Conditioner for reducing ammonia volatilization during chicken manure composting and preparation method of conditioner

A technology of ammonia volatilization and conditioning agent, applied in the direction of phosphate fertilizer, application, organic fertilizer, etc., can solve the problems of large amount of application, difficult to obtain, difficult to apply, etc., achieve low cost, easy to control the process, and reduce the effect of ammonia volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

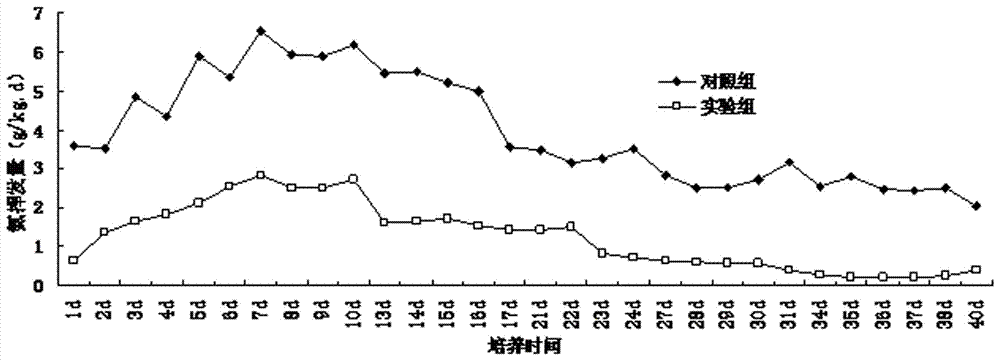

Image

Examples

Embodiment 1-5

[0032] Embodiment 1-5 is used to reduce the conditioning agent of ammonia volatilization in the chicken manure composting process

[0033] Embodiments 1-5 are respectively a conditioner for reducing ammonia volatilization in the chicken manure composting process, and the conditioner includes the components shown in the following table in parts by weight:

[0034] Table 1 Component list of conditioner used to reduce ammonia volatilization during chicken manure composting

[0035]

[0036] Mushroom residue is made of waste mushroom sticks after conventional mushroom production, that is, using straw, sawdust and other raw materials for edible fungus cultivation, and the culture medium residue after harvest is commonly known as edible mushroom cultivation waste, mushroom residue or residue The fungus residue is rich in amino acids, fungal polysaccharides and trace elements such as Fe, Ca, Zn, Mg, etc., which can adjust the pH value;

Embodiment 6

[0044] Example 6 The preparation method of the conditioner used to reduce the volatilization of ammonia in the chicken manure composting process

[0045] This embodiment is the preparation method of five kinds of conditioners used to reduce ammonia volatilization in the chicken manure composting process provided by Embodiment 1-5, and the method includes the following steps carried out in sequence:

[0046] (1) Dry the fungus sticks, and use a crusher to crush them into 1-3cm fungus residue debris;

[0047] (2) Put the formula amount of fungus residue and formula amount of peat into a dryer to dry, and after drying, use a pulverizer to pulverize, pass through a sieve with a diameter of 5mm and mix well to obtain a mixture A;

[0048] (3) Put the zeolite into a muffle furnace for calcination, the calcination temperature is 200-400°C, the calcination time is 4h, after calcination, grind it finely, and pass through a 200 mesh sieve to obtain the modified zeolite powder; take the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com