Room temperature nitrogen dioxide sensor preparation method based on reduced graphene-semiconductor

A nitrogen dioxide and semiconductor technology, which is applied in the field of preparation of room temperature nitrogen dioxide sensors based on reduced graphene-semiconductor, can solve the problems of increasing detection safety risk, slow response and recovery speed, and increasing sensor power consumption, and achieves multi-NO2 Effects of molecular adsorption sites, fast response and recovery rates, and fast electron transport rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

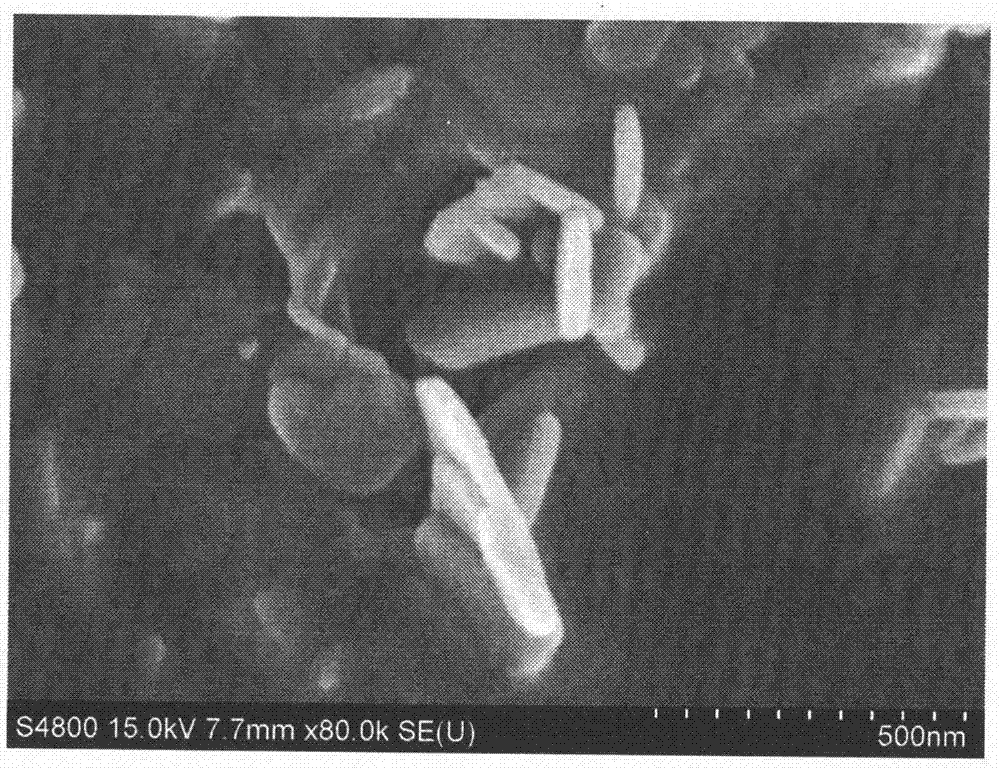

Embodiment 1

[0029] 1. Mix 2.0g graphite and 1.0g NaNO 3 Added to 46ml concentrated H under ice bath condition 2 SO 4 and stir for 1h

[0030] 2. Then add 6g KMnO 4 Add to the above mixture, and stir for 2h under ice bath conditions, then transfer to a constant temperature water bath at 38°C

[0031] 3. Then add 160ml deionized water to the above mixture and control the temperature at 95°C for 0.5h

[0032] 4. Then add 120ml deionized water to the above mixed solution and terminate the reaction

[0033] 5. Then add 30ml of 30% H to the above mixed solution 2 o 2 Reaction 30min

[0034] 6. Then add 30ml of 5% HCl, and wash with a centrifuge until neutral to prepare a suspension of graphene oxide

[0035] 7. Weigh 1.89g of zinc nitrate powder and dissolve it in 6ml of deionized water, and use a magnetic stirrer or other stirring device to obtain a uniform solution

[0036] 8. Then add 6ml of the previously prepared graphene oxide (GO) suspension and 6g of urea powder to the above mi...

Embodiment 2

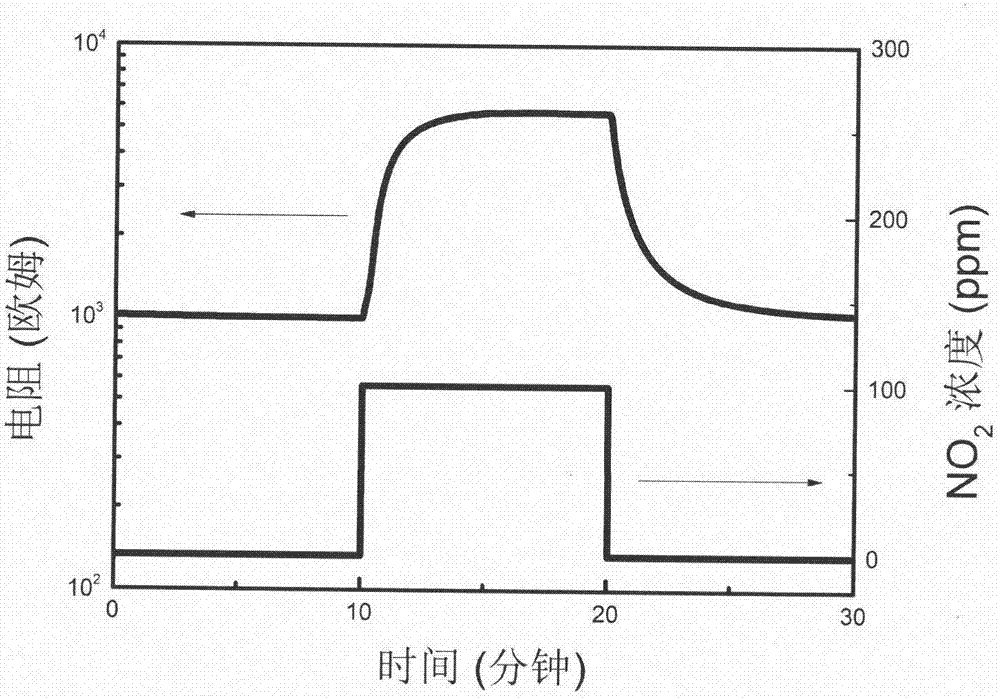

[0047] The difference between this example and Example 1 is that in step 7, 2.32g of crystalline tungsten hexachloride is weighed and dissolved in 5ml of absolute ethanol, and a uniform solution is obtained by magnetic stirring; 5ml of GO suspension and 5g of urea powder prepared above are used to obtain a homogeneous mixture using a high-speed stirrer or other stirring devices; in step 9, the mixture obtained above is transferred to a stainless steel autoclave with a Teflon substrate, and then the reaction The kettle was placed in an oven and kept at 180°C for 3 hours; in step 10, the reacted suspension was washed with water and ethanol in a centrifuge several times and dried in air to obtain rGO@WO 3 powder; in step 17, coating against 80ppm NO 2 , the sensitivity of the sensor is 13.82 respectively.

Embodiment 3

[0049] The difference between this embodiment and embodiment 1 is: take by weighing 1.56g crystal potassium stannate K in step 7 2 SnO 3 Dissolve in 5ml of deionized water, and use magnetic stirring to obtain a homogeneous solution; in step 8, add the GO suspension 5ml and urea powder 5g prepared above to the above mixture, and use a high-speed stirrer or other stirring devices to obtain a homogeneous mixture; In 9, the mixture obtained above was transferred to a stainless steel autoclave with a Teflon substrate, and then the reactor was put into an oven and kept at 240 degrees for 4h; in step 10, the reacted suspension was mixed with water and ethanol in Rinse multiple times in a centrifuge and dry in air to obtain rGO@SnO 2 powder; in step 17, coating against 15ppm NO 2 , the sensitivity of the sensor is 5.63 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com