Novel Pipe sleeve

A new type of tube sleeve technology, applied in the field of tube sleeve, can solve the problems of single function and troublesome use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] When the present invention is used as a pen holder or a pipe sheath, the innermost layer can be fixed on the pen core or pipe with an adhesive tape, and when the long sleeve used as a short pencil can not be fixed together with the rod body to be clamped, especially When the cross-section is a perfect circle and the surface is very smooth, it is better to make one or both ends of the innermost layer of the sleeve into a shape longer than the other layers, and press the inner layer longer than the other layers on the clamped rod by hand. On the shape body, it will be more convenient and faster to roll the pipe cover and the rod shape more tightly.

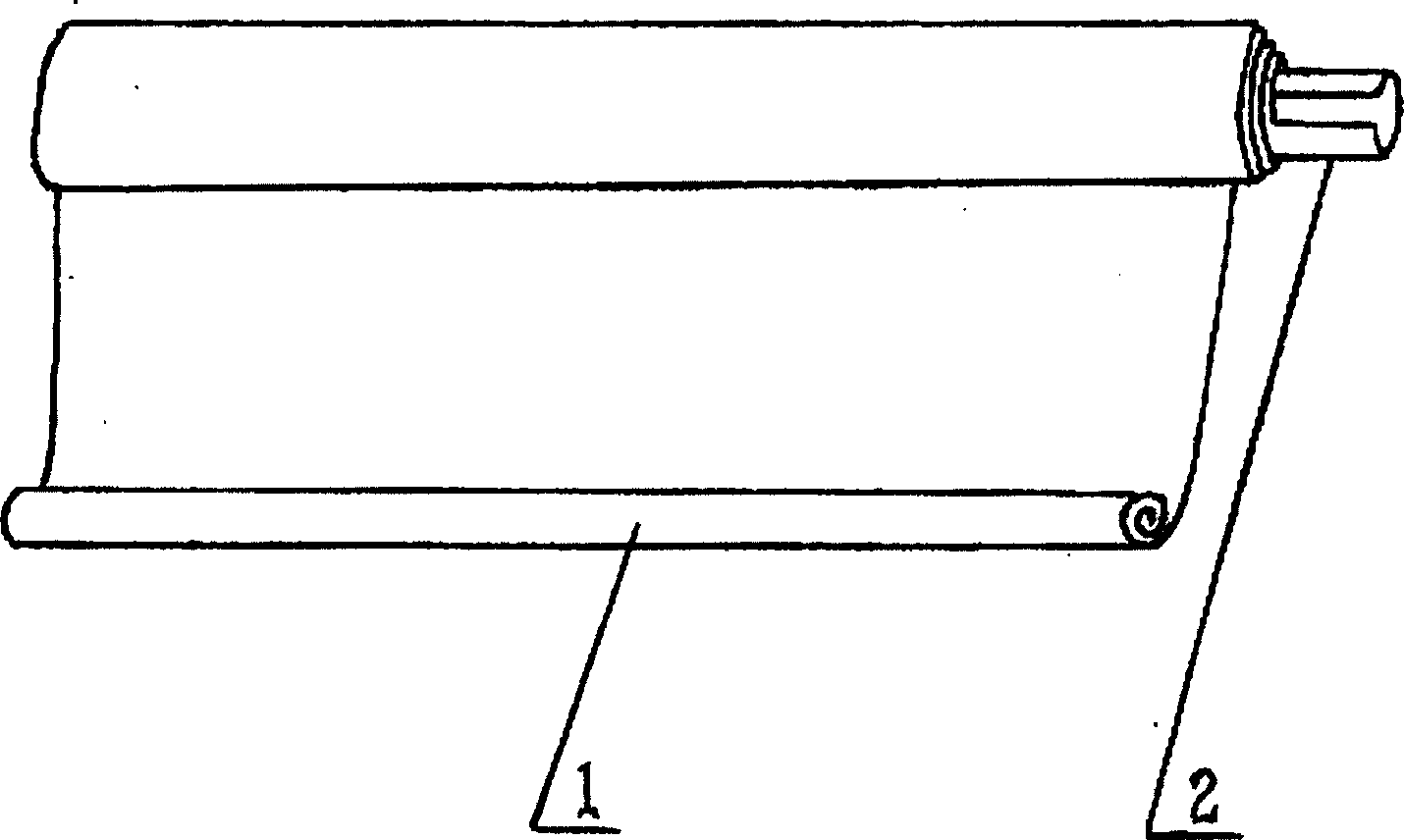

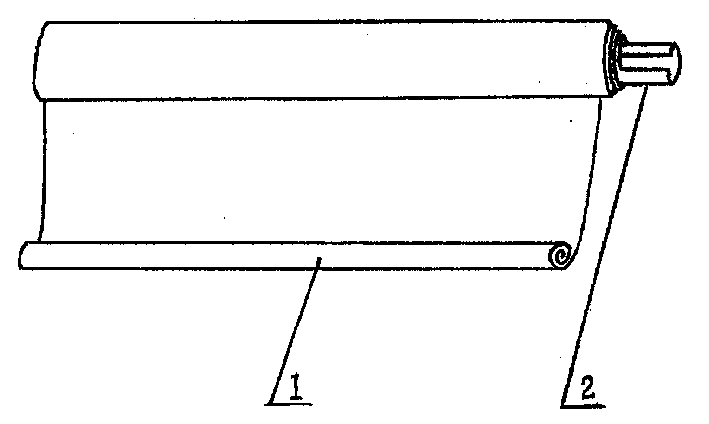

[0008] A new type of sleeve can be re-rolled from the outermost layer as the innermost layer. When a part of the sleeve is rolled up, two parallel sleeves are formed. Socket. A new type of pipe sleeve can also be made by overlapping several sections of coiled material, one end of each section is connected to each other, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com