Nitrogen-doped porous carbon material as well as preparation method and application thereof

A nitrogen-doped porous carbon and carbonization technology is applied in the field of porous carbon materials, which can solve the problem that the catalytic performance of oxygen reduction needs to be improved, and achieve the effects of improving oxygen reduction performance, improving electrical conductivity and high specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

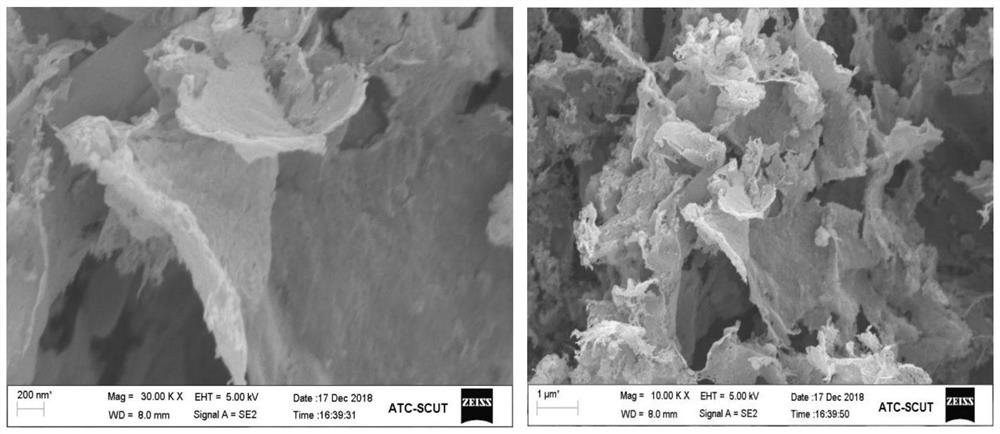

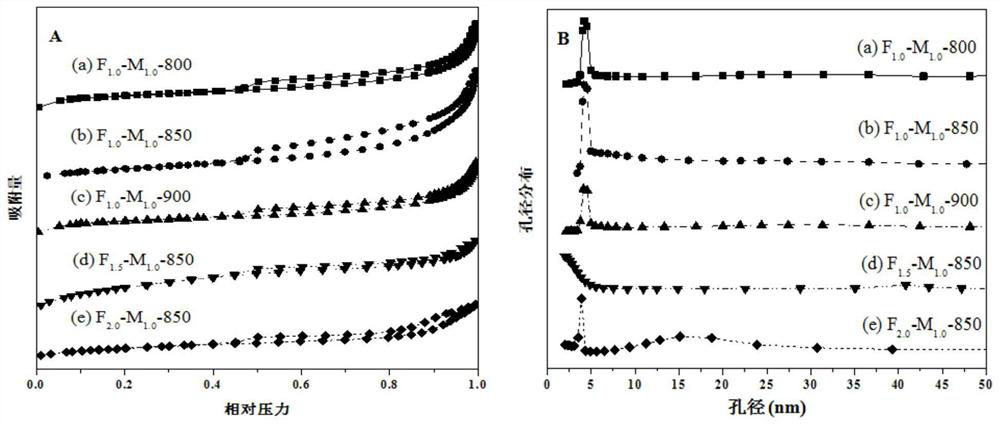

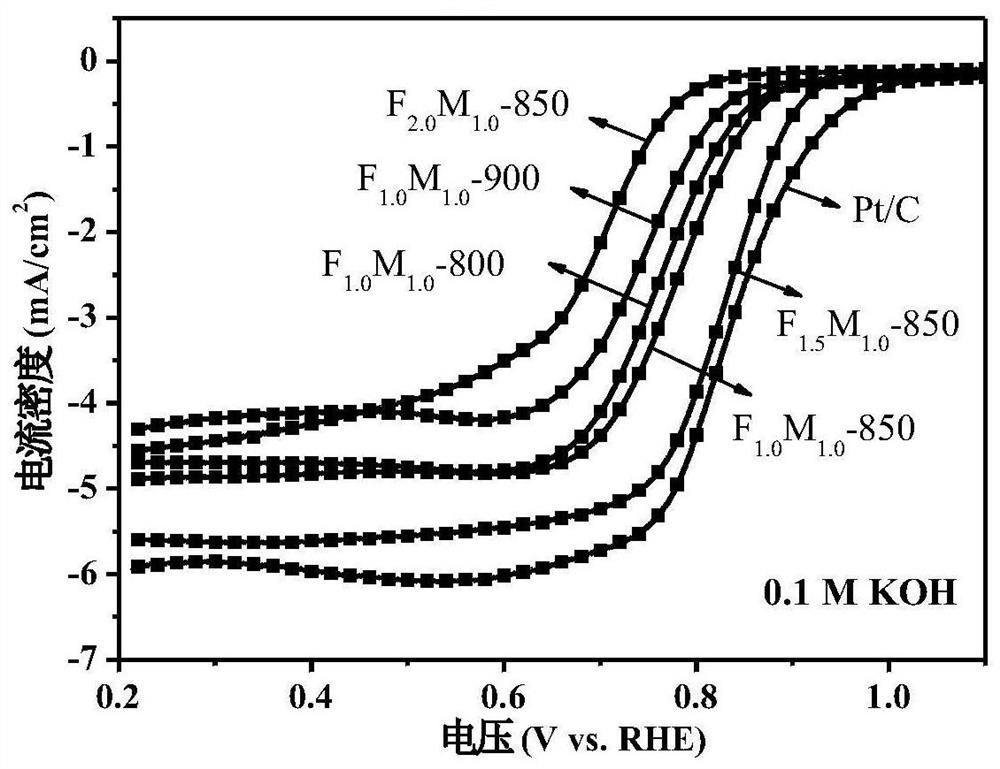

[0045] A nitrogen-doped porous carbon material (denoted as F 1 -M 1 -800, where, F 1 , M 1 They are respectively potassium ferrate and magnesium chloride hexahydrate, and the molar ratio of potassium ferrate and magnesium chloride hexahydrate is 1:1, and 800 is the high-temperature calcination temperature, and the preparation method of 800° C.) specifically includes the following steps:

[0046] Weigh 1.5g F127 (EO 106 PO 70 EO 106 ) was added to the ethanol-water solution prepared with 50mL water and 50mL ethanol, and after magnetic stirring for 10 minutes at 80°C in a water bath, 4.0g melamine, 2.0g MgCl 2 ·6H 2O, 1.95g potassium ferrate, continue stirring for 40 minutes, add 1.4g agarose, continue stirring for 2.5 hours, then pour into a culture dish to cool naturally to form a hydrogel; Cover the Petri dish with plastic wrap with small holes, and dry it at -50°C for 60 hours to obtain a white dry gel, which is transferred to a porcelain boat and placed in a tube fur...

Embodiment 2

[0049] A nitrogen-doped porous carbon material (denoted as F 1 -M 1 -850, where, F 1 , M 1 , 850 are respectively potassium ferrate and magnesium chloride hexahydrate, and the molar ratio of potassium ferrate and magnesium chloride hexahydrate is 1:1, 850 is the preparation method of choosing 850 ℃ for the high temperature calcination temperature), specifically comprising the following steps:

[0050] Weigh 2.8g of F127 and add it to the ethanol-water solution prepared with 120mL of water and 80mL of ethanol. After magnetically stirring for 15 minutes in a water bath at 78°C, add 8.4g of melamine and 4.0g of MgCl in sequence. 2 ·6H 2 O, 3.90g potassium ferrate, continue stirring for 30 minutes, add 2.4g agarose, continue stirring for 3 hours, then pour into the petri dish to cool naturally to form a hydrogel; Cover the petri dish with a plastic wrap with small holes, and dry it at -55°C for 72 hours to obtain a white dry gel, transfer it to a porcelain boat, and place it i...

Embodiment 3

[0053] A nitrogen-doped porous carbon material (denoted as F 1 -M 1 -900, of which, F 1 , M 1 The amount of potassium ferrate and magnesium chloride hexahydrate added to each 100mL ethanol-water solution is about 0.01mol, and 900 is the high-temperature calcination temperature of 900°C). The preparation method specifically includes the following steps:

[0054] Weigh 2.1g of F127 (Pluronic F127) and add it to the ethanol-water solution prepared with 80mL of water and 60mL of ethanol. After stirring magnetically for 10 minutes at 82°C in a water bath, add 6.3g of melamine and 2.8g of MgCl in sequence. 2 ·6H 2 O, 2.73g potassium ferrate, continue stirring for 30 minutes, add 1.82g agarose, continue stirring for 2 hours, then pour into a petri dish to cool naturally to form a hydrogel; Cover the petri dish with a plastic wrap with small holes, and dry it at -50°C for 48 hours to obtain a white dry gel, which is transferred to a porcelain boat and placed in a tube furnace from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com