Motor integrating connection and movement functions and modularized robot applying motor

A motion function and circuit technology, which is applied in the field of new electronically controlled permanent magnet motors, can solve the problems of complex mechanical lock structure, high energy requirements, and high manufacturing costs, and achieve the effect of simple structure, simplified structure, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

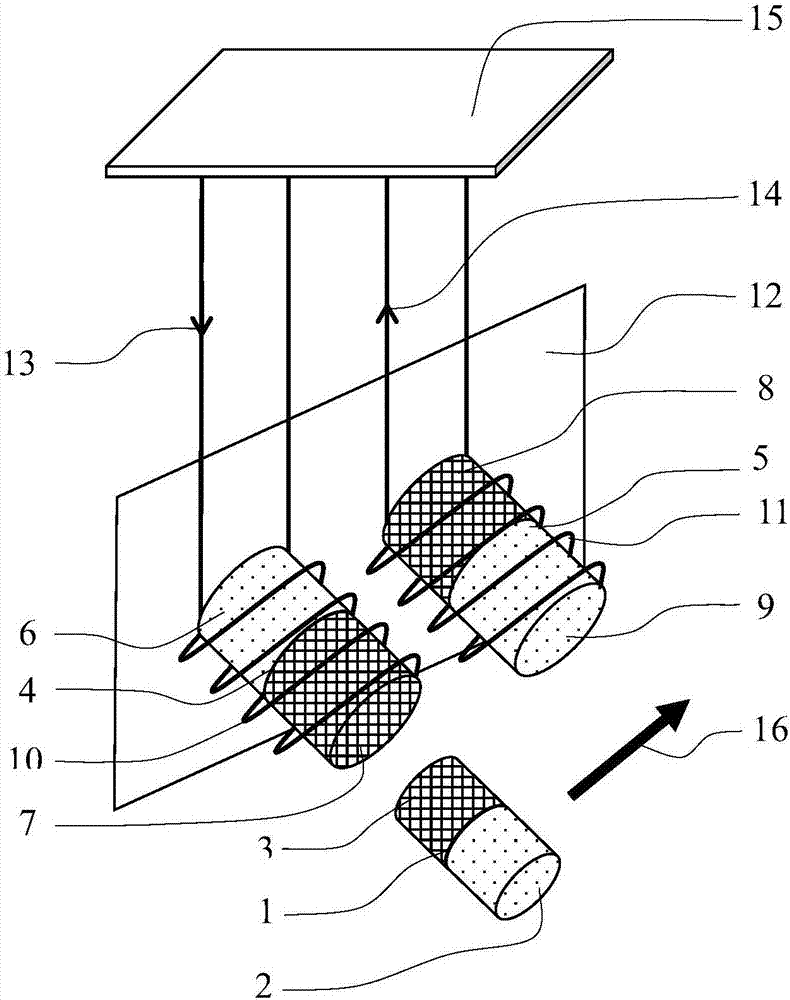

[0019] See attached figure 1 , The motor with connection and movement functions of the present invention includes 4 parts: NdFeB magnet 1, Alnico magnet 4 and 5, copper coil 10 and 11, pulse control circuit 15. The fixing plate 12 is used for fixing the alnico magnets 4 and 5 .

[0020] The pulse control circuit 15 is mainly composed of an H bridge circuit.

[0021] The NdFeB alloy magnet 1 is a cylinder, the magnetization direction is axial magnetization, and its magnetic pole is divided into a north pole 2 and a south pole 3 .

[0022] The alnico magnet 4 is evenly wound by a copper coil 10 , and its magnetization direction is also axial magnetization, and its magnetic poles are divided into north poles 6 and south poles 7 . The alnico magnet 5 is uniformly wound by a copper coil 11 , and its magnetization direction is axial magnetization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com