A method for preparing zeolite molecular sieves from opal attapulgite clay

A technology of attapulgite clay and zeolite molecular sieve, applied in chemical instruments and methods, crystalline aluminosilicate zeolite, A-type crystalline aluminum silicate zeolite, etc., can solve problems affecting the mine environment and the economic benefits of mining enterprises, etc. To achieve the effect of solving the utilization problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present embodiment prepares the zeolite molecular sieve according to the following steps:

[0024] A. Store the opal attapulgite clay, after 6 months of natural dry and wet weathering, pass through a 2mm sieve, and the sieve is the opal material, which is used for the synthesis of zeolite molecular sieves;

[0025] B. Stockpile the opal material obtained by screening, soak the material at 70°C for 2 hours with hydrochloric acid with a mass concentration of 10%, and dissolve the impurity components dolomite and attapulgite therein; after the soaking is completed, discharge the waste liquid and obtain the solid After washing with water, draining and grinding through a 200-mesh sieve, the opal powder is obtained;

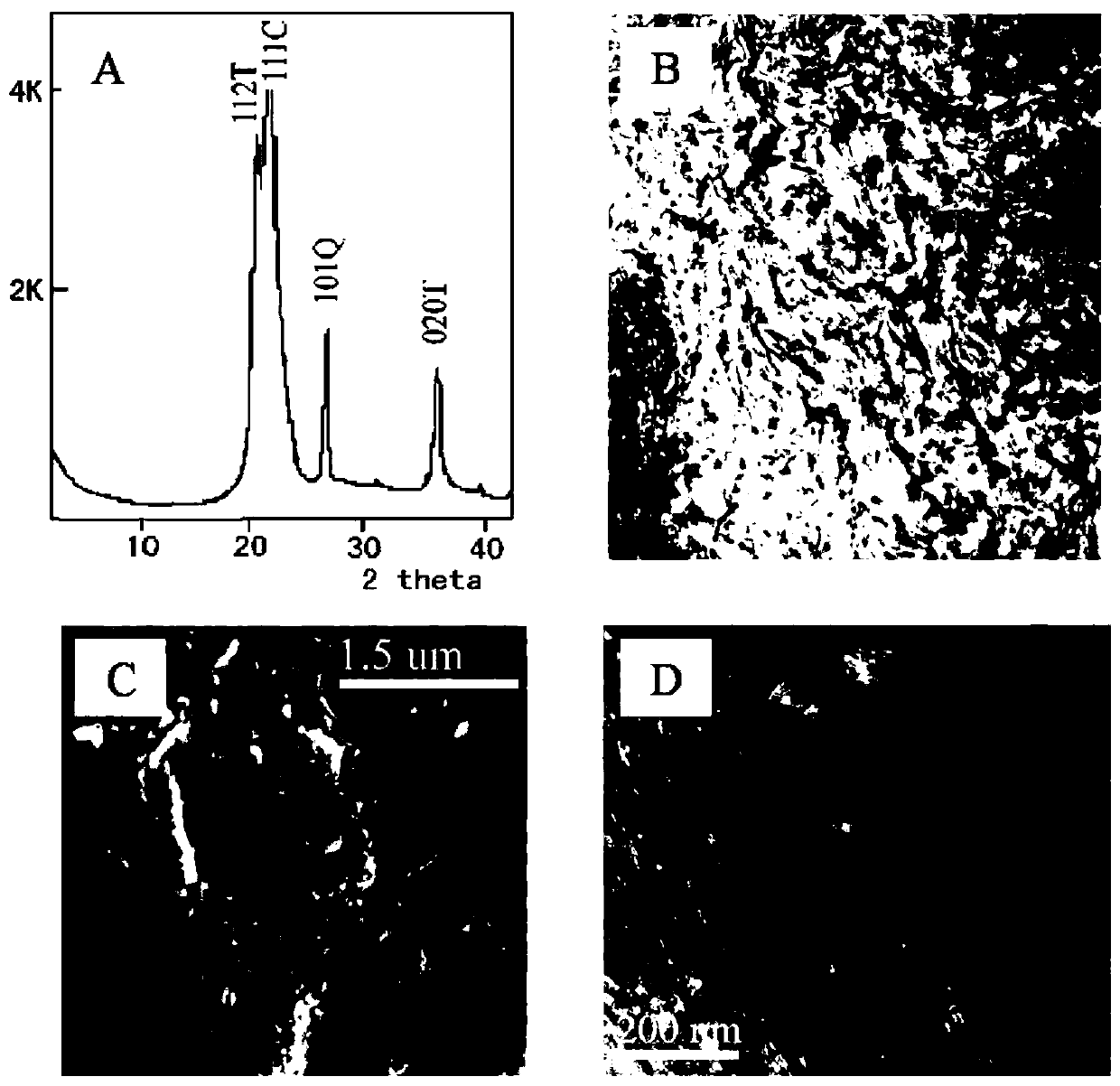

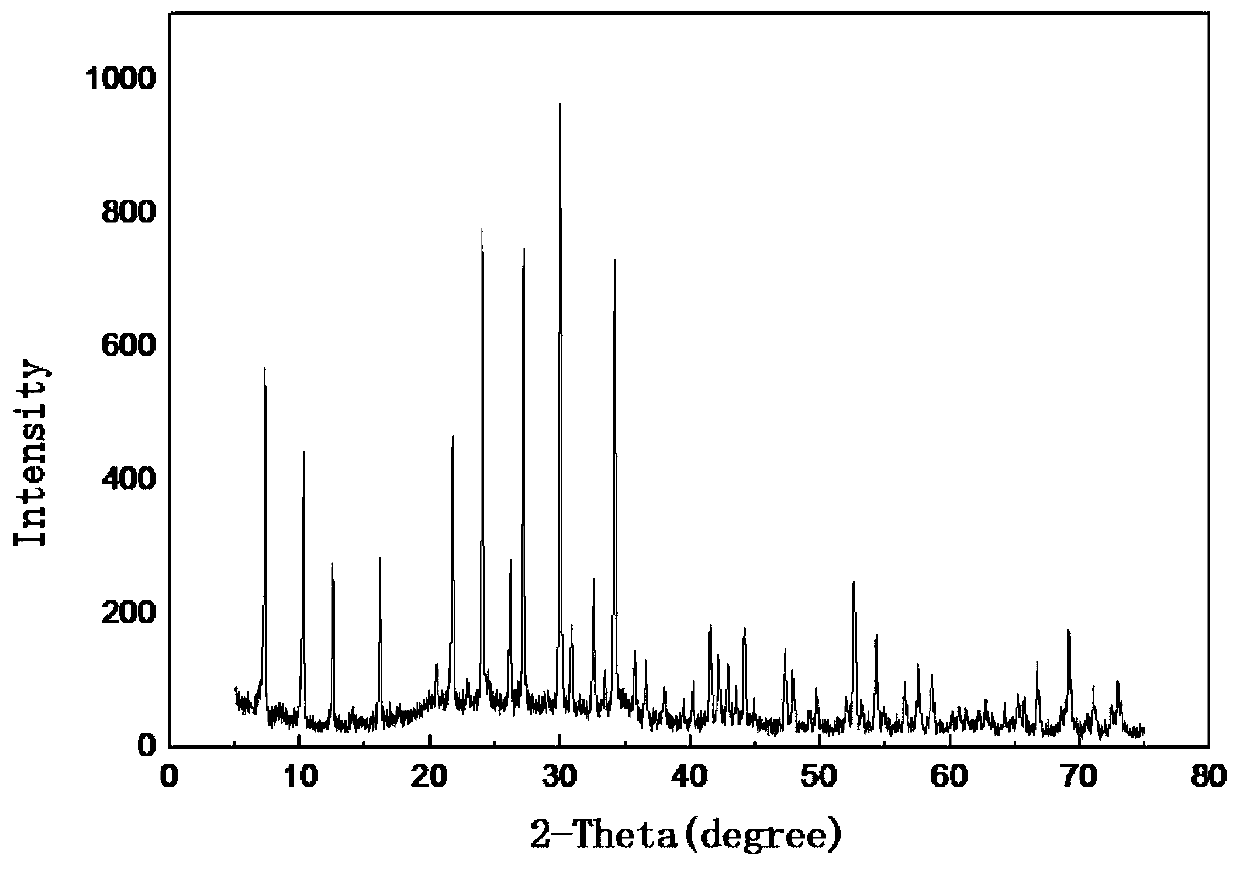

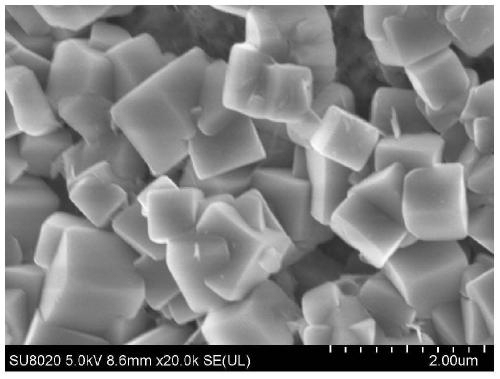

[0026] C. Dissolve 1.82g NaOH in 15mL deionized water, add it to the polytetrachlorethylene lined reactor, add 3g of opal powder, and take 3.6g NaAlO 2 Dissolve in 17mL water to make NaAlO 2 solution, then the NaAlO 2 Add the solution into the reaction ke...

Embodiment 2

[0031] The present embodiment prepares the zeolite molecular sieve according to the following steps:

[0032] A. Store the opal attapulgite clay, after 3 months of natural dry-wet alternating weathering, pass through a 2mm sieve, and the material on the sieve is the opal material, which is used for the synthesis of zeolite molecular sieves;

[0033] B, stockpile the opal material obtained by screening, soak the material for 3 hours with hydrochloric acid with a mass concentration of 15%, dissolve the impurity components dolomite and attapulgite therein; after soaking is completed, the waste liquid is discharged, and the gained solid is washed with water and drain After drying, grind through a 200-mesh sieve to obtain opal powder;

[0034] C. Mix opal powder with sodium metaaluminate, sodium hydroxide and water according to the molar ratio of silicon to aluminum is 2:1, the molar ratio of alkali to silicon is 1.5:1, and the molar ratio of water to sodium is 60:1. React in a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com