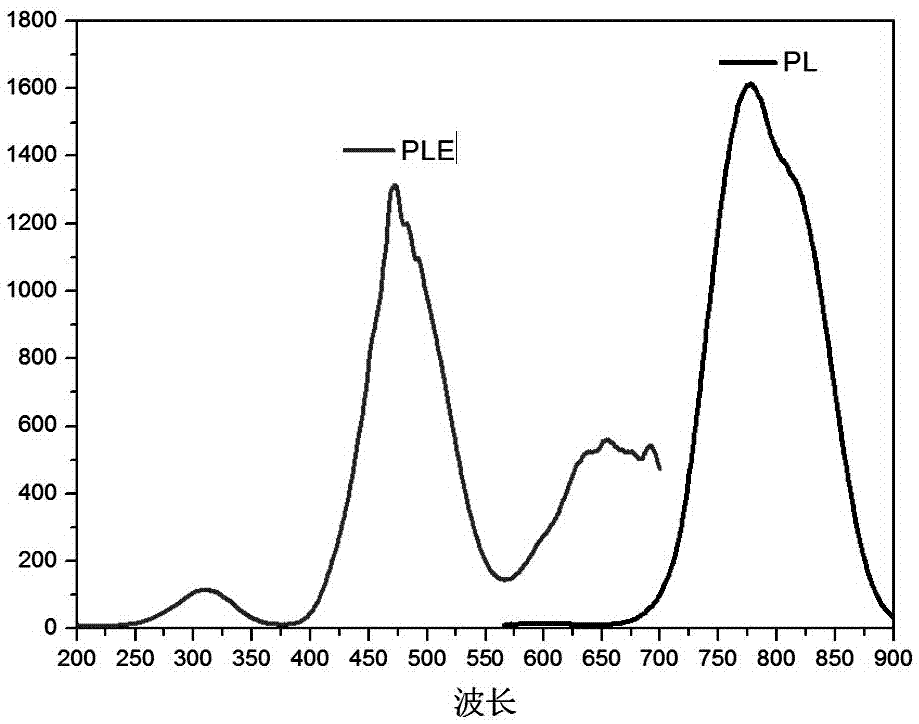

[0026] Based on the near-infrared fluorescent powder prepared in this example, its intensity and wavelength are adjusted at an emission wavelength of 745 nm.

Embodiment 2

[0028] (1) Weigh each raw material according to the following weight: Weigh calcium carbonate (CaCO 3 ) 1.0009g, gallium oxide (Ga 2 o 3 ) 0.5467g, indium oxide (In 2 o 3 ) 0.0925g, chromium trioxide (Cr 2 o 3 ) 0.0127g and germanium oxide (Ge 2 o 3 ) 1.3952g, mixed evenly, placed in an agate mortar and fully ground for 30min to obtain the mixture;

[0029] (2) Put the ground mixture powder in a small crucible, heat up to 1200°C at a heating rate of 5°C / min, sinter at this temperature for 4 hours, and cool naturally to room temperature to obtain a sintered body;

[0030] (3) Cool the obtained sintered body to room temperature and grind it thoroughly to obtain the chemical formula Ca 3 Ga 1.75 In 0.2 Cr 0.05 Ge 4 o 14 near-infrared phosphors.

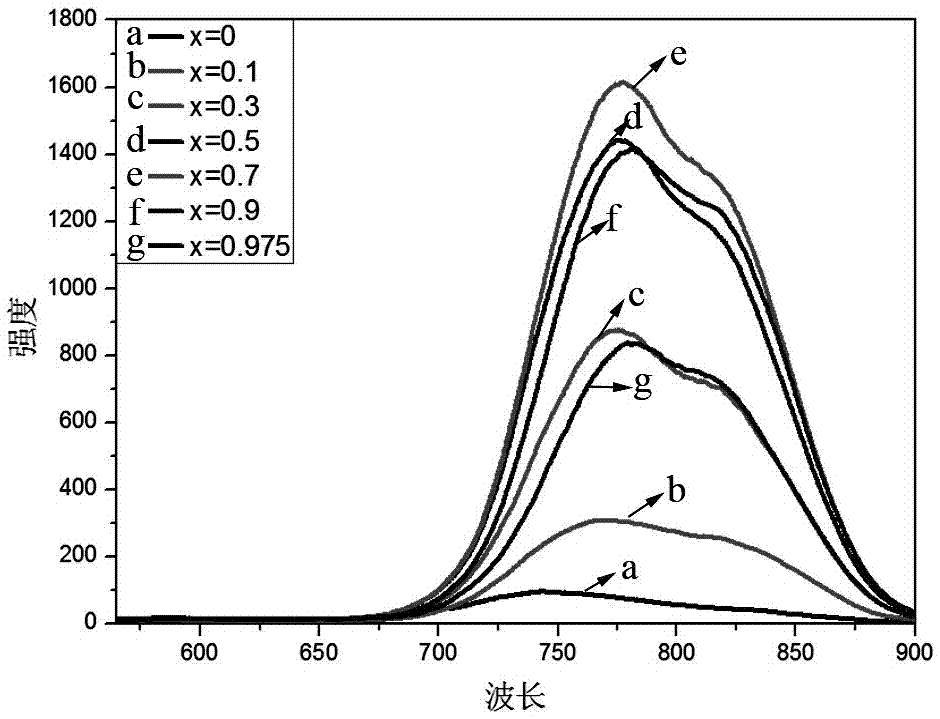

[0031] The phosphor powder prepared in this embodiment begins to appear red shift phenomenon and the emission intensity increases, and the red shift degree is the largest.

Embodiment 3

[0033] (1) Weigh each raw material according to the following weight: Weigh calcium carbonate (CaCO 3 ) 1.0009g, gallium oxide (Ga 2 o 3 ) 0.4217g, indium oxide (In 2 o 3 ) 0.2776g, chromium trioxide (Cr 2 o 3) 0.0127g and germanium oxide (Ge 2 o 3 ) 1.3952g, mixed evenly, placed in an agate mortar and fully ground for 30min to obtain the mixture;

[0034] (2) Put the ground mixture powder in a small crucible, heat up to 1200°C at a heating rate of 5°C / min, sinter at this temperature for 4 hours, and cool naturally to room temperature to obtain a sintered body;

[0035] (3) Cool the obtained sintered body to room temperature and grind it thoroughly to obtain the chemical formula Ca 3 Ga 1.35 In 0.6 Cr 0.05 Ge 4 o 14 near-infrared phosphors.

[0036] The wavelength intensity of the near-infrared phosphor prepared in this example continues to increase, and the wavelength is also red-shifted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com