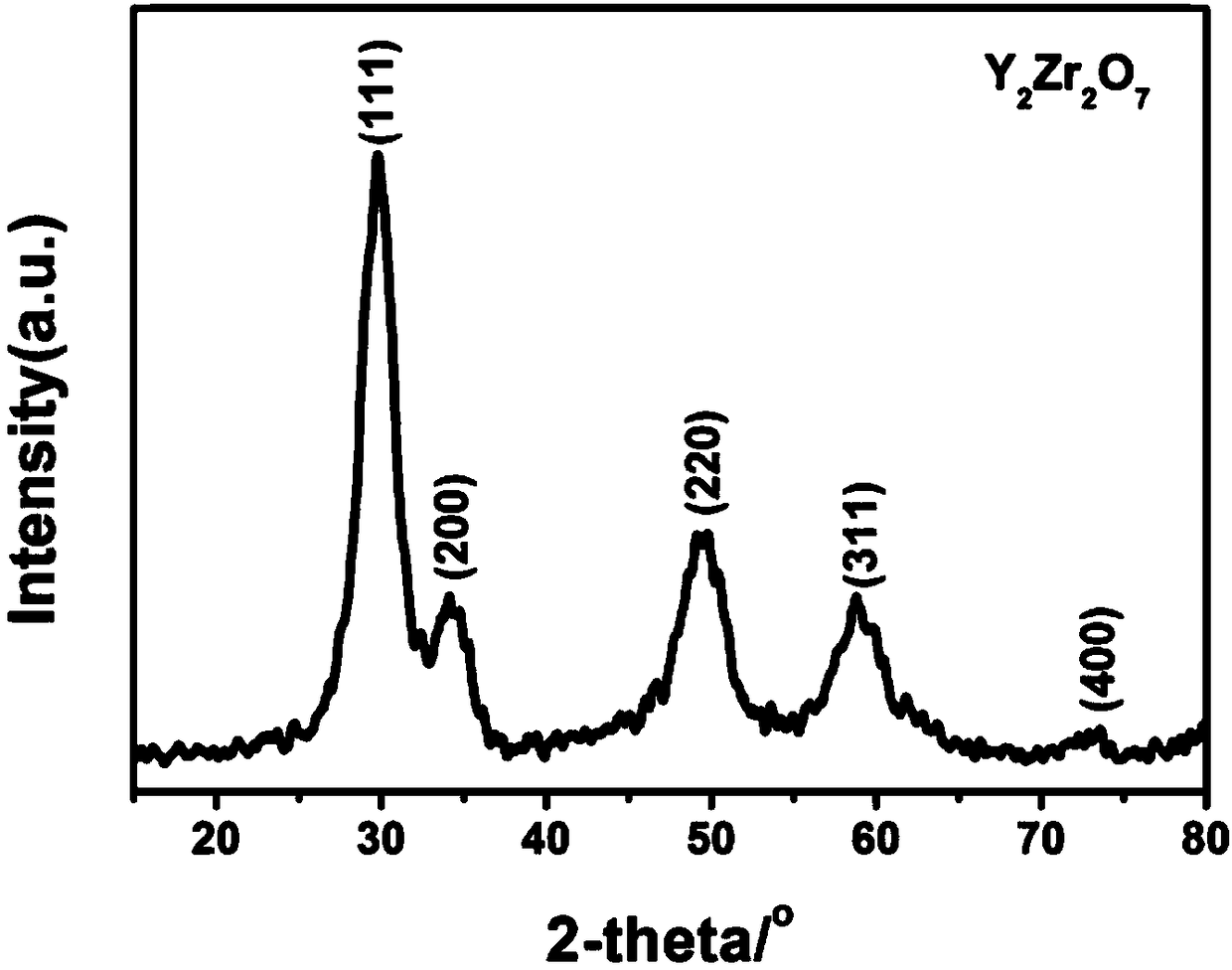

A kind of method for preparing yttrium zirconate by oxalic acid dihydrazide combustion method

A technology of oxalic acid dihydrazide and yttrium zirconate, which is applied in chemical instruments and methods, zirconium compounds, inorganic chemistry, etc., can solve the problems of high temperature of reactants, large size of generated products, and uncontrollable particle size, etc., so as to promote Rapid formation, low synthesis temperature, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Weigh the analytically pure Y(NO 3 ) 3 ·6H 2 O and ZrO(NO 3 ) 2 ·H 2 Dissolve O in a beaker with deionized water to prepare a solution with a Y ion concentration of 0.1 mol / L, wherein the molar ratio of Y to Zr is 1:1.

[0027] 2) Using oxalic acid dihydrazide as complexing agent and combustion agent, adding 1 mol / L oxalic acid dihydrazide aqueous solution into the stirred solution by dropwise addition to obtain a mixed solution; wherein, oxalic acid dihydrazide and Y(NO 3 ) 3 ·6H 2 The molar ratio of O is 2:1.

[0028] 3) After stirring for 2 hours with a magnetic stirrer at a speed of 350 rpm, a stable mixed solution is obtained, and the stable mixed solution is placed in a constant temperature magnetic stirrer, and the temperature is controlled at 60 ° C. After 5 hours in a water bath, the excess water is evaporated to obtain a white color gel.

[0029] 4) Place the obtained white gel in a muffle furnace that has been preheated to 350° C., and react for ...

Embodiment 2

[0032] 1) The analytically pure Y(NO 3 ) 3 ·6H 2 O and ZrO(NO 3 ) 2 ·H 2Dissolve O in a beaker with deionized water to prepare a solution with a Y ion concentration of 0.2 mol / L, where the molar ratio of Y to Zr is 1:1.

[0033] 2) Using oxalic acid dihydrazide as complexing agent and combustion agent, adding 1 mol / L oxalic acid dihydrazide aqueous solution into the stirred solution by dropwise addition to obtain a mixed solution; wherein, oxalic acid dihydrazide and Y(NO 3 ) 3 ·6H 2 The molar ratio of O is 3:1.

[0034] 3) After stirring for 2 hours with a magnetic stirrer at a speed of 500 rpm, a stable mixed solution is obtained, and the stable mixed solution is placed in a constant temperature magnetic stirrer, and the temperature is controlled at 80°C. After 5 hours in a water bath, the excess water is evaporated to obtain a white color gel.

[0035] 4) Put the obtained white gel in a muffle furnace whose temperature has been preheated to 350° C., and react for ...

Embodiment 3

[0040] 1) The analytically pure Y(NO 3 ) 3 ·6H 2 O and ZrO(NO 3 ) 2 ·H 2 Dissolve O in a beaker with deionized water to prepare a solution with a concentration of 0.3 mol / L, wherein the molar ratio of Y to Zr is 1:1.

[0041] 2) Using oxalic acid dihydrazide as complexing agent and combustion agent, add 1.5mol / L oxalic acid dihydrazide aqueous solution into the stirred solution by dropwise addition to obtain a mixed solution; wherein, oxalic acid dihydrazide with Y(NO 3 ) 3 ·6H 2 The molar ratio of O is 3:1.

[0042] 3) Stirring with a magnetic stirrer at a speed of 400 rpm for 3 hours to obtain a stable mixed solution, put the stable mixed solution into a constant temperature magnetic stirrer, control the temperature at 70°C, and evaporate the excess water after 4 hours in a water bath to obtain a white gel.

[0043] 4) Put the obtained white gel in a muffle furnace whose temperature has been preheated to 400° C., and react for 15 minutes to promote the combustion o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com