Stabilizing agent for treating waste incineration fly ash, preparation method and application thereof

A waste incineration fly ash and stabilization technology, which is applied in the direction of chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problem that the long-term safety requirements of hazardous waste treatment cannot be met, the removal effect of heavy metal ions is not ideal, Difficult sources of raw materials and other issues, to achieve the effect of excellent operability, wide application range, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

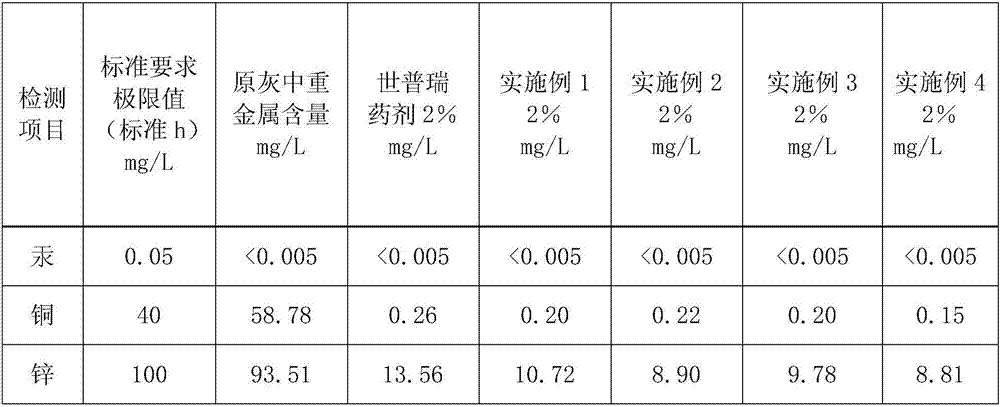

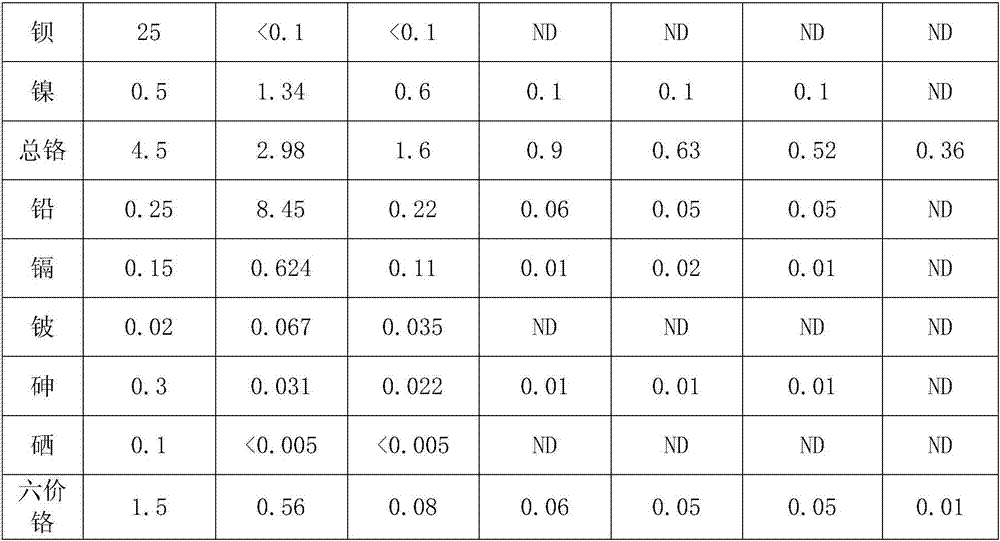

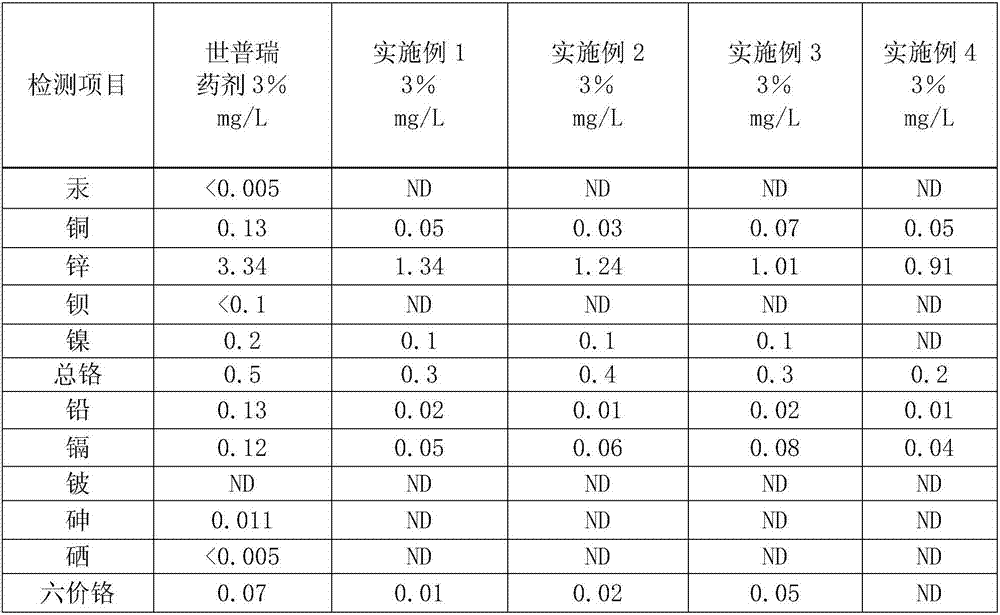

Examples

Embodiment 1

[0023] In the first step, add 150Kg of pure water to the reaction kettle, under stirring, the rotation speed is 70 rpm, slowly add 200kg of sodium ethylthiocarbamate required for production into the reaction kettle, and dissolve completely after stirring for 30 minutes After that, the intermediate product a is obtained.

[0024] In the second step, in the dissolving tank, 150Kg of water was added, and 200Kg of dimercaptopropanol was added for dissolution to obtain a uniform liquid b.

[0025] In the third step, the products a and b are mixed evenly in the reactor.

[0026] The fourth step is to add 295Kg of potassium dihydrogen phosphate and 5Kg of methyl cellulose to the reaction kettle in sequence at room temperature of 25°C, stir and dissolve, and obtain the product after filtration.

Embodiment 2

[0028] The first step, add 130Kg of pure water in reactor, under stirring, rotating speed is 80 rev / mins, 300kg of potassium dimethyl thiocarbamate required for production is slowly added in reactor, after stirring for 30 minutes, After complete dissolution, intermediate a was obtained.

[0029] In the second step, in the dissolving tank, 130Kg of water was added, and 100Kg of dimercaptopropanol was added for dissolution to obtain a uniform liquid b.

[0030] In the third step, the products a and b are mixed evenly in the reactor.

[0031] The fourth step is to add 290Kg of potassium dihydrogen phosphate and 50Kg of dimethyl cellulose to the reaction kettle in sequence at room temperature of 25°C, stir and dissolve, and obtain the product after filtration.

Embodiment 3

[0033] The first step, add 140Kg of pure water in the reaction kettle, under stirring, the rotating speed is 70 rpm, slowly add 300kg of sodium diethylthiocarbamate required for production into the reaction kettle, after stirring for 30 minutes, completely After dissolution, intermediate a is obtained.

[0034] In the second step, in the dissolving tank, 140Kg of water was added, and 100Kg of dimercaptopropanol was added for dissolution to obtain a uniform liquid b.

[0035] In the third step, the products a and b are mixed evenly in the reactor.

[0036] The fourth step is to add 300Kg of sodium dihydrogen phosphate and 20Kg of methyl cellulose to the reactor at normal temperature of 25°C, stir and dissolve, and filter to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com