Casting method for steel-copper composite cylinder body

A casting method and composite cylinder technology, applied in cylinders, liquid chemical plating, coating, etc., can solve problems such as oxidation and substandard composite performance, and achieve improved corrosion resistance, no peeling and bubbling, and good composite performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to these embodiments.

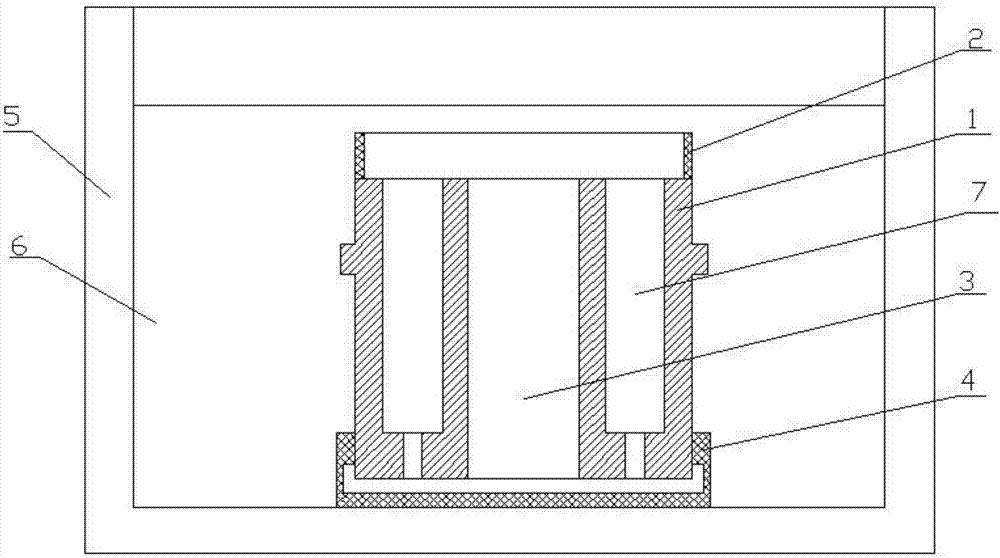

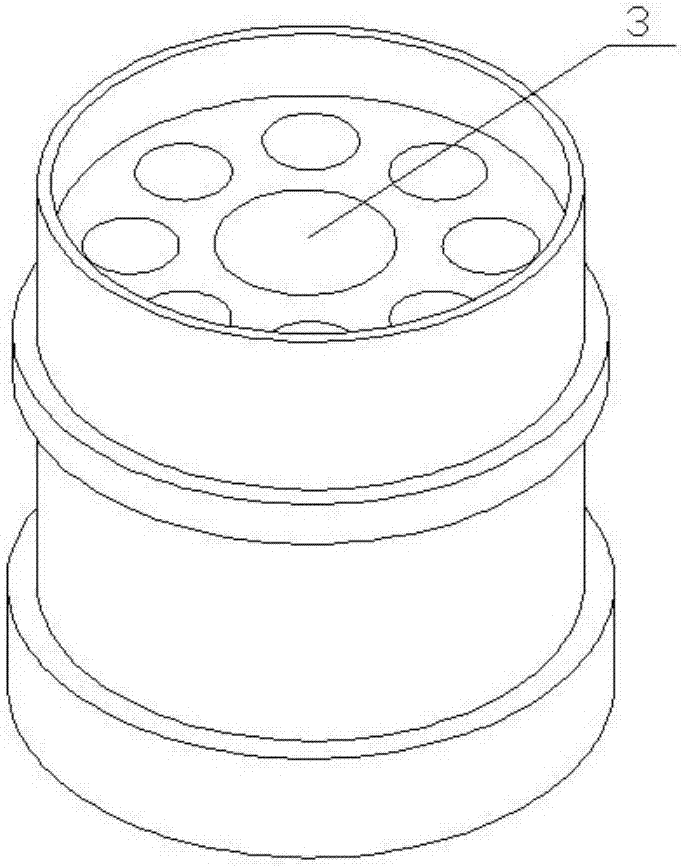

[0034] Depend on Figure 1-2 , a casting method of a steel-copper composite cylinder, comprising the following steps:

[0035] Step 1. Establish a three-dimensional model, calculate the mass of the cast copper metal to be 19.86kg, carry out casting process design and simulation, optimize the casting process, and determine that the initial temperature of the steel base is 1250°C, and the initial casting temperature of the copper metal is 1250°C. The holding time is 9-12min, the casting time is 15s, and the casting speed is 1.5kg / s;

[0036] Step 2: Use cylindrical steel billet as the steel base, and perform heat treatment and annealing process on the steel base: slowly heat to 900°C-1050°C, heat for 15h-20h and then cool to room temperature;

[0037] Step 3: Carry out turning, mil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com