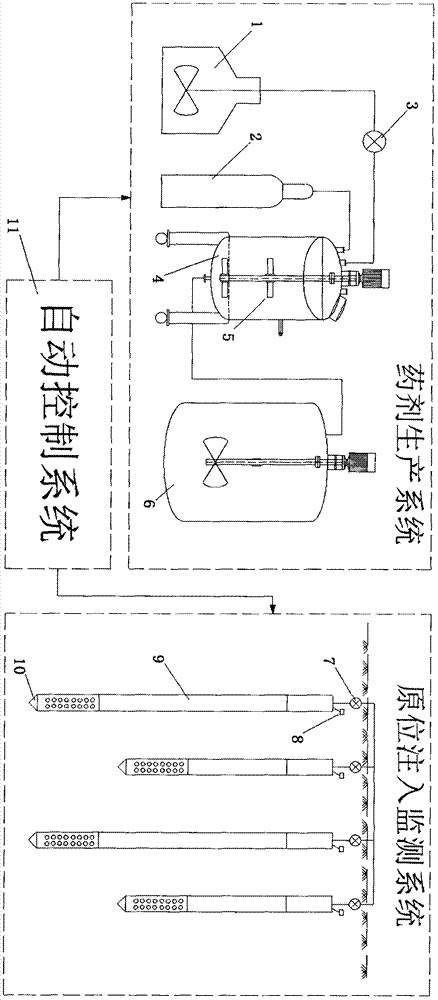

Nano-iron chemical preparing and in-situ injecting synchronous integrated equipment

A technology for injecting synchronous and nano-iron, which is applied in the direction of nanotechnology, control/adjustment process, chemical instruments and methods, etc., can solve the problems of long storage and transportation time, inactivation and unevenness of nano-iron agents, and achieve efficient production and high efficiency Repair, avoid agglomeration and inactivation, increase production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] For the point source pollution site of an abandoned electroplating factory, there is groundwater pollution with a hexavalent chromium concentration of 2mg / L, and the total amount of groundwater is 60m 3 , for the groundwater of the polluted site, 400L of nano-iron medicament with a concentration of 5mg / L was prepared by using the invented equipment, and the in-situ medicament injection and later monitoring were carried out. The monitoring results showed that the concentration of hexavalent chromium continued to decrease, and finally dropped to 0.05mg / L Below L, the groundwater quality standard is met.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com