Manufacturing method for second cold-rolled tin-plated steel sheet of highly anti-sulfur food can

A technology for secondary cold-rolled and tin-plated steel sheets, applied in the direction of chromate treatment, etc., can solve the problems of difficult industrial production of secondary cold-rolled and tin-plated steel sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

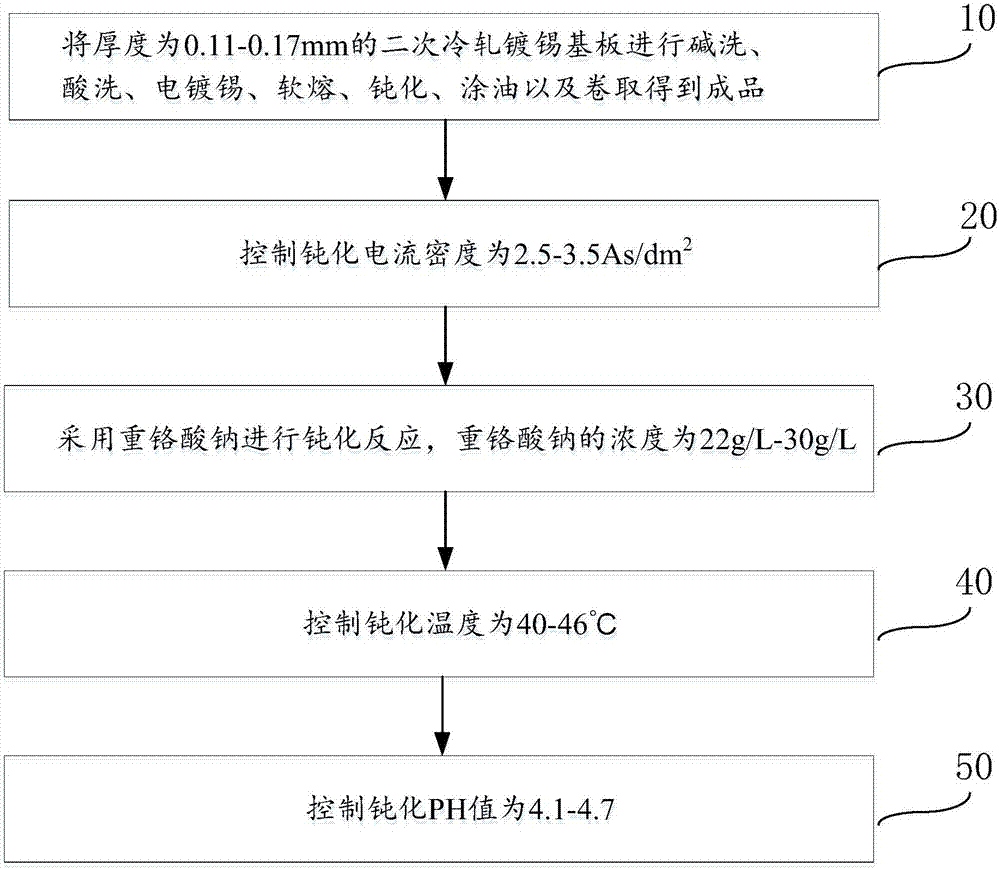

[0033] This embodiment provides a method for manufacturing a secondary cold-rolled tin-plated steel plate used for high sulfur-resistant food cans. Washing, electro-tinning, reflow, passivation, oiling, coiling to get the finished product. The yield strength of the secondary cold-rolled tin-plated substrate is 510MPa, the elongation is 6.5%, the hardness HR30T is 70, the roughness of the upper surface is 0.32μm, and the roughness of the lower surface is 0.33. The secondary cold-rolled tin-plated substrate is subjected to alkali cleaning, pickling, tinning, and reflow, and then passivated according to the method of the present invention, and then rinsed with desalted water, dried, oiled, and coiled to obtain a secondary Finished cold-rolled tinplate. Among them, the control passivation current density is 2.5As / dm 2 ; control Na 2 Cr 2 o 7 The concentration is 25.10g / L, Na 2 Cr 2 o 7 The purity is 99.5%; the passivation temperature is controlled at 42.7°C, and the passiv...

Embodiment 2

[0035] The difference between the manufacturing method of the secondary cold-rolled tin-plated steel plate used for high sulfur-resistant food cans provided in this example and Example 1 is only that: in this example, the passivation current density is controlled to be 3.0As / dm 2 . After testing, the anti-sulfur grade of the secondary cold-rolled tin-plated steel plate is Class I.

Embodiment 3

[0037] The difference between the manufacturing method of the secondary cold-rolled tin-plated steel sheet for high sulfur-resistant food cans provided in this example and Example 2 is that in this example, the passivation current density is controlled to be 3.5As / dm 2 . After testing, the anti-sulfur grade of the secondary cold-rolled tin-plated steel plate is Class I.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com