A kind of composite material, its preparation method and application

A technology of composite materials and carbon nanomaterials, which is applied in the field of composite materials and its preparation, can solve the problems of complex process, low nitrogen doping amount, low cathode oxygen reduction activity, etc., and achieve simple preparation process, increase nitrogen doping amount, Favorable effect for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Composite material provided by the invention, its preparation method, comprises the following steps:

[0035] (1) Mix melamine, concentrated acid and water, wherein the mass ratio of melamine to concentrated acid is 1:1 to 2:5, and the mass ratio of melamine to water is 1:25-1:30, at 70°C to 90°C heated to transparent to obtain a transparent solution; the concentrated acid is preferably the concentrated sulfuric acid, concentrated nitric acid or concentrated phosphoric acid that can coordinate with melamine, wherein the common concentration of concentrated sulfuric acid is 98%, and the common concentration of concentrated nitric acid is 65%. The common concentration of concentrated phosphoric acid is 85%;

[0036] (2) Add carbon nanomaterials and cobalt salts to the transparent solution prepared in step (1) and mix evenly, wherein the mass ratio of carbon nanomaterials and melamine is 1:2-1:8, and the mass ratio of cobalt salts and melamine It is 1:1-1:6, and cooling o...

Embodiment 1

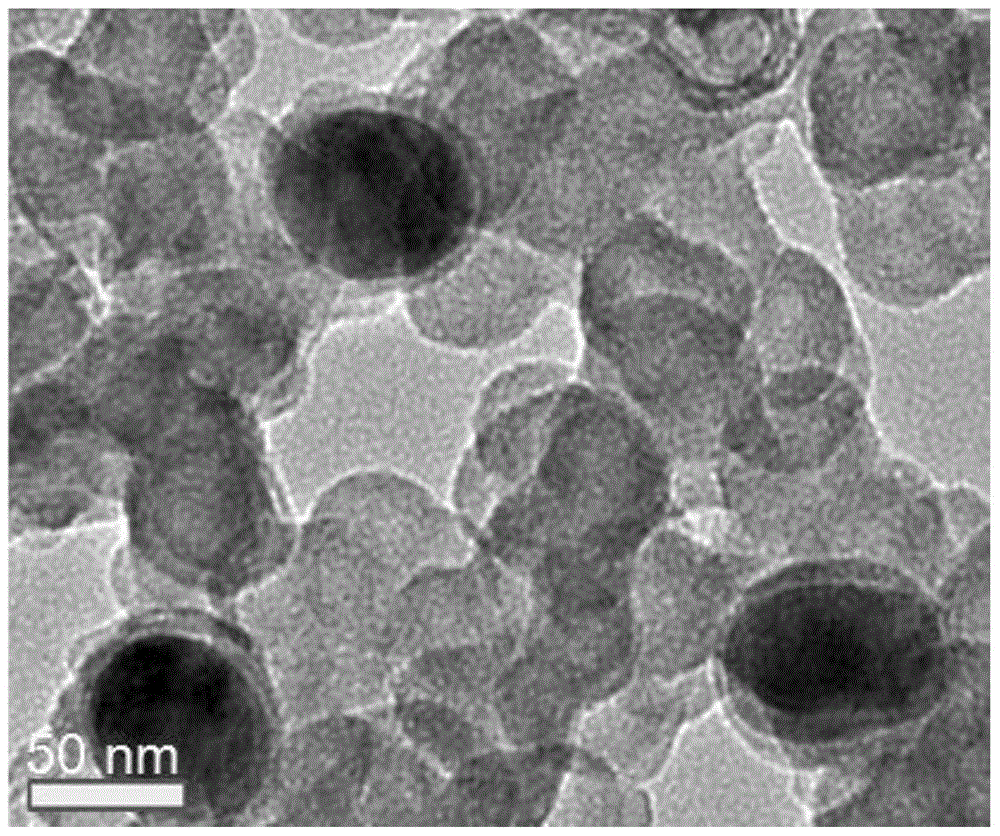

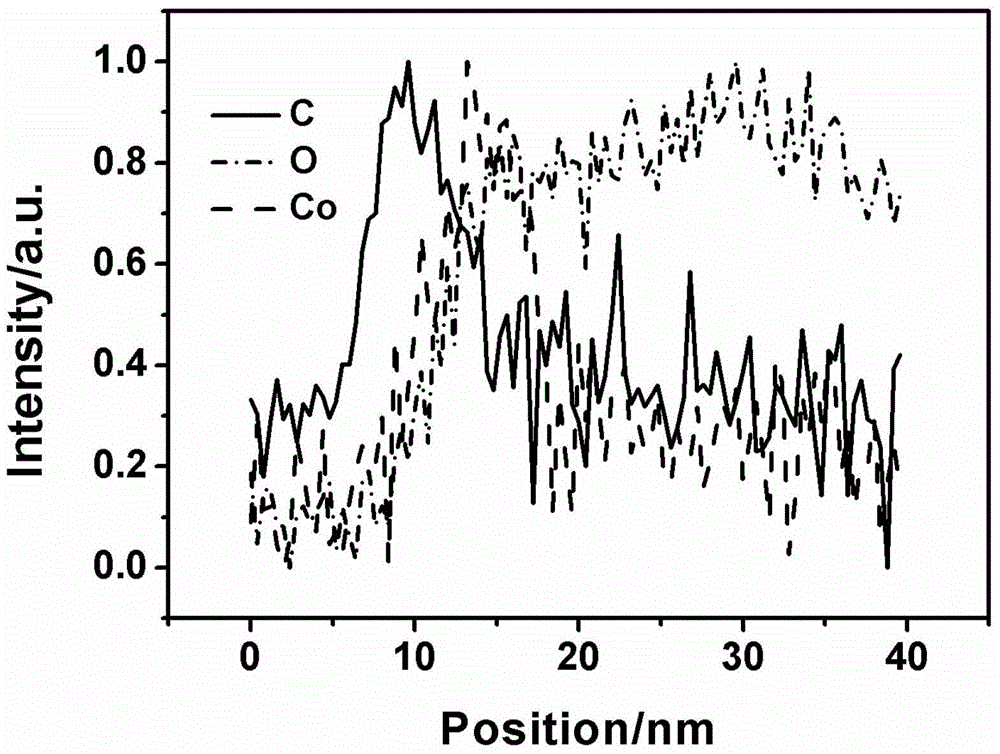

[0042] A composite material whose transmission electron microscope structure is as figure 1 As shown, it has a core-shell structure with metal cobalt as the core and Vulcan XC-72 doped with nitrogen atoms as the shell. The surface of the metal cobalt core is also uniformly wrapped with cobalt oxide. figure 2 As shown, the diameter of the core-shell structure is between 60nm and 70nm, wherein the doping amount of nitrogen atoms is 9.6%, and the mass fraction of cobalt element is 20%. image 3 shown.

[0043] The nitrogen atom is doped with pyridine nitrogen, pyrrole nitrogen and quaternary nitrogen, and its X-ray photoelectron energy fine spectrum (XPS) is as follows: Figure 4 shown.

[0044] Described composite material, its X-ray diffraction pattern (XRD) such as Figure 5 Shown, its preparation method comprises the following steps:

[0045] (1) Mix melamine and concentrated nitric acid with a concentration of 65% with water, wherein the mass ratio of melamine to concen...

Embodiment 2

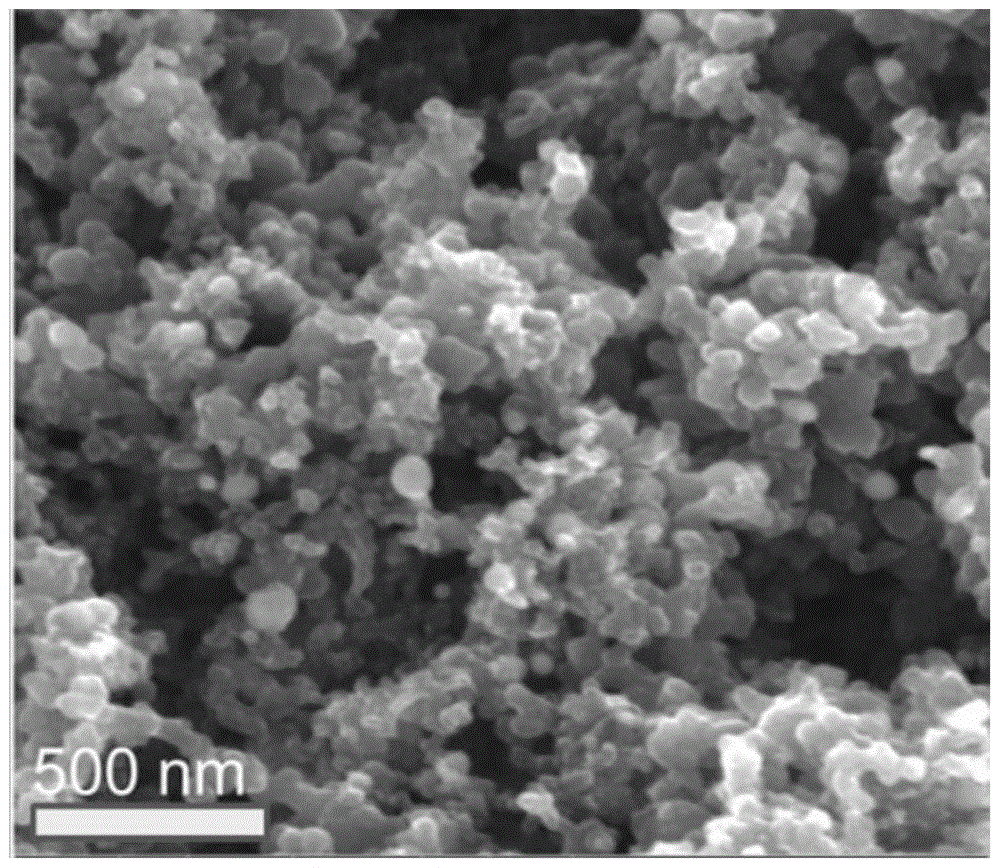

[0050] A kind of composite material, the photo of electron microscope is as follows Image 6 As shown, it has a core-shell structure with metal cobalt as the core and nitrogen atom-doped CNT as the shell. The surface of the metal cobalt core is also uniformly wrapped with cobalt oxide. The doping amount of atoms is 6.8%, and the mass fraction of cobalt element is 15%.

[0051] The nitrogen atoms are doped in the form of pyridine nitrogen, pyrrole nitrogen and quaternary nitrogen.

[0052] Described composite material, its preparation method, comprises the following steps:

[0053] (1) Mix melamine, concentrated sulfuric acid with a concentration of 98% and water, wherein the mass ratio of melamine to concentrated sulfuric acid is 1:2, and the mass ratio of melamine to water is 1:28, and heat to transparent at 70°C to obtain transparent solution;

[0054] (2) add in the transparent solution that makes in step (1), CNT and cobalt chloride mix homogeneously, wherein the mass r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com