Method for preparing conductive glass fibers from waste glass fibers

A conductive glass fiber and glass fiber technology, applied in the field of glass fiber, can solve problems such as explosion and fire, and achieve the effect of promoting energy saving and emission reduction, low equipment cost and realizing environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

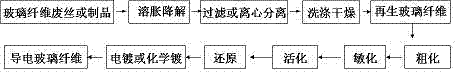

Method used

Image

Examples

Embodiment 1

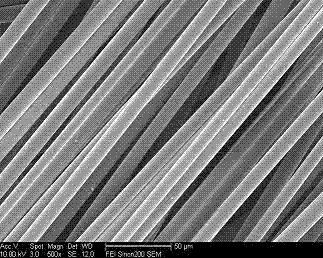

[0022] Example 1 Copper plating on the surface of recycled glass fiber waste 。

[0023] Put the glass fiber waste into a glass tank of the corresponding size, add concentrated sulfuric acid, alkylphenol polyoxyethylene ether mixture (8:2), immerse the glass fiber, soak for 2 hours at room temperature or under agitation, and then filter Or take out the glass fiber by centrifugation, wash it with clean water for several times until it is clean, dry it naturally or heat it to get the regenerated glass fiber, take 2.00 g of the regenerated glass fiber and put it in a beaker, add 3.00 g of zinc powder and stir for 2 min to make the glass fiber The fiber is in full contact with the zinc powder, and then four representative additives A (alkylbenzene sulfonate), B (alkyl sulfonate), C (lauryl fatty acid salt), D (decyl fatty acid salt) are added respectively. Dialkyl fatty acid salt+sodium acetate), after stirring for 2min, add 250 ml of 5.00% copper sulfate solution, and stir at ...

Embodiment 2

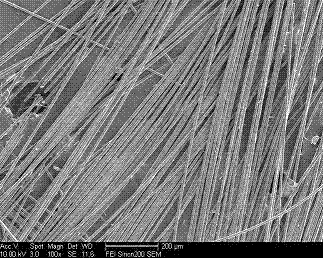

[0024] Example 2 Nickel plating on the surface of glass fiber waste 。

[0025] Put the waste glass fiber felt into a glass tank of the corresponding size, add a mixture of concentrated sulfuric acid, petroleum ether and polyethylene glycol 400 (7:2:1) to immerse the glass fiber, and soak for 1 hour under normal temperature static or stirring conditions Finally, filter or centrifuge to take out the glass fiber, wash it with clean water for several times until it is clean, dry it naturally or heat it to obtain the regenerated glass fiber, and immerse the glass fiber in the roughening solution ((NH 4 ) 2 S 2 o 8 200g / L;H 2 SO 4 100mL) at room temperature for 20min, then soak the roughened glass fibers in the sensitizing solution (SnCl 2 20g / L; HCl 40mL / L) and activation solution (PbCl2 0.25g / L; HCl2.5mL / L) were stirred at room temperature for 10min, and all pretreatment processes were carried out under ultrasonic vibration conditions to ensure their uniformity. as N...

Embodiment 3

[0026] Example 3 Silver-plated surface of glass fiber waste 。

[0027] Put the glass fiber cloth into a glass tank of the corresponding size, add the mixture of concentrated sulfuric acid, fatty alcohol polyoxyethylene ether and dioxane (4:5:1), immerse the glass fiber cloth, stand at room temperature or stir After soaking under water for 2 hours, filter or centrifuge to take out the glass fiber, wash it with clean water several times until it is clean, dry it naturally or heat it to get the regenerated glass fiber, and soak the glass fiber in the roughening solution ((NH 4 ) 2 S 2 o 8 200g / L;H 2 SO 4 100mL) at room temperature for 20min, then soak the roughened glass fibers in the sensitizing solution (SnCl 2 20g / L; HCl 40mL / L) and activation solution (PbCl 2 0.25g / L; HCl2.5mL / L) were ultrasonically stirred at room temperature for 10min. Prepared pre-treated glass fibers. To the prepared AgNO 3 Slowly add NH to the solution 3 .H 2 O, a precipitate is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com