Process for preparing manganese sulfate by high-temperature crystallization method and automatic continuous production device

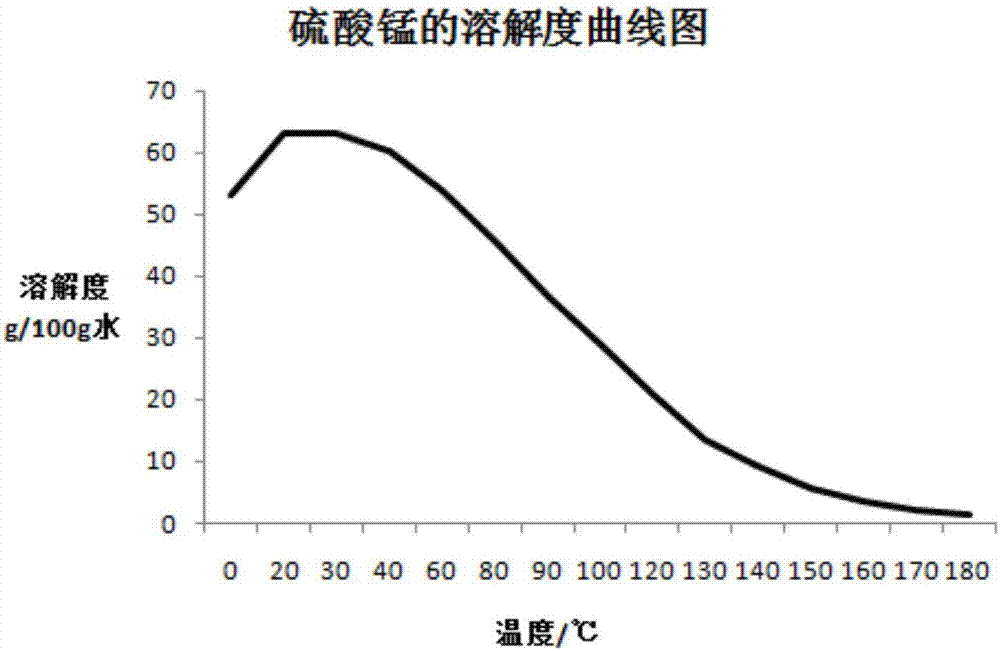

A technology of high-temperature crystallization and production equipment, applied in the direction of manganese sulfate, etc., can solve the problems of high energy consumption, high labor intensity, and low degree of automation of manganese sulfate, and achieve the effects of reducing energy consumption, reducing labor intensity, and advanced production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

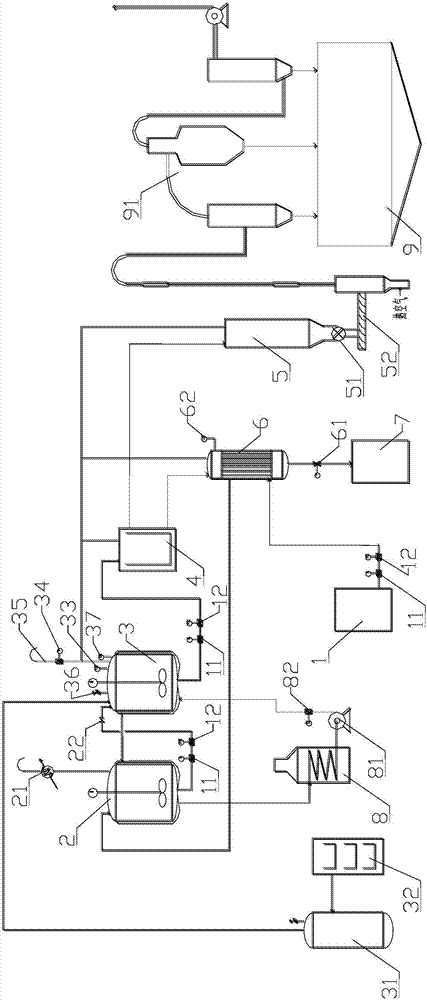

[0022] The technology for preparing manganese sulfate by high-temperature crystallization method may further comprise the steps:

[0023] The first step, the manganese sulfate solution (wherein the concentration is 350 grams per liter) after the impurity removal and purification in the liquid storage tank, each adds 2000 liters of manganese sulfate to the preheating kettle of 3000 liters and the high-temperature crystallization kettle of 3000 liters by metering pump solution, open the agitator of the preheating kettle and the high-temperature crystallization kettle, and feed compressed air into the high-temperature crystallization kettle, so that the internal pressure of the high-temperature crystallization kettle, the automatic discharge centrifuge, the mother liquor heat exchanger, and the silo are all maintained at 0.8 MPa, and then turn on the circulation pump of the heat transfer oil, and the temperature of the heat transfer oil is controlled at about 250°C.

[0024] In t...

Embodiment 2

[0028] The technology for preparing manganese sulfate by high-temperature crystallization method may further comprise the steps:

[0029] The first step, the manganese sulfate solution (wherein the concentration is 360 grams per liter) after the impurity removal and purification in the liquid storage tank, each adds 3000 liters of manganese sulfate to the preheating kettle of 4000 liters and the high temperature crystallization kettle of 4000 liters by metering pump solution, open the agitator of the preheating kettle and the high-temperature crystallization kettle, and feed compressed air into the high-temperature crystallization kettle, so that the internal pressure of the high-temperature crystallization kettle, the automatic discharge centrifuge, the mother liquor heat exchanger, and the silo are all maintained at 0.8 MPa, and then turn on the circulation pump of the heat transfer oil, and the temperature of the heat transfer oil is controlled at about 250°C.

[0030] In t...

Embodiment 3

[0034] The technology for preparing manganese sulfate by high-temperature crystallization method may further comprise the steps:

[0035] The first step, the manganese sulfate solution (wherein the concentration is 340 grams per liter) after the impurity removal and purification in the liquid storage tank, respectively add 3800 liters of manganese sulfate to the preheating kettle of 5000 liters and the high temperature crystallization kettle of 5000 liters by metering pump solution, open the agitator of the preheating kettle and the high-temperature crystallization kettle, and feed compressed air into the high-temperature crystallization kettle, so that the internal pressure of the high-temperature crystallization kettle, the automatic discharge centrifuge, the mother liquor heat exchanger, and the silo are all maintained at 0.8 MPa, and then turn on the circulation pump of the heat transfer oil, and the temperature of the heat transfer oil is controlled at about 250°C.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com