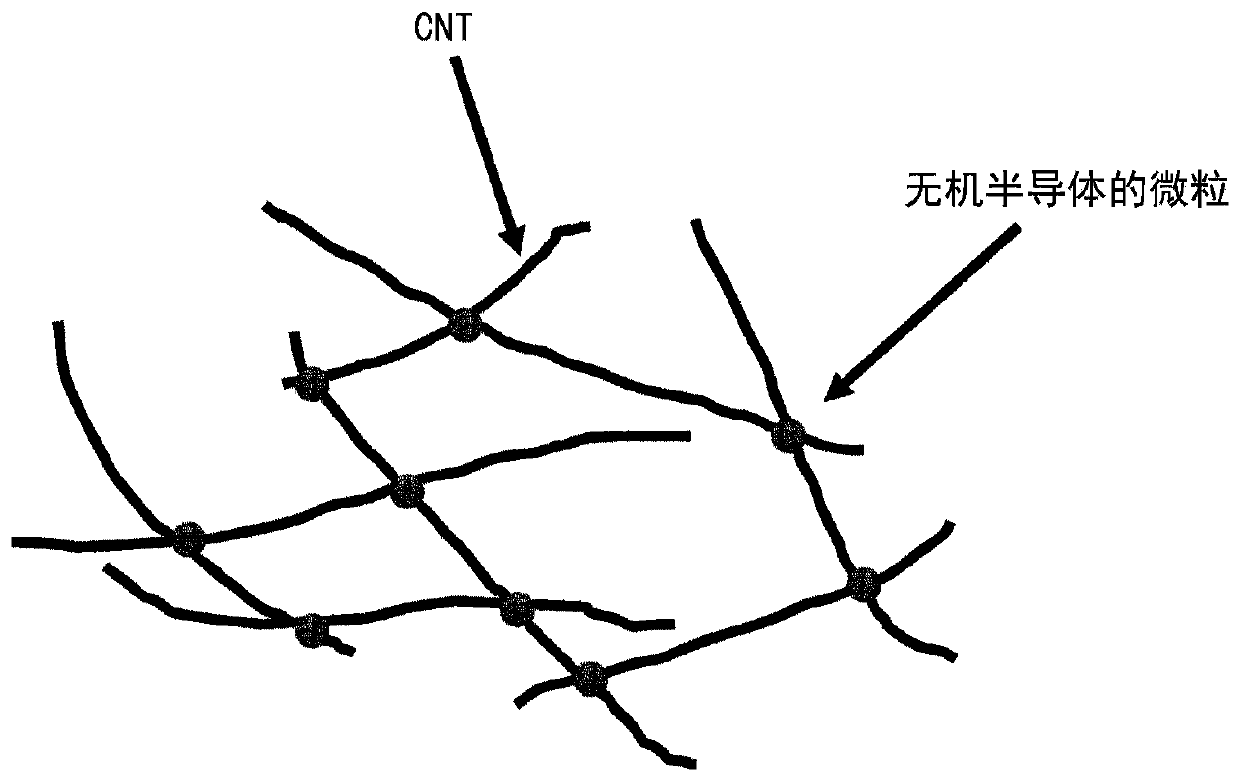

Carbon nanotube composite film and method for manufacturing same

A carbon nanotube composite, carbon nanotube technology, applied in the directions of carbon nanotubes, nanocarbons, nanotechnology, etc., can solve the problems of difficulty in obtaining low film resistance, poor mobility, hindering the absorption of conductive polymer dispersants, etc. Achieve smooth electrical conduction, excellent durability, and improve electrical conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-A

[0118] 2 g of hydroxypropyl cellulose (HPC) was dissolved in 40 ml of ethanol, followed by adding 10 mg of SWNT and mixing. After the liquid mixture was dispersed by ultrasonic treatment, centrifugation was performed at a rotation speed of 45000 rpm. The supernatant after centrifugation was used as a dispersion.

[0119] The dispersion solution was formed into a film by moving the doctor blade at a predetermined speed on the glass substrate by the doctor blade method. After standing at room temperature for 10 minutes to slightly dry the solvent, it was completely dried on a hot plate (100° C.) to obtain a CNT-containing film.

[0120] Next, according to the method described in Patent Document 5 or Non-Patent Document 3, pulsed light sintering was performed on the CNT-containing film obtained as described above to remove hydroxypropyl cellulose (HPC) as a matrix. Here, each irradiation time is 300 μS, the irradiation period is 1 Hz, and the peak irradiation intensity is 6 kW / ...

Embodiment 1-B

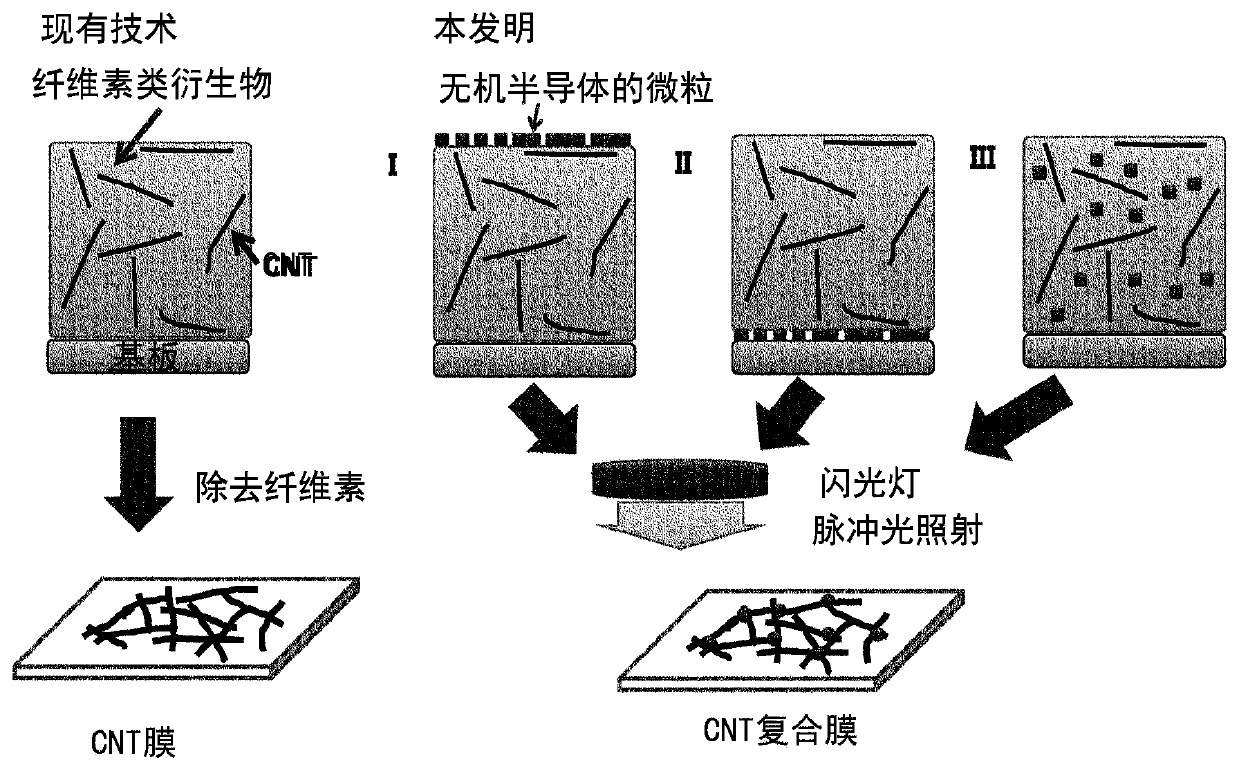

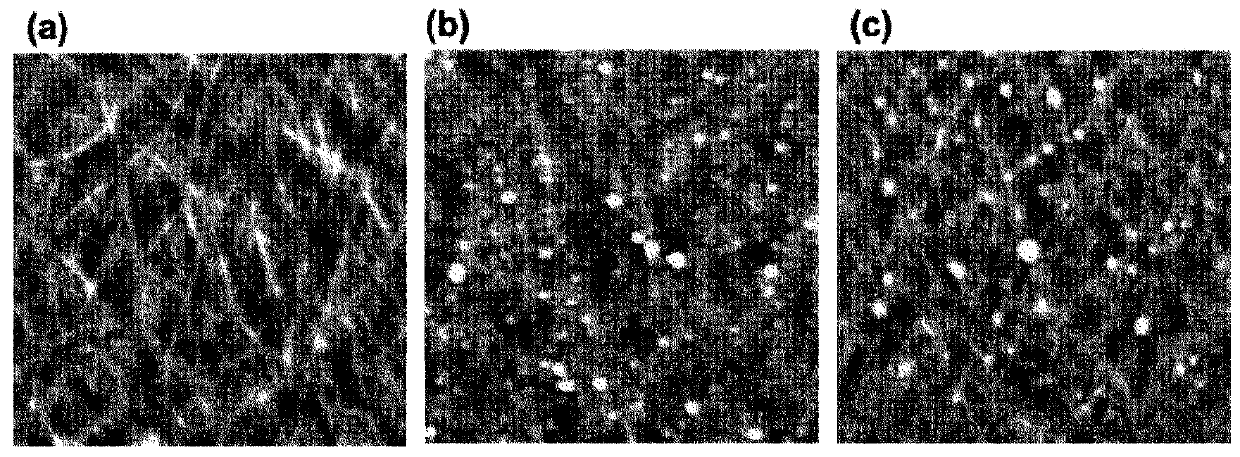

[0126] In this example, an inorganic semiconductor was coated and formed on the CNT conductive film after removal of the non-conductive matrix, and photo-sintering was performed with a flash lamp to move the inorganic semiconductor particles to the connection points of the CNTs.

[0127] After performing pulse light sintering on the CNT-containing film obtained as described in the 2nd line to the 8th line on the 12th page of the above-mentioned application specification, it is washed with 2-propanol and water to completely remove hydroxypropyl cellulose (HPC ), to obtain a CNT conductive film. A 0.05 mol / L acetonitrile solution of cuprous iodide was spin-coated on the CNT conductive film to laminate cuprous iodide, and then irradiated with a xenon flash lamp to perform photo-sintering. The sheet resistance of the obtained CNT composite film was 80 Ω / □, and the transmittance at 550 nm was about 80% (relative value when the transmittance of the glass substrate was 100%). This h...

Embodiment 1-C

[0129] In this example, cuprous bromide was used instead of cuprous iodide (Example 1-B), and a transparent conductive film was produced.

[0130] After performing pulse light sintering on the CNT-containing film obtained as described in the 2nd line to the 8th line on the 12th page of the above-mentioned application specification, it is washed with 2-propanol and water to completely remove hydroxypropyl cellulose (HPC ), to obtain a CNT conductive film. A 0.05 mol / L cuprous bromide acetonitrile solution was spin-coated on the CNT conductive film, and after the cuprous bromide was stacked, a xenon flash lamp was irradiated for photo-sintering. The sheet resistance of the obtained CNT composite film was 80 Ω / □, and the transmittance at 550 nm was about 80% (relative value when the transmittance of the glass substrate was 100%). This has sufficient conductivity for use as a transparent electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com