Method for preparing aromatic-rich bio-oil by liquefying lignin with supercritical mixed solvent

A technology for aromatic compounds and lignin, which is used in the preparation of liquid hydrocarbon mixtures, petroleum industry, processing of hydrocarbon oils, etc., can solve problems such as low chemical potential, and achieve the effects of high conversion efficiency, economical price, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

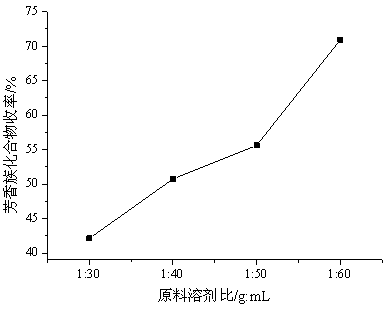

[0044] Example 1 Effect of the mass volume ratio of raw material and solvent on the yield of aromatic compounds in bio-oil

[0045] 1 Alkali lignin pretreatment

[0046] S11. Preliminary grinding and placement

[0047] Take 3~5 clean petri dishes, use a sampling spoon to spoon a part of the lignin into the mortar, crush the large-grained lignin as much as possible, then use the sampling spoon to take a small part of the lignin to the petri dish, and spread it on the petri dish At the bottom, the powder coverage height is below 1.5 mm.

[0048] S12. Preliminary drying

[0049] The petri dish and mortar in S11 were scattered and dried in a vacuum oven at 65 °C for 4 h, and vacuumed for 2–5 min every 15 min.

[0050] S13. Grinding again

[0051] After taking out the petri dish and mortar in S12, pour the lignin in the petri dish into the mortar, pulverize the large particles of lignin, and spread the lignin to the bottom of the petri dish with a sampling spoon after the pulve...

Embodiment 2

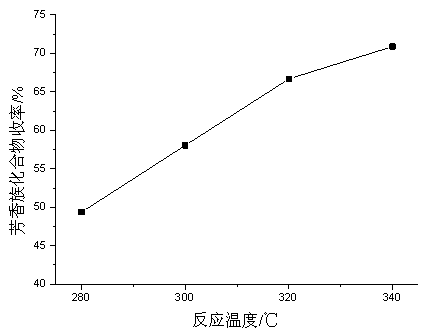

[0067] Example 2 The influence of reaction temperature on the yield of aromatic compounds in bio-oil when the reaction medium is a mixed solvent

[0068] Add 2 g of dried lignin powder with a particle size of 40-60 mesh and 120 mL of mixed solvent (methanol:ethanol 1:0.5~1:1.5) into a batch autoclave with a volume of 500 mL and a magnetic stirrer After sealing, the temperature was raised to 340 °C, and the reaction was kept at this temperature for 60 min. Cool to room temperature and collect the product.

[0069] Products that are gaseous at normal temperature and pressure are gas phase products. Wash the inner wall of the reactor with acetone, collect the solid-liquid mixed product, extract it with acetone, and filter it with a vacuum pump. The filtrate evaporates the organic solvent with a rotary evaporator, and the remaining substance is bio-oil. Finally, the acetone-insoluble material was the residual solid.

[0070] The bio-oil produced by the liquefaction of lignin at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com