Polyol aliphatic ester as well as preparation method and application thereof

A polypolyol and fatty acid ester technology, applied in the field of oleochemical technology and fine chemical industry, can solve the problems of low HLB value and poor emulsifying effect, and achieve the effects of good biodegradability, increased consistency and excellent emulsifying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

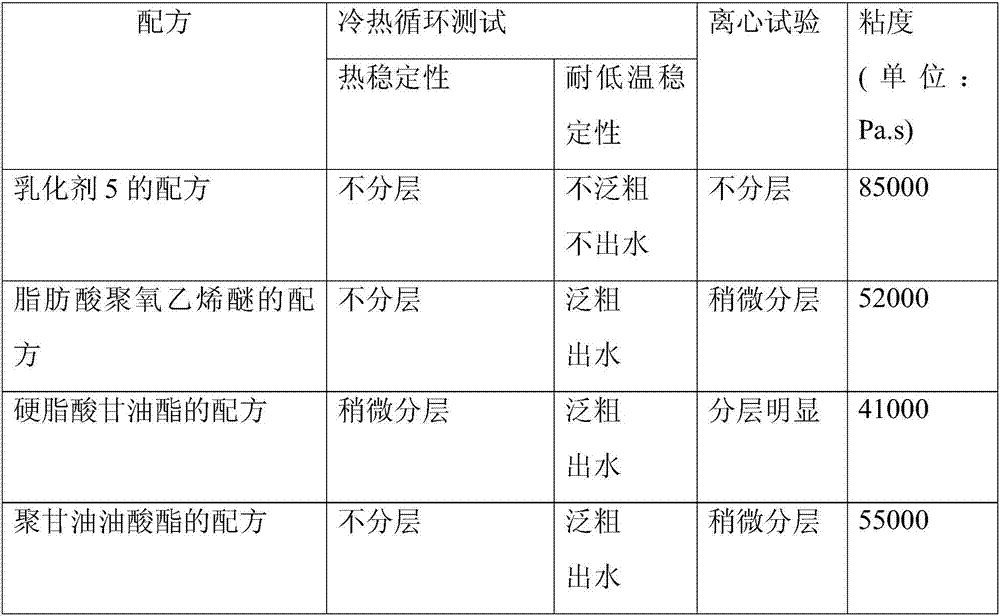

Examples

Embodiment 1

[0039] A kind of polypolyol fatty acid ester, its specific preparation steps are as follows:

[0040] Under the condition of feeding nitrogen, firstly add 300g of glycerin, 35g of trimethylolpropane, 18g of pentaerythritol and 0.4g of sodium hydroxide into the reactor, then add 8g of activated carbon and 5g of diatomaceous earth to raise the temperature to 200°C and react for 2 hours , normal pressure distillation to remove the water generated by the reaction; continue to feed nitrogen, raise the temperature to 240°C, and react for 6 hours under reduced pressure with a vacuum degree of -0.099MPa; then reduce the temperature of the material to 100°C, and turn off the vacuum , the material was filtered to obtain 300g of light yellow polyol, after testing, the hydroxyl value of this polyol was 860mgKOH / g. Then 16g octanoic acid, 10g capric acid, 10g lauric acid, 20g palmitic acid, 20g stearic acid, 124g oleic acid and 300g polypolyol are added in the reactor, then add 0.5g cataly...

Embodiment 2

[0042] A kind of polypolyol fatty acid ester, its specific preparation steps are as follows:

[0043]Under the condition of nitrogen gas, first add 210g glycerin, 105g trimethylolpropane, 35g pentaerythritol and 0.6g potassium hydroxide into the reactor, then add 10g activated clay and raise the temperature to 230°C, react for 3 hours, and distill at atmospheric pressure Remove the water generated by the reaction; continue to feed nitrogen, raise the temperature to 260°C, and react for 8 hours under reduced pressure with a vacuum degree of -0.099MPa; then reduce the temperature of the material to 100°C, turn off the vacuum, and filter the material 295 g of light yellow polyol was obtained. After testing, the hydroxyl value of the polyol was 900 mgKOH / g. Then 8g caprylic acid, 16g capric acid, 9g lauric acid, 8g palmitic acid, 9.5g stearic acid, 107g oleic acid and 295g polypolyol are added in the reactor, then add 0.7g catalyst Sn-Zn composite metal oxide, Heat up to 150°C, d...

Embodiment 3

[0045] A kind of polypolyol fatty acid ester, its specific preparation steps are as follows:

[0046] Under the condition of feeding nitrogen, firstly, 262g of glycerin, 70g of trimethylolpropane, 17.5g of pentaerythritol and 0.8g of potassium carbonate were added to the reactor, and then 12g of activated clay was added to raise the temperature to 230°C, react for 4 hours, and distill at atmospheric pressure Remove the water generated by the reaction; continue to feed nitrogen, raise the temperature to 250°C, and react for 10 hours under reduced pressure with a vacuum of -0.099MPa; then reduce the temperature of the material to 100°C, turn off the vacuum, and filter the material 298 g of light yellow polyol was obtained. After testing, the hydroxyl value of the polyol was 830 mgKOH / g. Then 9g caprylic acid, 7.6g capric acid, 6.4g lauric acid, 6.4g palmitic acid, 7.5g stearic acid, 88g oleic acid and 298g polypolyol are added to the reactor, and then 1g catalyst Sn-Zn composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com