High-capacitance polyindole nitrogen-doped porous carbon material and preparation method thereof

A technology of nitrogen-doped porous carbon and polybenzazole, which is applied in the manufacture of hybrid/electric double-layer capacitors and electrodes of hybrid capacitors, and can solve problems such as high cost, cumbersome process, and unfriendly environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

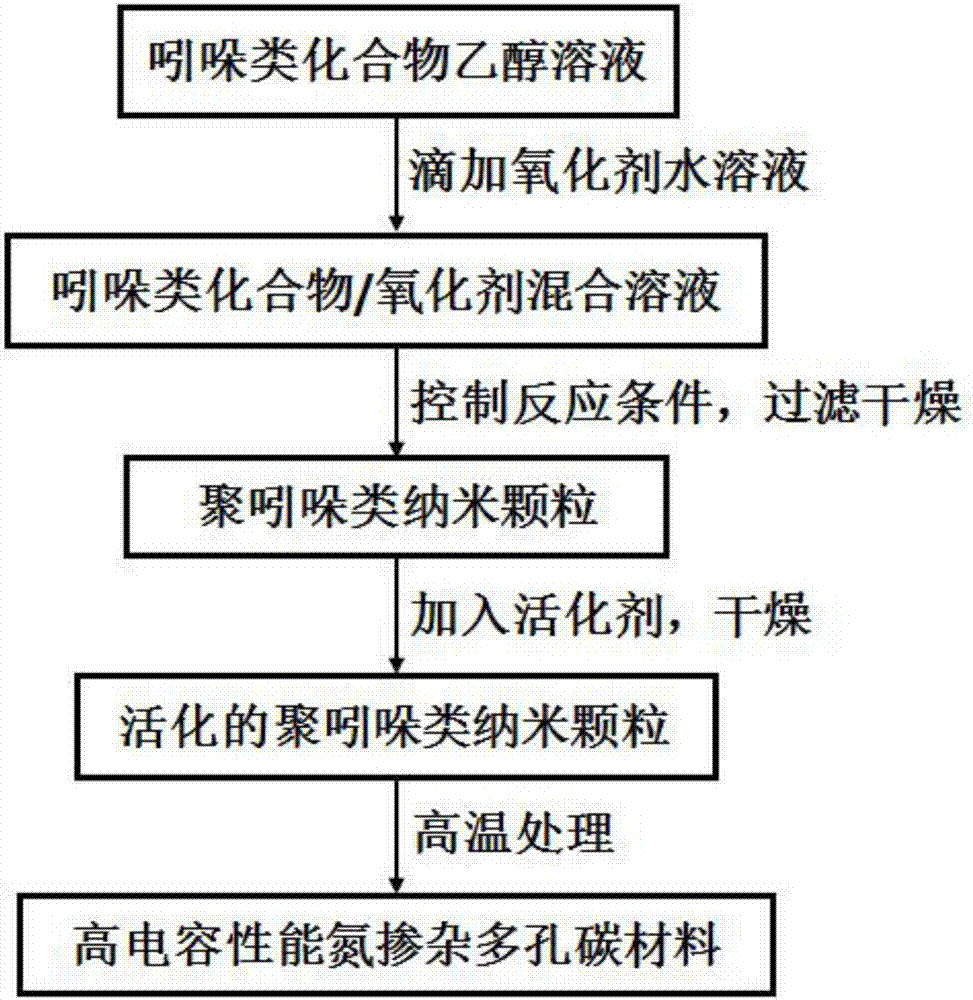

Method used

Image

Examples

Embodiment 1

[0029] The high-capacity polybenzazole nitrogen-doped porous carbon material is made of the following components by weight: 10 parts of indole, 50 parts of ammonium persulfate, 60 parts of potassium hydroxide, ethanol-water mixed solution (the mass of ethanol and aqueous solution The ratio is 0.2:1) 500 parts.

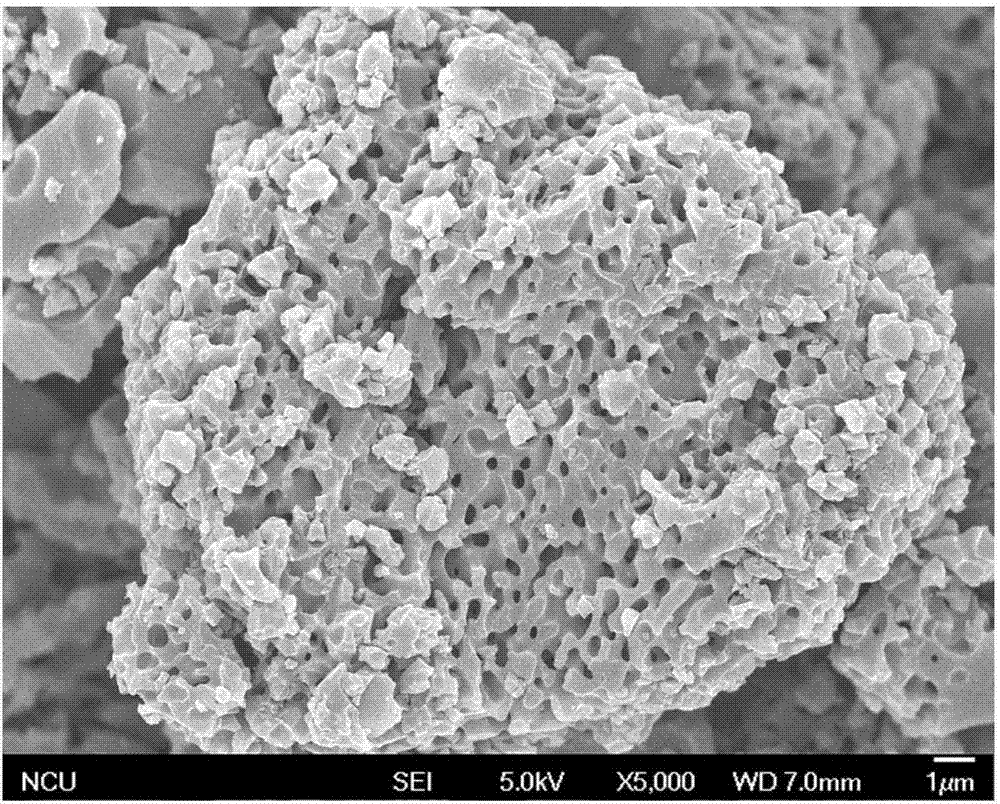

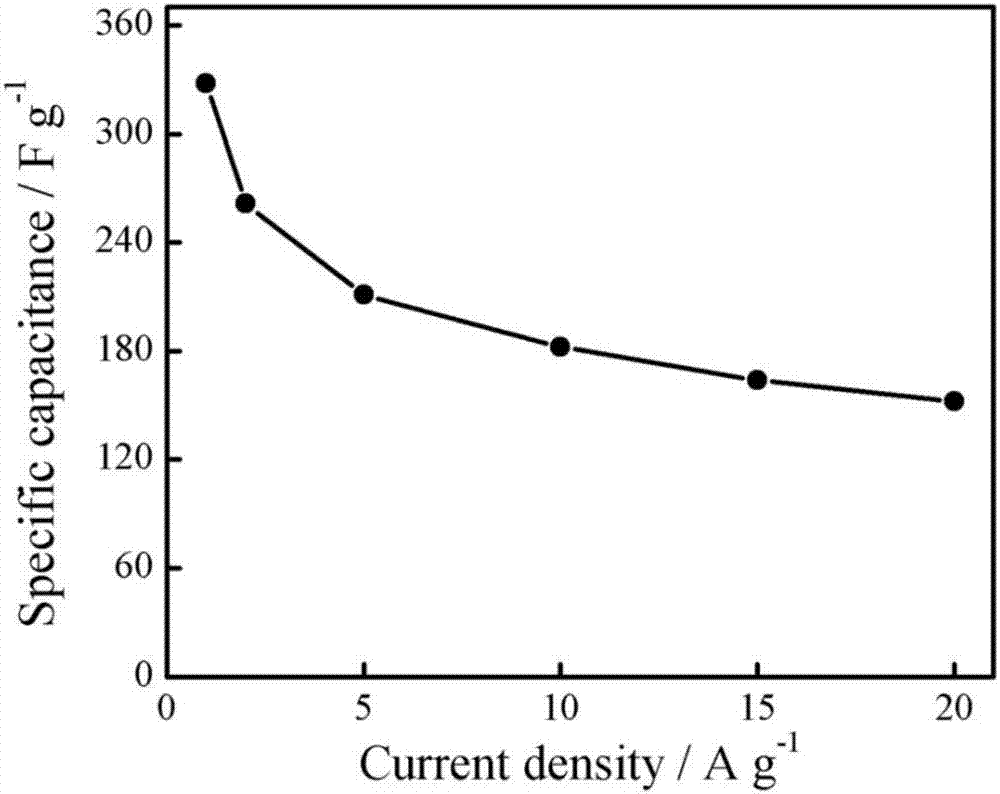

[0030] Depend on figure 2 As shown, the high-capacitance polybenzazole nitrogen-doped porous carbon material has a large pore size distribution, which is determined by image 3 As shown, the specific capacitance value of the nitrogen-doped porous carbon material is 330F / g at a current density of 1A / g, and when the current density increases to 20A / g, the specific capacitance value is 160F / g, by Figure 4 As shown, the nitrogen-doped porous carbon material has a stability of 87% under the condition of 1000 cycles.

Embodiment 2

[0032] The high-capacity polybenzazole nitrogen-doped porous carbon material is made of the following components in parts by weight: 10 parts of carboxyindole, 10 parts of aminoindole, 30 parts of copper perchlorate, 30 parts of potassium permanganate, hydrogen 150 parts of sodium oxide, 750 parts of dichloromethane water mixed solution (the mass ratio of dichloromethane to aqueous solution is 0.4:1).

[0033] It is determined that the capacitance value of the high-capacity polybenzazole nitrogen-doped porous carbon material is 332 F / g at a current density of 1 A / g, and the 1000-cycle stability reaches 91%.

Embodiment 3

[0035] High-capacity polybenzazole nitrogen-doped porous carbon material, made of the following components by weight: 15 parts of 5-nitroindole, 10 parts of aminoindole, 5 parts of cyanindole, and 45 parts of potassium iodate , 25 parts of potassium permanganate, 120 parts of potassium hydroxide, 30 parts of sodium carbonate, 30 parts of zinc chloride, 700 parts of isopropanol-water mixed solution (the mass ratio of isopropanol and aqueous solution is 0.3:1), acetonitrile aqueous solution (The mass ratio of acetonitrile to aqueous solution is 0.5:1) 300 parts.

[0036] It is determined that the capacitance value of the high-capacity polybenzazole nitrogen-doped porous carbon material is 389 F / g at a current density of 1 A / g, and the 1000-cycle stability reaches 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com