Horizontal-type double-drum backwashing filter

A backwashing, double drum technology, applied in the direction of moving filter element filters, filtration separation, chemical instruments and methods, etc., can solve the problems of easy paralysis of the filter, low filtration efficiency, large energy loss and other problems, so as to solve the problem of poor cleaning. The effect of thorough, improving filtration efficiency and reducing the probability of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the application according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. The specific embodiments described here are only used to explain the invention, not to limit the invention.

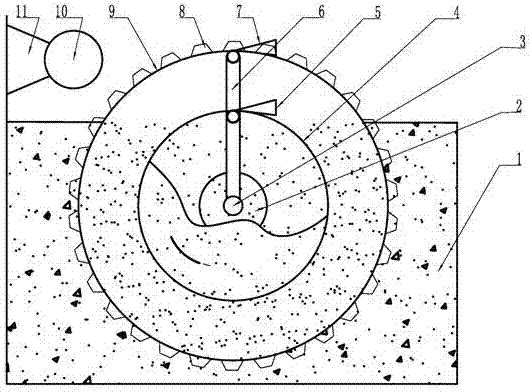

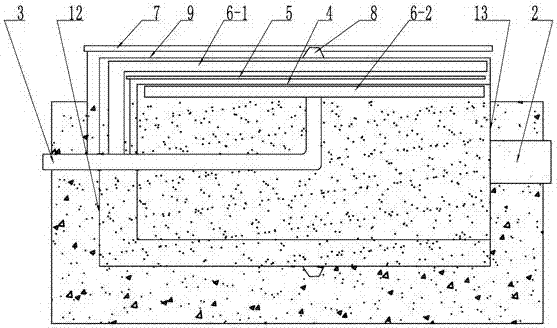

[0012] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides a kind of horizontal double drum backwash filter, comprising: coarse filter drum filter screen 9, fine filter drum filter screen 4, high pressure nozzle 6, silt collection tank 5, large particle collection Groove 7, toothed belt 8, left side cover plate 12 and right side cover plate 13, support 11 are welded with steel bar, and are installed on the one-stage filter pool 1.

[0013] The left side cover 12 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com