Large-caliber thermoplastic composite long-distance transportation pipe and manufacturing method and device thereof

A composite material and manufacturing device technology, which is applied in manufacturing auxiliary devices, rigid pipes, additive manufacturing, etc., can solve rare problems and achieve the effects of smooth inner wall, constant tension, high fluid velocity and flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

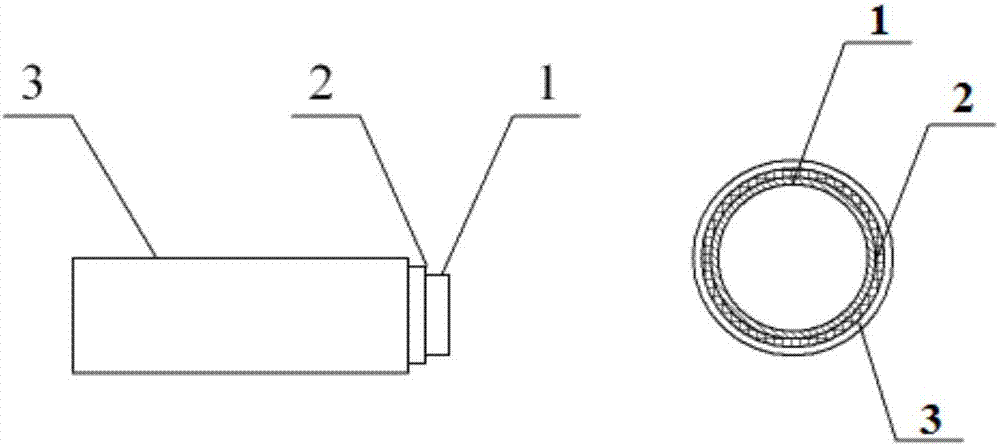

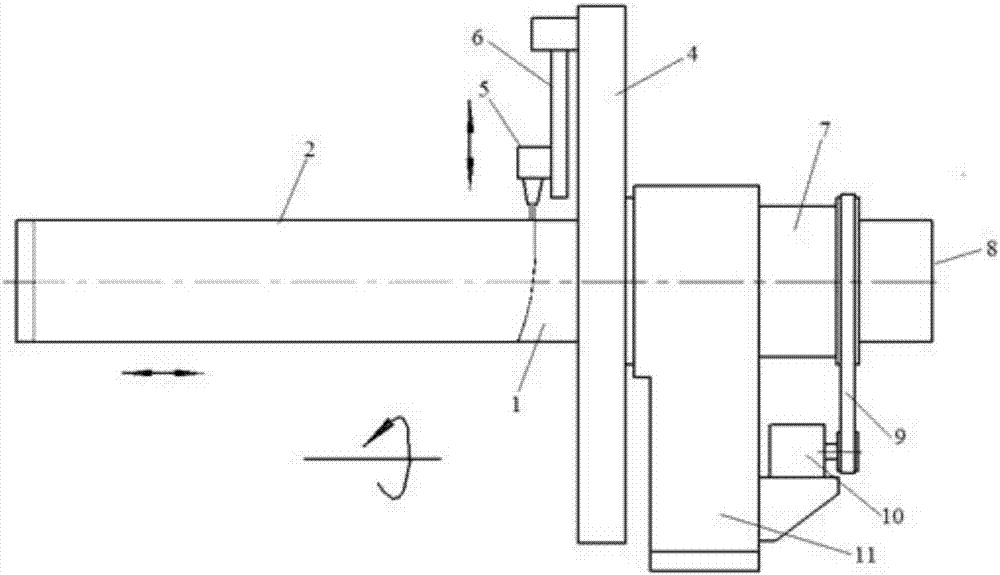

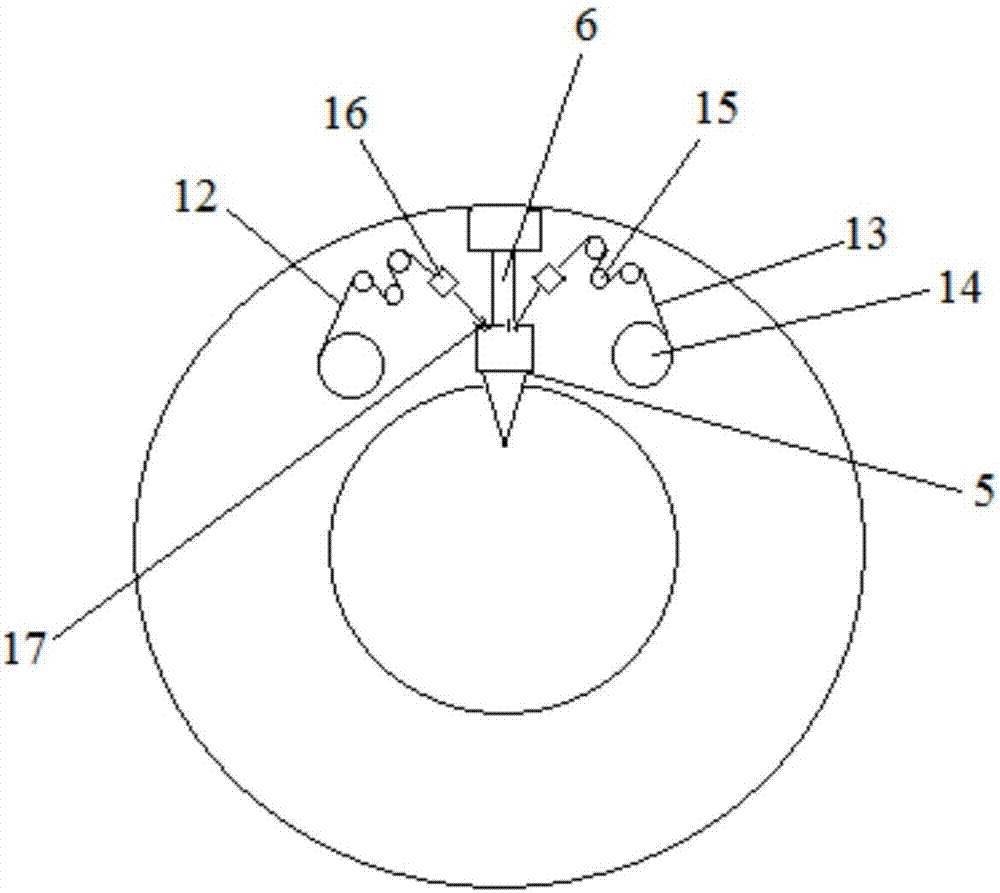

[0037] The inner lining of the pipeline is made of polyphenylene sulfide PPS; the fiber in the reinforcement layer is glass fiber, and the resin is polypropylene PP; the outer protective layer is high-density polyethylene HDPE. The thickness of the three structural layers from inside to outside is 40mm, 100mm, 30mm, and the inner diameter of the pipe is 1200mm.

[0038] Basic parameter setting: Extrusion temperature I is 300-320°C; printer head temperature is 180-200°C; extrusion temperature II is 200-220°C.

Embodiment 2

[0040] The inner lining layer of the pipeline is made of polyvinylidene fluoride PVDF modified resin; the fiber in the reinforcement layer is aramid fiber, and the resin is polypropylene PP; the outer protective layer is high-density polyethylene HDPE. The thickness of the three structural layers from inside to outside is 35mm, 90mm, 20mm, and the inner diameter of the pipe is 1400mm.

[0041] Basic parameter setting: extrusion temperature I is 220-240°C, printer head temperature is 180-200°C; extrusion temperature II is 200-220°C.

Embodiment 3

[0043] The inner lining layer of the pipeline is made of polyetheretherketone PEEK; the fiber in the reinforcement layer is carbon fiber, the resin is polypropylene PP; the outer protective layer is high-density polyethylene HDPE. The thickness of the three structural layers from inside to outside is 30mm, 100mm, 20mm, and the inner diameter of the pipe is 1200mm.

[0044] Basic parameter setting: Extrusion temperature I is 350-365°C; printer head temperature is 180-200°C, extrusion temperature II is 200-220°C

[0045] According to the pipeline structure parameters listed in Examples 1-3 and the main technical parameters of the 3D printing process, long-distance pipelines made of thermoplastic composite materials were manufactured.

[0046] Compared with the traditional extrusion molding manufacturing process, the present invention has obvious advantages such as simple operation and higher molding accuracy, and realizes the molding integration of thermoplastic resin material a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com