Ultrasonic punching device for blast furnace slag

An ultrasonic and blast furnace slag technology, applied in the field of blast furnace slag ultrasonic punching device, can solve the problems of insufficient heat exchange speed, uneven particle size of water slag, increase equipment load, etc. The particle size of water slag and the effect of reducing equipment load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

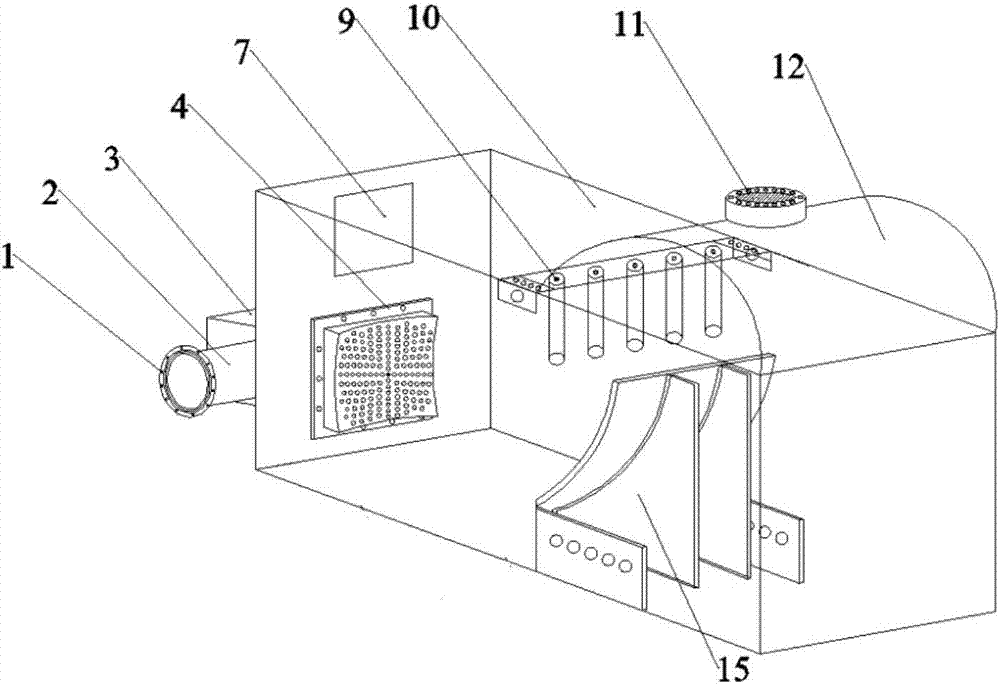

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] refer to figure 1 , 2 , The main body 3 of the flushing tank is installed below the slag inlet 7. There is a water inlet pipe 2 on one side of the main body of the water tank. The water inlet pipe 2 is connected to the external water pipe through the flange disc 1 to save floor space and reduce space occupation.

[0020] The main body of the flushing tank is connected with the punching orifice plate 6 through the flange plate 4. There is a punching nozzle 5 on the punching orifice plate 6. Evenly distributed in the radial direction to achieve the effect of converging the slag flushing stream and enhancing the punching efficiency.

[0021] A slag flushing ditch 16 is formed between the left and right retaining walls 10 of the main body of the flushing device; the first half of the slag flushing ditch is an inclined section, and the second half is a gentle secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com