Kitchen waste disposal system and method

A kitchen waste and treatment system technology, applied in waste treatment, solid waste removal, etc., can solve problems affecting the effect of resource utilization, etc., to overcome the lack of alkalinity and nutrients, ensure stable operation, and the technology is completely feasible Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

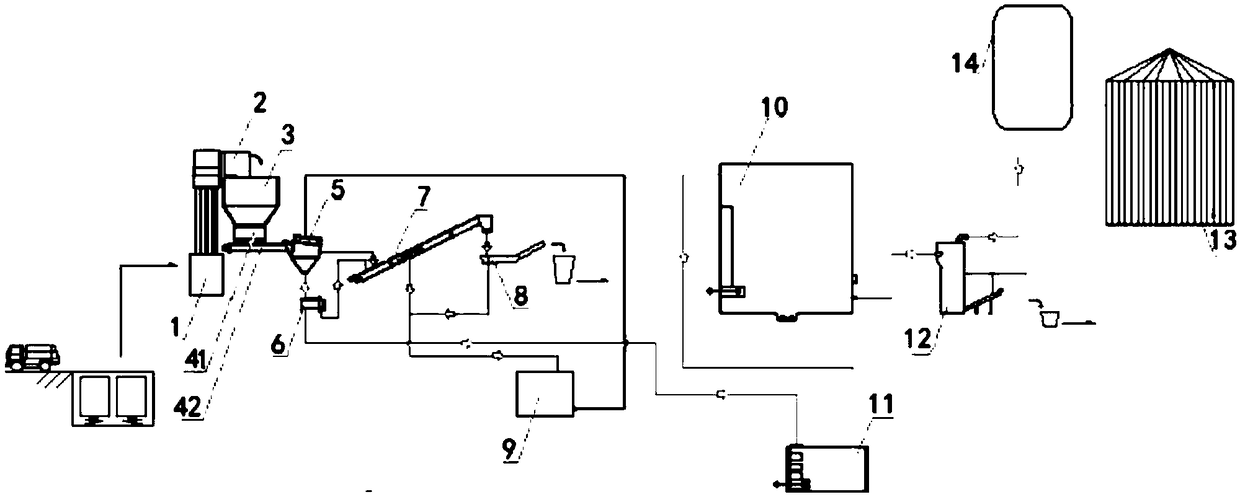

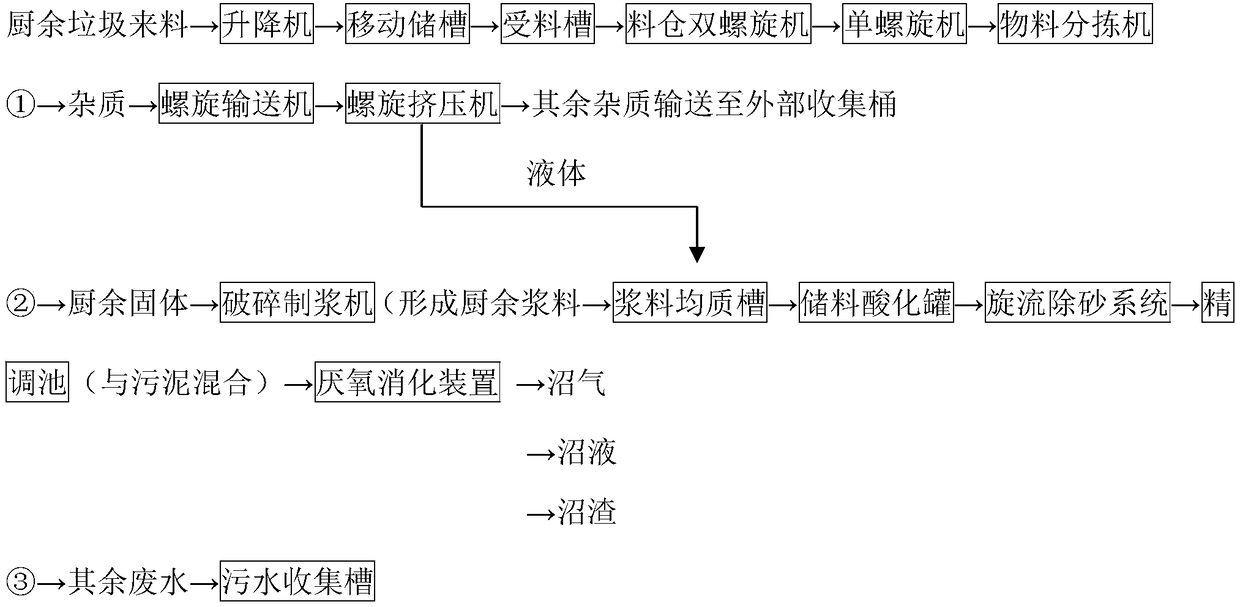

[0028]A kitchen waste treatment system: comprising a mobile storage tank 2 with an elevator 1, the lower part of the mobile storage tank 2 is provided with a receiving tank 3, and the bottom of the receiving tank 3 is sequentially provided with a double-screw machine 41 for a silo, a hopper list The screw machine 42, the outlet of the single screw machine 42 in the silo is connected to the material sorter 5, and the material sorter 5 separates impurities and kitchen waste solids, and is respectively connected to the screw conveyor 7 and the crushing and pulping machine 6; the crushing and pulping Machine 6 is sequentially connected to slurry homogenizing tank 11, material storage acidification tank 10, cyclone desanding system 12, fine adjustment tank 14, anaerobic digestion tank 13; screw conveyor 7 outlet is connected to screw extruder 8; screw extruder The pipeline of the separated liquid in the machine 8 is connected to the slurry homogenizing tank 11; the obtained impuriti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com