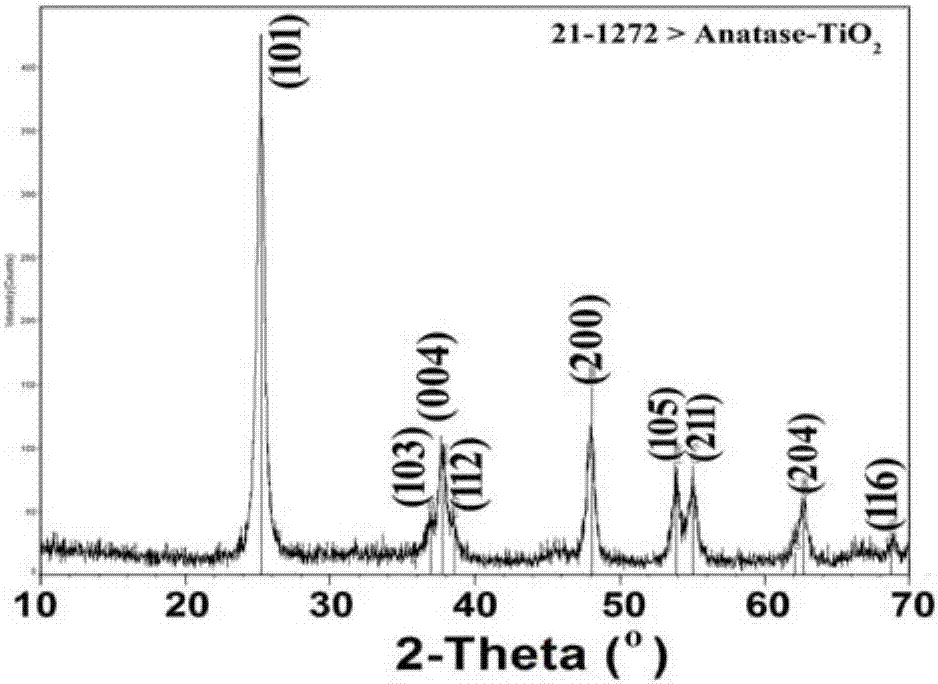

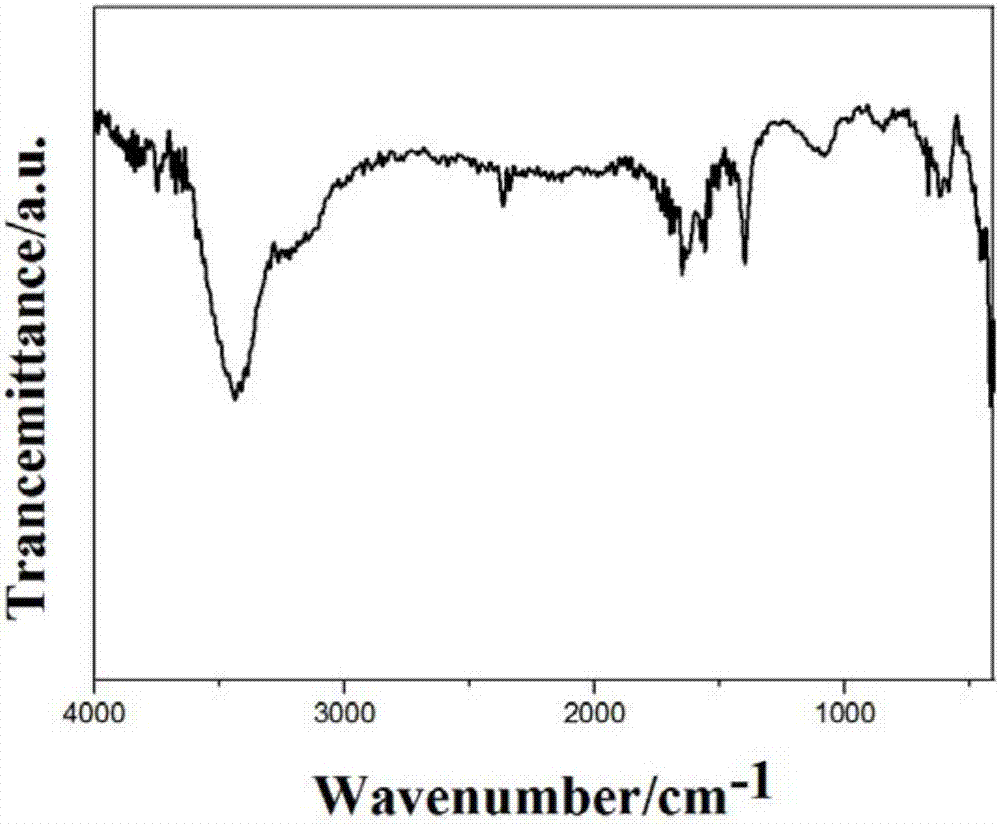

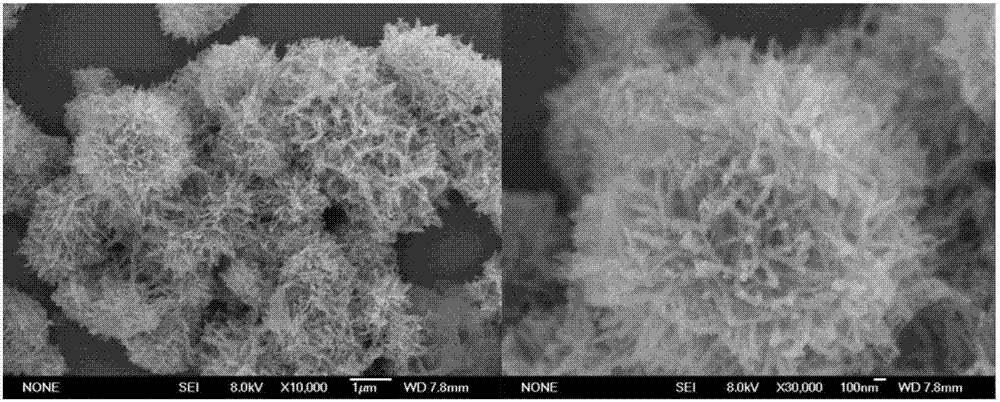

g-C3N4/TiO2 (graphite-carbon nitride/titanium dioxide) nanowire assembly structure photocatalyst and preparation method thereof

A technology for assembling structures and photocatalysts, applied in physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc. The preparation process is cumbersome and other problems, to achieve the effect of easy control of dispersion, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Dissolve 0.885g potassium titanium oxalate in deionized water, then add 4ml 30% H 2 o 2 , the solution turns orange-yellow, stir evenly, then add 8ml of NaOH solution with a concentration of 10M;

[0020] 2. Stir the above mixed solution evenly, transfer it to a reaction kettle lined with polytetrafluoroethylene, heat and react at 180°C for 3 hours, take it out and cool it to room temperature, centrifuge, and wash three times with deionized water and ethanol;

[0021] 3. Add the product obtained in step (2) to soak in hydrochloric acid with a concentration of 0.1M for 12 hours, then separate the product after acid soaking, wash it with deionized water until neutral, wash it with alcohol three times, and dry it in an oven to obtain the precursor ;

[0022] 4. Dissolve urea with ethanol, add the titanium dioxide precursor obtained in step (3), so that the mass ratio of urea to titanium dioxide precursor is 10:1, heat and evaporate the ethanol to dryness, and heat up ...

Embodiment 2

[0024] 1. Dissolve 0.885g potassium titanium oxalate in deionized water, then add 4ml 30% H 2 o 2 , the solution turns orange-yellow, stir evenly, then add 8ml of NaOH solution with a concentration of 10M;

[0025] 2. Stir the above mixed solution evenly, transfer it to a reaction kettle lined with polytetrafluoroethylene, heat and react at 180°C for 3 hours, take it out and cool it to room temperature, centrifuge, and wash three times with deionized water and ethanol;

[0026] 3. Add the product obtained in step (2) to soak in hydrochloric acid with a concentration of 0.1M for 12 hours, then separate the product after acid soaking, wash it with deionized water until neutral, wash it with alcohol three times, and dry it in an oven to obtain the precursor ;

[0027] 4. Dissolve urea with ethanol, add the titanium dioxide precursor obtained in step (3), so that the mass ratio of urea to titanium dioxide precursor is 20:1, heat and evaporate the ethanol to dryness, and heat up ...

Embodiment 3

[0029] 1. Dissolve 0.885g potassium titanium oxalate in deionized water, then add 4ml 30% H 2 o 2 , the solution turns orange-yellow, stir evenly, then add 8ml of NaOH solution with a concentration of 10M;

[0030] 2. Stir the above mixed solution evenly, transfer it to a reaction kettle lined with polytetrafluoroethylene, heat and react at 180°C for 3 hours, take it out and cool it to room temperature, centrifuge, and wash three times with deionized water and ethanol;

[0031] 3. Add the product obtained in step (2) to soak in hydrochloric acid with a concentration of 0.1M for 12 hours, then separate the product after acid soaking, wash it with deionized water until it is neutral, wash it with alcohol three times, and dry it in an oven to obtain the precursor ;

[0032] 4. Dissolve urea with ethanol, add the titanium dioxide precursor obtained in step (3), so that the mass ratio of urea to titanium dioxide precursor is 5:1, heat and evaporate the ethanol to dryness, and hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com